Analysis of weld cracks and cold celding defects in high frequency welded pipe machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-19 11:30

- Pvs:

【概要描述】Weld cracks and cold welding defects often occur when high frequency welded pipe machine is used to make pipes. These two problems will affect the quality of welded pipes in the production process of high frequency welded pipe machine. For this reason, we analyze these two problems. and solutions.

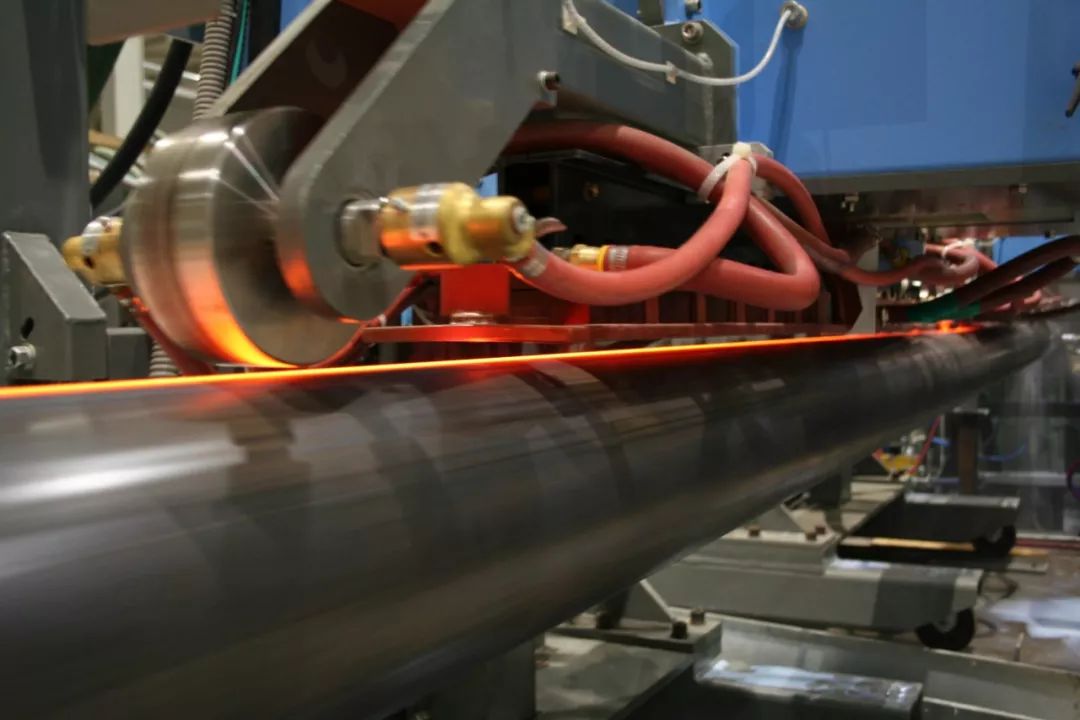

Analysis of weld cracks and cold celding defects in high frequency welded pipe machine

【概要描述】Weld cracks and cold welding defects often occur when high frequency welded pipe machine is used to make pipes. These two problems will affect the quality of welded pipes in the production process of high frequency welded pipe machine. For this reason, we analyze these two problems. and solutions.

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-19 11:30

- Pvs:

Weld cracks and cold welding defects often occur when high frequency welded pipe machine is used to make pipes. These two problems will affect the quality of welded pipes in the production process of high frequency welded pipe machine. For this reason, we analyze these two problems. and solutions.

Weld

Most of the weld cracks appear in the weld part, showing a small hair shape, and most of them occur at the superficial part of the weld; some can be seen with the naked eye, while others need to be carefully identified or even enlarged to find.

The reasons for these tiny cracks are:

(1) Reflow slag inclusion caused by high welding temperature.

(2) The tube blank is thin and narrow and the extrusion force is low, and some oxides are not extruded from the weld, and non-metallic inclusions are formed after cooling. (3) There are lack of flesh and micro-cracks on the edge of the formed tube blank.

(4) The welded seam is V-shaped butt, the superficial fusion tissue is loose, and the cooling shrinkage stress will tear the loose fusion tissue.

(5) The chemical composition of the edge of the tube blank is segregated and the oxide layer is thick, resulting in non-metallic inclusions with high melting point.

Solution: High frequency welded pipe machine can be eliminated by appropriately increasing the opening angle, increasing the extrusion force, increasing the welding temperature, and improving the edge butt state.

Cold welding

The distinguishing feature of cold welding is that there is a visible (severe) or indistinct (slight) groove or dark line on the weld. Most cold welding occurs on the outer wall of thick-walled pipes, and sometimes also on the inner wall.

The principle of cold welding is that the metal crystallization of the weld is only completed in the part of the thickness direction of the tube blank, and although the other parts are also heated by high-frequency current, the metal crystallization is not completed due to some reasons, or the metal crystallization has not been reached. condition.

Cold welding is a serious quality defect. The reasons for the cold welding of the outer wall of the welded pipe are roughly as follows:

(1) Low temperature welding

(2) Insufficient extrusion force

(3) The welding speed is too fast

(4) The magnet bar is demagnetized, the welding speed is slowly reduced, and the operator is not aware of it in time

(5) The edge of the formed tube blank is deformed, and the upper edge of the extrusion roller hole is severely worn, resulting in a sharp V-shaped butt on the edge of the tube blank

(6) Improper spraying of coolant, spray directly onto the V-shaped loop of the heating tube blank

The reasons (1) (3) (4) (6) are related to each other, the core is insufficient welding heat.

Solution: Adjust the electrical equipment of the high frequency welded pipe machine, reduce the welding speed, increase the welding heat, detect the state of the magnetic rods (cooling and arrangement), and avoid direct spraying of the coolant on the V-shaped loop of the heating tube blank.

The core of the solution is ①to reach the melting conditions of the tube blank metal. ②Increase the extrusion force and observe the burr state. ③ Strengthen the shape of the edge of the tube blank, and be sure to realize the I-shaped butt joint of the welded edge of the tube blank.

The dark line at the weld position is often misjudged as the scratch mark left by the removal of the outer burr. The first identification method is to wipe with sandpaper, and after wiping off the surface layer, the black line is still seen as cold welding; the second is to do a side flattening test.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province