Welded pipe straightening method of used welded pipe units

- Sort:Information

- Auth:

- Source:

- Release time:2022-03-10 11:30

- Pvs:

【概要描述】The problem of straightening the welded pipe often occurs when the used welded pipe units is used to make pipes. For the straightening of welded pipes, we will explain to you how to make the pipes straightened by second-hand welded pipe machines. Pay attention to the following requirements.

Welded pipe straightening method of used welded pipe units

【概要描述】The problem of straightening the welded pipe often occurs when the used welded pipe units is used to make pipes. For the straightening of welded pipes, we will explain to you how to make the pipes straightened by second-hand welded pipe machines. Pay attention to the following requirements.

- Sort:Information

- Auth:

- Source:

- Release time:2022-03-10 11:30

- Pvs:

The problem of straightening the welded pipe often occurs when the used welded pipe units is used to make pipes. For the straightening of welded pipes, we will explain to you how to make the pipes straightened by used welded pipe machines. Pay attention to the following requirements.

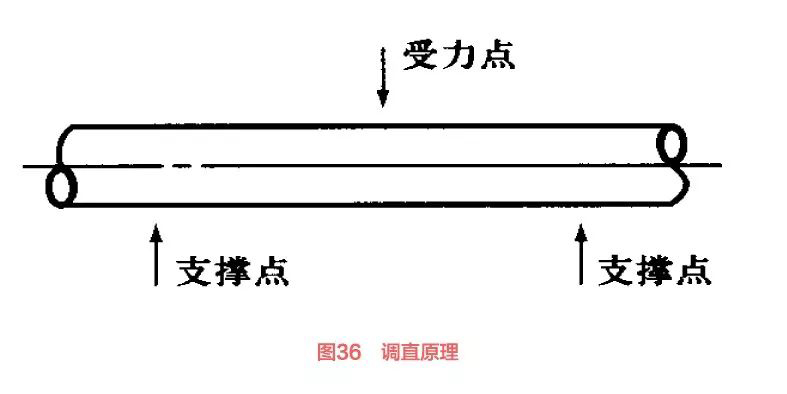

Straightening is to use the basic principle of lever (Figure 36) to re-deform the tube in the axial direction, so as to achieve the purpose of straightening.

When straightening the pipes of the used welded pipe units, pay attention to the following requirements.

(1) The force direction avoids the roll edge gap.

If the straightening roller is a four-roller structure, the stress point should avoid the gap of the roller edge when straightening, so as to prevent the pipe from drilling into the roller gap and the occurrence of "drilling the pipe" accident. In production, by adjusting the angle of the roller seat, the bottom diameter of the pass of the straightening roller can be the point of stress.

(2) Do not participate in sizing.

If the outer diameter of the tube is out of tolerance, the straightening roller should not be involved in the sizing adjustment of the tube as much as possible. Especially the straightening structure of the eight-roller type, when it is not adjusted properly, it will have bad consequences in the sizing of the pipe.

(3) Adjust the essentials.

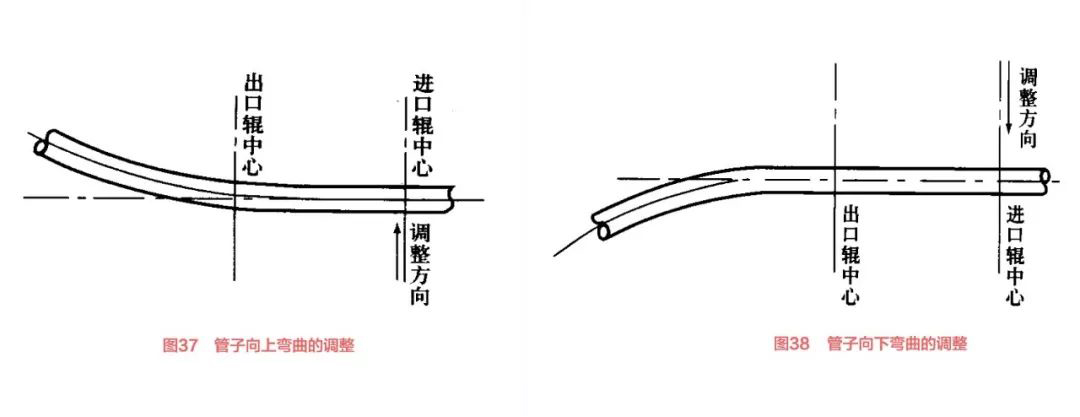

When the tube is bent, adjust the first set of straightening rollers as far as possible, and adjust less of the one set of straightening rollers at the outlet. When the tube is bent upwards, the inlet roller can be adjusted upwards (Figure 37). If the tube is bent downwards, press the inlet roller down (Figure 38).

When the tube is bent to the left or right, the inlet roller can also be adjusted to the left or right. If the used welded pipe units is still bent after adjustment, or the bending becomes more and more serious, the following six reasons need to be checked item by item.

(1) the pipe swivel;

(2) that the tube is not well cooled, and the welding seam is hot;

(3) the bearing of the straightening roller is damaged;

(4) the straightening roller mechanism is unstable;

(5) the straightening rollers are not attached to the pipe wall;

(6) the parts of the flying saw equipment are in contact with the pipe and become the redundant fulcrum in the adjustment.

After solving the above problems, you can obtain satisfactory results by adjusting and straightening.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province