Weld quality failure caused by used welded pipe units (5)

- Sort:Information

- Auth:

- Source:

- Release time:2022-03-11 11:30

- Pvs:

【概要描述】When manufacturing welded pipes for used welded pipe units, judging that the quality of the welded pipes meets the standard depends on the quality of the welds. Therefore, the quality of the weld is very important, so sometimes it is necessary to rule out the quality of the weld. We perform analyses to understand weld quality failures.

Weld quality failure caused by used welded pipe units (5)

【概要描述】When manufacturing welded pipes for used welded pipe units, judging that the quality of the welded pipes meets the standard depends on the quality of the welds. Therefore, the quality of the weld is very important, so sometimes it is necessary to rule out the quality of the weld. We perform analyses to understand weld quality failures.

- Sort:Information

- Auth:

- Source:

- Release time:2022-03-11 11:30

- Pvs:

When manufacturing welded pipes for used welded pipe units, judging that the quality of the welded pipes meets the standard depends on the quality of the welds. Therefore, the quality of the weld is very important, so sometimes it is necessary to rule out the quality of the weld. We perform analyses to understand weld quality failures.

These weld quality failures will occur when the used welded pipe units is making pipes: ① through-length lap welding. ② Periodic lap welding. ③ Open the seam. ④ Trachoma. ⑤ Peach-shaped tube. ⑥ Weld seam gnawed. ⑦Outer burr planing. ⑧ Heating. ⑨ The current is small. ⑩ Melting of induction coils and electrodes. ⑪ Fire. ⑫ "No high pressure" phenomenon. We can summarize 12 causes of weld quality failures.

Peach tube

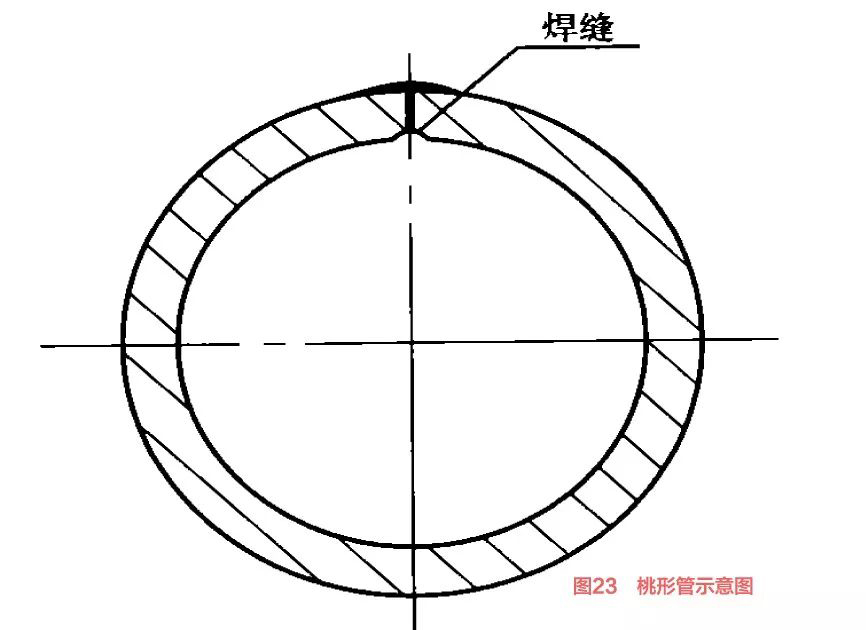

The so-called "peach-shaped" pipe means that the weld part of the pipe is protruding like a peach tip (Figure 23).

The weld of this kind of pipe is generally "eight" shape without internal burr or small internal burr. However, the amount of planing of the external burrs is generally large, and the external weld seam after planing still protrudes seriously, and the pipe surface is obviously not round. The main reasons for the "peach-shaped" tube are as follows:

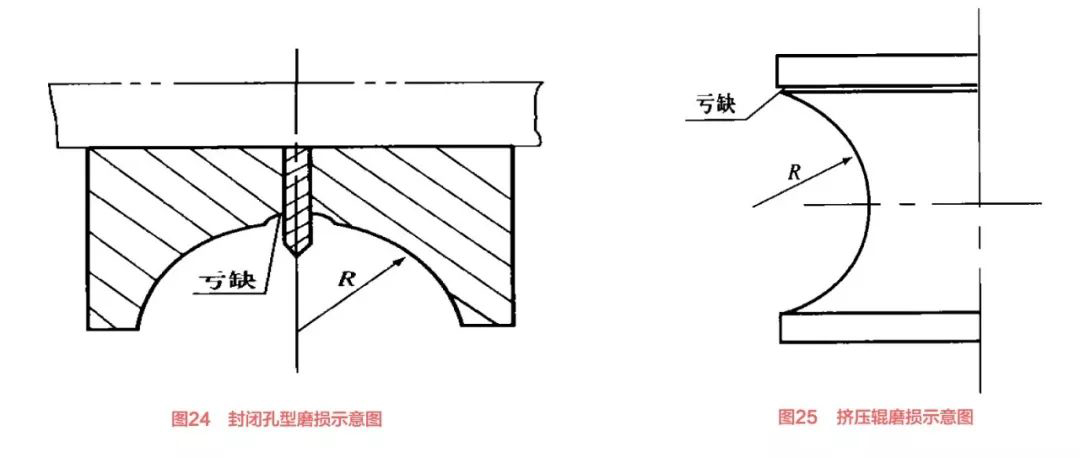

(1) Wear of the hole pattern.

The bottom diameter of the upper roller of the closed hole pattern (Fig. 24) and the upper edge of the extrusion roller hole pattern (Fig. 25) are subjected to relatively large pressure when the tube blank is deformed, and the wear is more serious. This part forms an obvious deficit, so that the weld part of the tube blank cannot be fully deformed, and a "peach-shaped" tube is formed after welding. In this case, the best solution is to replace the new hole type in time. This is also another special wear of closed hole type.

(2) Small pressing force.

The upper extrusion force is small In the two-roll extrusion roller structure, when the upper extrusion force is small, the extrusion roller shaft will form an upper elevation angle, especially in the middle and later stages of the extrusion roller use, the closed hole type When the pressure is insufficient, the probability of producing a "peach-shaped" tube is even greater. If the "peach shape" problem is not very serious, the pressure of the closed hole pattern and the upper pressure of the squeeze roller can be appropriately increased, which can be well controlled.

The above is one of the reasons for the quality failure of the weld seam when the used welded pipe units is making pipes, peach-shaped pipe. The main reasons for the formation of the peach-shaped tube are (1) wear of the hole type. (2) The upper extrusion force is small.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province