Guide roller stand device for used welded pipe equipment

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-17 11:30

- Pvs:

【概要描述】Generally, the used welded pipe equipment must adjust the guide roller "as you want", which requires the guide roller frame to have a multi-dimensional adjustment function.

Guide roller stand device for used welded pipe equipment

【概要描述】Generally, the used welded pipe equipment must adjust the guide roller "as you want", which requires the guide roller frame to have a multi-dimensional adjustment function.

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-17 11:30

- Pvs:

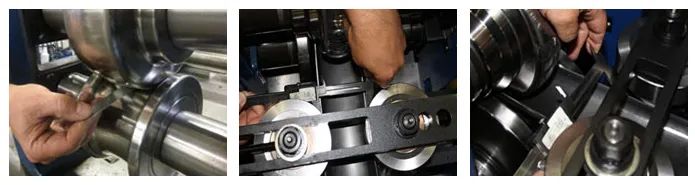

Generally, the used welded pipe equipment must adjust the guide roller "as you want", which requires the guide roller frame to have a multi-dimensional adjustment function.

How the guide roller frame works

(1) Rotate the guide roller frame to move the screw laterally, drive the laterally moving slider and the guide roller above it to move perpendicular to the rolling center line, and realize the horizontal alignment adjustment of the guide roller.

(2) Rotate the guide roller frame to adjust the screw rod up and down, drive the up and down moving slide plate and the guide roller to move up and down, and realize the position adjustment of the guide lower roller and the rolling bottom line.

(3) Rotate the guide yaw adjustment worm to drive the guide roller on the bracket to sway left and right around the rolling center line to achieve the purpose of controlling the position of the weld, which is the key to controlling the position of the weld on the special-shaped pipe. Under normal circumstances, the yaw angle of ±30° can fully meet the needs of production adjustment.

(4) Rotate the guide roller to move the nut laterally to realize the symmetrical adjustment of the hole pattern of the upper and lower guide rollers to obtain a regular basic cylindrical shape, which must be done every time the rollers are changed or one of the guide rollers is taken out. It is also a prerequisite for achieving stable welding.

(5)Tighten or loosen the adjusting screw of the guide upper roller to complete the control of the roller gap of the guide roller, and then realize the adjustment of the opening angle of the open pipe to be welded by the used welded pipe equipment. It should be noted that once the bottom line of the guide roll is adjusted in place, it is not suitable to adjust the roll gap, because it will make the guide roll higher or lower than the bottom line, which will affect the squeeze roll and its subsequent welding. bring adverse effects.

Basic requirements for guide roller stands

In addition to the above functions, the guide roller frame, as the main mechanism of the welding machine, must also meet the following 4 requirements:

(1) Good fit accuracy. It is required that each sliding part should not only cooperate closely and precisely, have no activity gap, but also ensure flexible operation. A stable guide frame mechanism is a prerequisite for stable welding.

(2) High strength and high rigidity. Theoretically, the guide roller does not undertake the task of deformation. However, due to the springback of the tube blank, the insufficient deformation of rough forming and fine forming, etc., the guide rollers on it actually have to undertake part of the deformation function, exert a certain rolling force on the tube blank, and then transform into guide rollers. The impact force of the frame, as well as the instantaneous strong impact force on the guide roller frame caused by unexpected factors such as broken joints, tube blank deviation, and ultra-thick tube blanks, all require that the guide roller frame must have sufficient strength and rigidity. The appearance is always in the "smell and dance" state.

(3) Good self-locking performance. Taking the deflection adjustment of the guide roller frame as an example, after the deflection adjustment is implemented, it is required that the deflection position is not allowed to change before the next human intervention, otherwise, the welding quality and weld position will be affected.

(4) Reserve enough space for operation. The guide roller frame assembly is one of the most frequently adjusted parts in the production process of used welded pipe equipment, and it is close to the high temperature dangerous areas such as the induction coil and the squeeze roller. Therefore, the design of the guide roller frame should consider both the convenience of operation and the change of rollers. It is convenient and leaves enough operating space for the operator; more importantly, the operator's safe operating space should be considered.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province