Common welding defects of used high frequency welded pipe equipment (2)

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-28 11:30

- Pvs:

【概要描述】There may be various defects in the used high frequency welded pipe equipment, and the names of defects are not completely uniform. Combined with the characteristics of our welded pipe production, the defects that often occur are as follows:①Inclusions; ②Insufficient fusion; ③Stick welding; ④Cast welding;Not all of these defects are present, but they are often found in high-frequency welded pipes.

Common welding defects of used high frequency welded pipe equipment (2)

【概要描述】There may be various defects in the used high frequency welded pipe equipment, and the names of defects are not completely uniform. Combined with the characteristics of our welded pipe production, the defects that often occur are as follows:①Inclusions; ②Insufficient fusion; ③Stick welding; ④Cast welding;Not all of these defects are present, but they are often found in high-frequency welded pipes.

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-28 11:30

- Pvs:

There may be various defects in the used high frequency welded pipe equipment, and the names of defects are not completely uniform. Combined with the characteristics of our welded pipe production, the defects that often occur are as follows:

①Inclusions; ②Insufficient fusion; ③Stick welding; ④Cast welding;

Not all of these defects are present, but they are often found in high-frequency welded pipes.

The schematic diagrams provided below are not actual pictures of each defect, and are mainly used to illustrate the main characteristics of the defect, and do not mistakenly believe that welding defects are only produced under a specific process condition. The defect shown in the text is the fracture morphology of the weld cracked by the flattening test.

Common defects of insufficient fusion in the welding of used high frequency welded pipe equipment can be divided into ① incomplete fusion on the edge (cracking); ② insufficient fusion on the edge (wave on the edge); ③ insufficient fusion in the middle (internal cold welding).

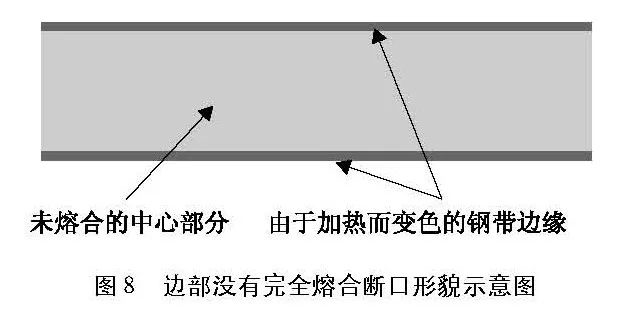

Insufficient fusion - edges not fully fused (cracking)

The edges of the two steel strips are not fully fused to form a good weld, and the cracked edges are blue, indicating that the steel strips have been heated, as shown in Figure 8.

However, the edge of the steel strip is flat and smooth, indicating that the weld is not fully fused. The most direct main reason for this type of defect is insufficient welding heating. However, considering other relevant factors, such as the angle of the V-shaped opening of the heat input to the weld and the heating length of the V-shaped opening, the installation and cooling conditions of the magnetic rod, the size of the induction coil, etc., these factors will cause defects alone or in combination.

Measures to prevent insufficient fusion:

①The welding input is matched with the characteristics of the material factory and the welding speed;

②The position of the magnetic bar exceeds the center position of the squeeze roller by 3.2 to 3.5 mm;

③ The V-shaped opening angle does not exceed the length of the pipe diameter;

④ The angle of the V-shaped mouth does not exceed 6°;

⑤ The difference between the inner diameter of the induction coil and the outer diameter of the steel pipe is not more than 6.5 mm;

⑥ The width of the steel strip is suitable to meet the requirements of the production pipe diameter.

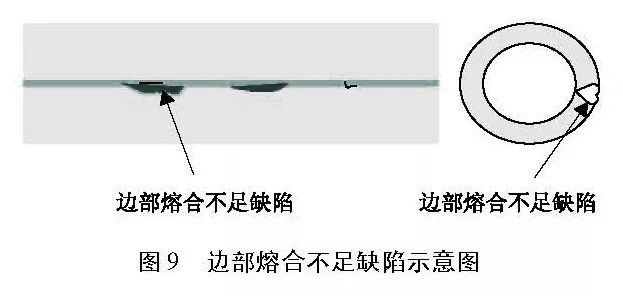

Insufficient fusion - insufficient edge fusion (edge wavy)

The cause of insufficient fusion at the edge of the weld is that there is no metal on the fusion surface. Such defects often appear on the outside or inside of the strip edge and are similar to peroxide defects. This type of defect is due to the flattening and cracking of the weld at the 3 o'clock position. As shown in Figure 9, the fracture morphology is flat and dull.

Preventive measures for insufficient edge fusion:

①The edges of the steel strips are straight and parallel butt joints;

② Use a better extrusion amount;

③ If the fracture of the defect caused by the bulge is silver-gray, use a larger welding heat input.

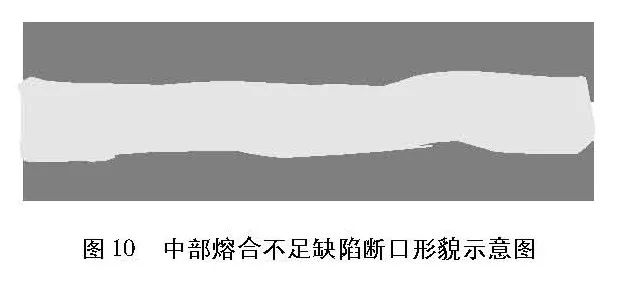

Insufficient fusion - lack of fusion in the middle (internal cold welding)

After the insufficient fusion weld is damaged, the section in the middle of the wall thickness is a flat silver-gray strip, as shown in Figure 10.

The edges are fibrous. This welding defect is caused by the fact that the power required by the welding speed exceeds the rated power amplifier of the welding machine, and the entire end edge of the steel strip does not have sufficient time to heat up to the optimum temperature and heating depth required by the weld. Insufficient fusion in the middle may also be caused by the molten metal that is not fully discharged from the joint surface due to insufficient discharge when the used high frequency welded pipe equipment is used to make pipes.

Preventive measures for insufficient fusion in the middle:

①Increase the power of the welding machine;

②Increase the amount of welding extrusion;

③ Increase the length of the V-shaped mouth or reduce the welding speed.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province