Welded pipe blank width consumption for pipe making by used welded pipe machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-20 11:30

- Pvs:

【概要描述】 This part of the changes are: the narrowing amount of the used welded pipe machine during the forming process, the consumption converted into internal and external burrs during the welding process, and the consumption reserved for the reduction of the diameter of the welded pipe during the sizing process.

Welded pipe blank width consumption for pipe making by used welded pipe machine

【概要描述】 This part of the changes are: the narrowing amount of the used welded pipe machine during the forming process, the consumption converted into internal and external burrs during the welding process, and the consumption reserved for the reduction of the diameter of the welded pipe during the sizing process.

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-20 11:30

- Pvs:

Precision welded pipes are inseparable from the precise tube blank width.

Under the premise of assuming constant thickness, in order to finally obtain the precise size of the welded pipe, it is necessary to consider the change of the tube blank during the forming process. This part of the changes are: the narrowing amount of the used welded pipe machine during the forming process, the consumption converted into internal and external burrs during the welding process, and the consumption reserved for the reduction of the diameter of the welded pipe during the sizing process. The sum of them is the total change of the finished welded pipe after the material is fed.

Forming allowance (reduction) + welding allowance (reduction) + sizing allowance (reduction) = total consumption

Consumption of tube blanks during forming

In the process of being rolled into an open tube (before the extrusion roll), the flat strip will be more or less elastic in the longitudinal direction due to the combined action of the longitudinal rolling tension of the forming unit and the longitudinal stretching deformation of the tube blank. and plastic elongation, although elasto-plastic compression also occurs locally in the strip, the general trend is that the elongation is greater than the compression. According to the principle of equal flow of metal per second, the width of the tube blank will inevitably become narrower in this range of rolling. The consumed width translates into the growth of the tube to be welded.

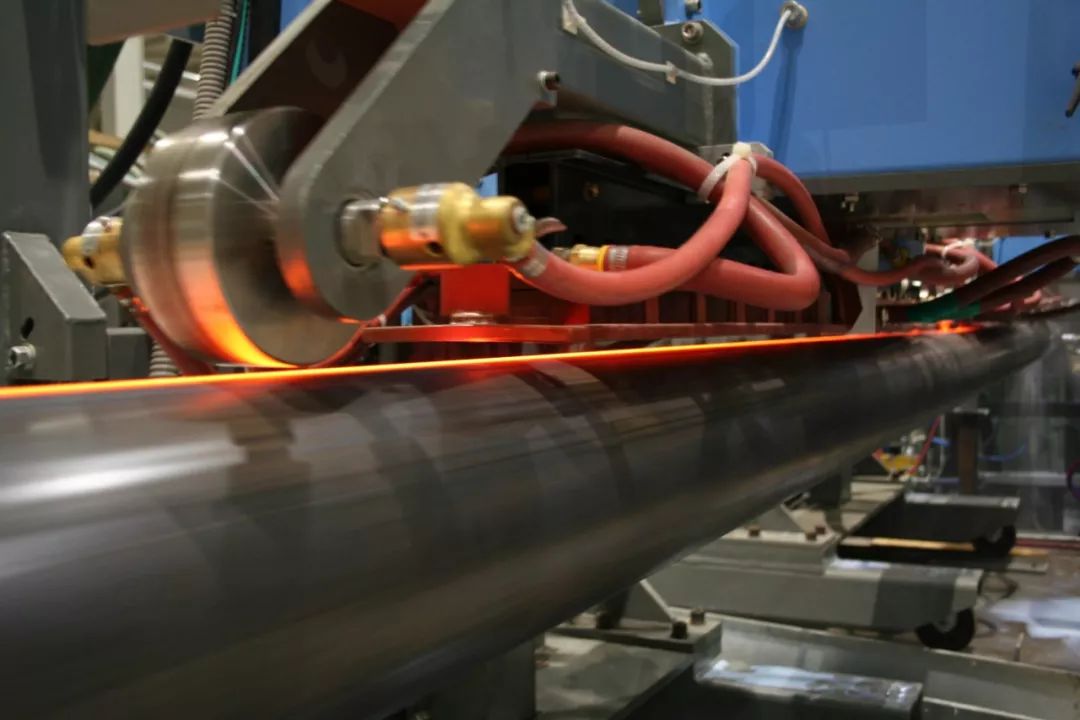

Tube blank consumption during welding

The segment welding of high frequency welding is accomplished by extruding the molten metal at the vertex of the V corner of the tube blank through the extrusion force of the extrusion roller. Used welded pipe machine In this pipe making process, some metal will inevitably be extruded. This extruded part of the metal is called the welding allowance before the extrusion roller exerts the extrusion force, which is specially designed for extrusion welding. And reserved. When the tube blank to be welded is extruded and welded, the circumference of the tube blank will be shortened under the action of the extrusion force; on the other hand, some metal will be extruded, and this part of the extruded metal will adhere to the inner and outer walls of the weld. For internal and external burrs.

Strictly speaking, the volume of welding allowance is the sum of the volume of splash steel balls formed by metal vapor during welding, the volume of internal and external burrs, and the volume of circumferential shrinkage.

It should be noted here that the spattered steel balls and the internal and external burrs are the intuitive manifestations of the welding allowance, while the invisible consumption of the circumferential compression volume is easily overlooked, which requires us to attach great importance to the unit design and production adjustment.

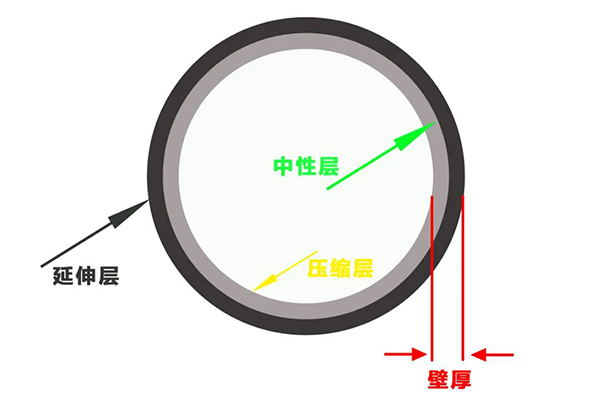

Tube blank consumption in sizing

According to the production process and shaping principle of used welded pipe machine, in order to obtain a finished pipe with a neutral layer diameter of D, it is necessary to use a welded pipe D' larger than the center diameter to be shaped for consumption. "The width of the blank tube is equal to (D'-D)π.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province