Welding heat cycle of high frequency welded pipe equipment

- Sort:Information

- Auth:

- Source:

- Release time:2022-05-12 11:30

- Pvs:

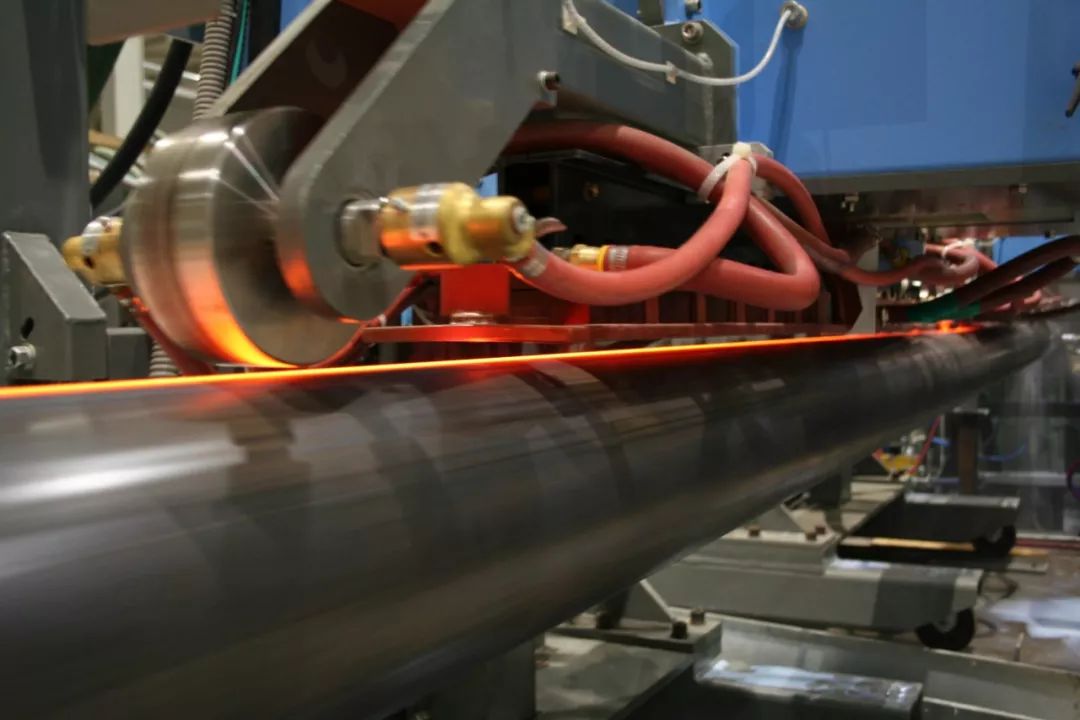

【概要描述】The welding thermal cycle of high frequency welded pipe equipment refers to the process in which the temperature of a certain point on the edge of the tube blank changes with time under the action of the heat source generated by the high-frequency welding current.

Welding heat cycle of high frequency welded pipe equipment

【概要描述】The welding thermal cycle of high frequency welded pipe equipment refers to the process in which the temperature of a certain point on the edge of the tube blank changes with time under the action of the heat source generated by the high-frequency welding current.

- Sort:Information

- Auth:

- Source:

- Release time:2022-05-12 11:30

- Pvs:

The welding thermal cycle of high frequency welded pipe equipment refers to the process in which the temperature of a certain point on the edge of the tube blank changes with time under the action of the heat source generated by the high-frequency welding current.

The welding thermal cycle reflects the thermal effect of the welding heat source on the weld and nearby metals, resulting in different microstructure and performance changes; at the same time, it also provides information for finding the best welding process, improving the weld structure by technological means, and predicting the weld stress. way.

Factors affecting the welding thermal cycle of high frequency welded pipe equipment include: ① Welding process and line energy. ②Welded pipe specifications. ③Induction coil and magnetic rod. ④ The forming quality of the forming tube blank. ⑤ Opening angle.

(1) Welding process and line energy. Under the premise that other conditions are constant and the input welding heat (power) remains unchanged, the welding speed is fast, the heating time is short, the heating width is narrow, and the cooling is fast; when the welding speed is slow, the opposite is true. These factors reflecting the welding process can be used with the help of Quantitative description of the welding heat input in the unit length of the weld - line energy:

Formula:

q=line energy, J/mm;

I=welding current, A;

U=welding voltage, V;

v=welding speed, mm/s

The line energy can comprehensively reflect the effect of welding current, welding voltage, welding speed, extrusion force, welded pipe type, running quality and other aspects on the welding seam. When the line energy increases, the heat-affected zone becomes wider, the heating time becomes longer, the oxidation area at the edge of the tube blank becomes wider, and the cooling strength increases, all of which are harmful to the quality of the weld; similarly, when the welding line energy decreases, the heating range And the heat affected zone is narrowed and the heating time is shortened, which also affects the quality of the weld.

(2) Specifications of welded pipes. An important feature of high-frequency welding current is the skin effect and uses the tube blank as a loop. When the tube to be welded is large and thick, the longer loop and the longer heat transfer path consume energy and cause other problems in the tube. Partial heating, although these are necessary, but based on the welding seam welding has no practical significance, and lead to increased line energy, affecting the thermal cycle.

(3) Induction coil and magnetic rod. The induction coil and the welded pipe are tightly coupled, that is, the gap between the induction coil and the welded pipe is small and the number of turns is matched. Active power of line energy. The function of the magnet bar is to gather as much induced current as possible to the two edges of the tube blank to be welded, so as to improve the efficiency of welding energy. In this way, only seemingly low, but active, line energy is required to complete the welding. On the contrary, if the induction coil is large, the magnetic rod is small and the magnetic permeability is low, it will lead to high frequency welded pipe equipment and more welding current will be lost in the pipe body, and less current will converge to the edge to be welded, resulting in Although the line energy is large, the actual energy used for welding is not much, which affects the thermal cycle of the tube body.

(4) The forming quality of the forming tube blank. High-quality formed tube blanks can ensure that the edges to be welded are butted in parallel, so that high-quality welding can be achieved only with low line energy. If the edges to be welded are in a V-shaped butt, the awkward shape of the two open corners inside and outside will have to make the welding heat higher and lower, and the thermal cycle curve of the welded pipe will change accordingly.

(5) Opening angle. If the opening angle is large, the proximity effect of high-frequency current is weak, the time for the tube blank to reach the welding temperature will be longer, the heating area will be wider, and the line energy will increase; on the contrary, the opening angle will be small, the current proximity effect will be strong, and the heating area of the butt welding edge will be narrow. Less line energy is required, which in turn changes the thermal cycle of the welded pipe.

In addition, the welding extrusion force, the chemical composition of the tube blank, etc., will have an impact on the actual effect of the line energy and the welding thermal cycle. Therefore, according to the above information, check whether the high frequency welded pipe equipment has those problems that affect the welding thermal cycle.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province