Damage forms and countermeasures of rolls in used welded pipe machines

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-27 11:30

- Pvs:

【概要描述】The main forms of damage to the rolls of the used welded pipe machines production line are normal wear and tear and breakage.

Damage forms and countermeasures of rolls in used welded pipe machines

【概要描述】The main forms of damage to the rolls of the used welded pipe machines production line are normal wear and tear and breakage.

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-27 11:30

- Pvs:

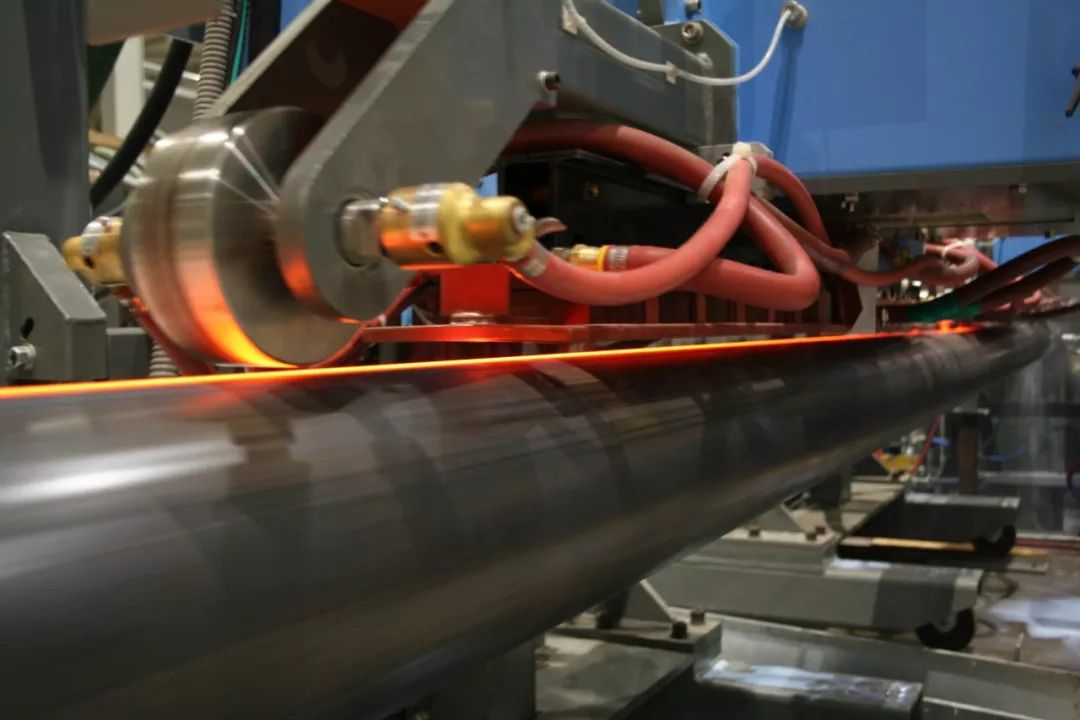

The main forms of damage to the rolls of the used welded pipe machines production line are normal wear and tear and breakage.

Normal wear and tear: The rolls are generally inspected regularly with grooved plates during use. Once the wear amount exceeds the limited range, they will be scrapped and replaced. In order to reduce the wear of the rolls, measures such as a reasonable pass pattern and an appropriate and balanced amount of extrusion for each flight can be used to ensure that the rolls are adjusted. Surface rusted roll edges cracked off blocks:

(1) Fine forming roll: When four-roll forming is used, the inner edge of the fine-forming upper roll is easily broken and damaged. This is because the assembled structure of the fine-forming upper roll is used, and the concave surface in the middle of the roll near the guide plate is stressed during the forming process of the used welded pipe machines. The largest and most prone to cracking and falling blocks. This type of damage is by far the most common. After the inner edge of the roll is cracked and damaged, a ring with a thickness of about 40mm (inner diameter 500mm, outer diameter 580mm) can be cut off from the damaged inner edge of the roll, and then a ring of the same size can be machined. After heat treatment, heat sleeved on the roll . Since the force of the upper roll during forming is from the inside to the outside, it has little effect on the force of the ring, so that the overall life of the roll is prolonged, and the use effect is not much different from that of the new roll.

When two-roll forming is used, the outer edge of the finishing roll is easy to crack and damage. Caused by unbalanced distribution. Such damage cannot be repaired, but the thickness of the edge can be appropriately increased to increase its strength.

(2) Side squeezing roller: The reason for the cracking of the upper edge of the side squeezing roller and the damage to the block is: the welding squeezing force during the adjustment of forming welding is too large, or the feed amount on both sides is uneven; The variable stress, especially at the weld of the strip joint, is higher than the base metal of the pipe body, causing the pressure to multiply when the weld passes through, causing the edge of the roll to crack. For the damage to the upper edge of the side extrusion roll caused by excessive force, the strength of the upper structure of the roll can be increased by appropriate thickening, thereby prolonging the service life.

(3) Sizing roller: The main reason for the cracking and damage of the edge of the sizing horizontal roller is: the used welded pipe machines production line is not adjusted in place during the adjustment and introduction of materials, which causes the welding seam to be twisted and skewed, just at the edge of the sizing horizontal roller. Residual external burrs at the butt or stop pipe will squeeze the edge of the roll, causing the edge of the roll to be overstressed and cracked. This damage cannot be repaired, and it is necessary to ensure that the weld is not skewed during shape adjustment to avoid roll damage.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province