What is the common accumulation of burrs in welded pipes produced by used HFW pipe equipment?

- Sort:Information

- Auth:

- Source:

- Release time:2022-03-16 11:30

- Pvs:

【概要描述】Internal burr scraping is an important process for the production of high-frequency welded pipes by used HFW pipe equipments. Due to improper adjustment or operation, accumulation of internal burr scraping occurs during the process of scraping, which in turn affects the scraping quality of internal burrs.

What is the common accumulation of burrs in welded pipes produced by used HFW pipe equipment?

【概要描述】Internal burr scraping is an important process for the production of high-frequency welded pipes by used HFW pipe equipments. Due to improper adjustment or operation, accumulation of internal burr scraping occurs during the process of scraping, which in turn affects the scraping quality of internal burrs.

- Sort:Information

- Auth:

- Source:

- Release time:2022-03-16 11:30

- Pvs:

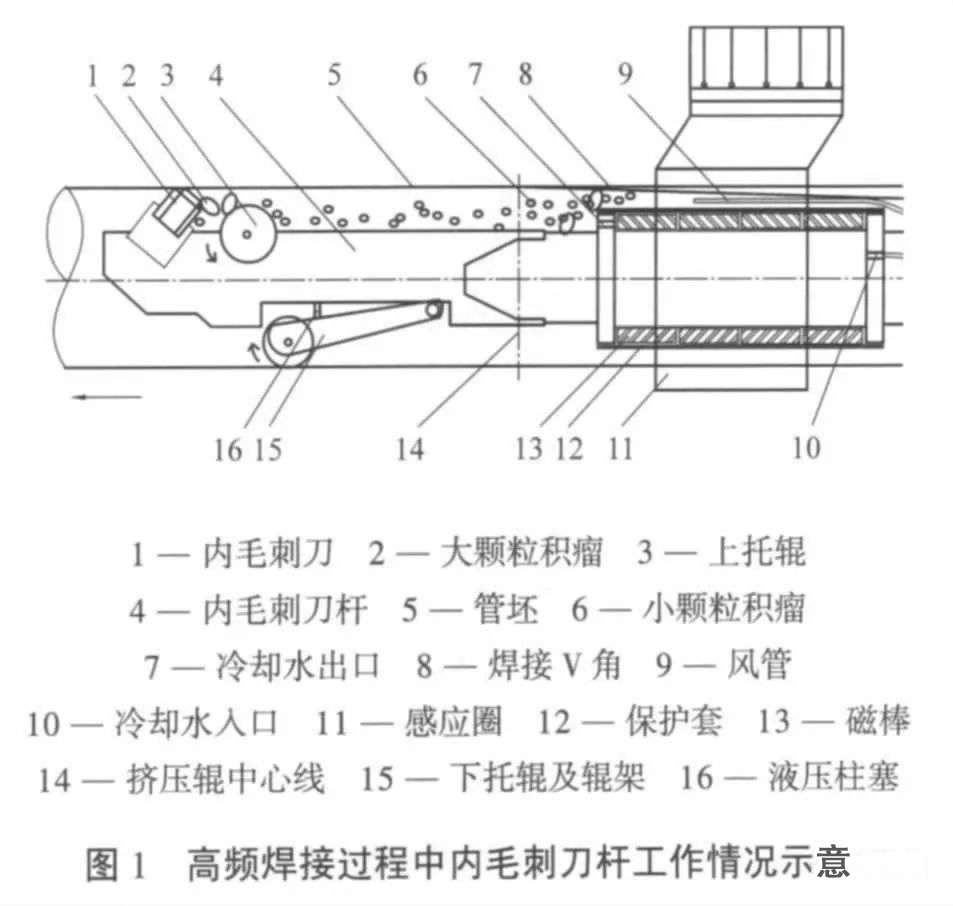

Internal burr scraping is an important process for the production of high-frequency welded pipes by used HFW pipe equipments. Due to improper adjustment or operation, accumulation of internal burr scraping occurs during the process of scraping, which in turn affects the scraping quality of internal burrs.

This paper introduces the types of build-up that appear on the burr knife or the shank in the high-frequency welded pipe, analyzes the reasons for the build-up, and prevents the build-up by observing and judging the build-up during the operation of the used HFW pipe equipments production line. resulting measures.

In the production of high-frequency welded pipes by used HFW pipe equipments, the scraping of internal burrs has always been a difficult problem to solve. The scraping quality often causes the production line to fail to operate normally and stop, which reduces the yield of welded pipes. At the same time, a large number of internal burr welded pipes exceeding the standard have brought great difficulties to the subsequent processing and seriously reduced the production efficiency. Therefore, it is necessary to analyze the accumulation problem in the process of internal burr scraping, find out the root cause of the problem, and formulate appropriate countermeasures.

There are many methods for removing burrs in high-frequency welded pipes, such as rolling method, grinding method, tool scraping method and other.

Tool scraping and deburring is widely used in production due to its high precision, flexible and convenient adjustment, and reliable quality. This paper takes the tool scraping and deburring method as an example to introduce in detail the causes and countermeasures of common accumulation problems in the production of high-frequency welded pipes .

A clear understanding of the common accumulation of burrs in the welded pipe is very important for the production line of used HFW pipe equipments. At the same time, it is also necessary to solve the problems in the production of welded pipes according to different accumulations. In the next issue, please pay attention to the types of common accumulation of internal burrs when used HFW pipe equipments produces welded pipes.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province