Used square pipe mill to adjust the diagonal of square and rectangular tube

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-17 11:30

- Pvs:

【概要描述】The essence of adjusting the diagonals of the used square pipe mill is to adjust the square of the square tube. In theory, if the two diagonals of the square tube are equal, the square tube is square. But not necessarily for the rectangular tube in physical form.

Used square pipe mill to adjust the diagonal of square and rectangular tube

【概要描述】The essence of adjusting the diagonals of the used square pipe mill is to adjust the square of the square tube. In theory, if the two diagonals of the square tube are equal, the square tube is square. But not necessarily for the rectangular tube in physical form.

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-17 11:30

- Pvs:

The essence of adjusting the diagonals of the used square pipe mill is to adjust the square of the square tube. In theory, if the two diagonals of the square tube are equal, the square tube is square. But not necessarily for the rectangular tube in physical form.

The premise of correct diagonal adjustment

The prerequisite for the correct diagonal adjustment of the used square pipe mill is that the theoretical diagonal length, the actual r-angle size and the measurement position determined by the hole type orientation are indispensable.

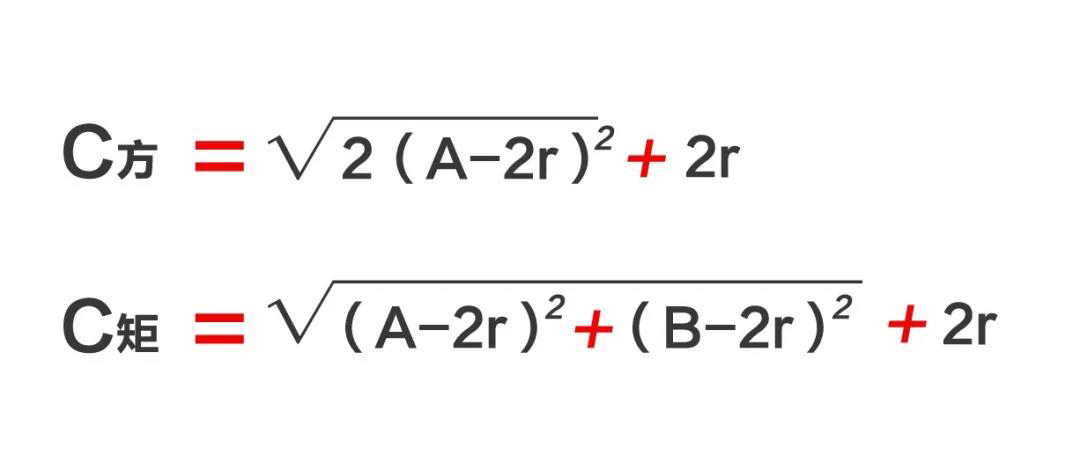

(1) Theoretical diagonal length. According to the geometric size of the square tube, the diagonal length C and C moment of the square moment management theory can be obtained as:

Before each adjustment, the theoretical diagonal length of the square rectangular tube of the corresponding specification must be calculated (or given by the process parameters), so that it can be used as a reference during adjustment.

(2) Confirm that the angle r is basically the same. Using the R gauge to measure the r-angle, according to the above formula, it can be known that only the diagonal measured when the four r-angles are basically equal in size can correctly reflect whether the rectangular tube is at right angles.

(3) The measurement position is accurate. The formula calculates the maximum value of the diagonal. If the measurement position is slightly off, then the measured size cannot truly reflect the length of the diagonal, and thus it is impossible to judge whether the tube is square.

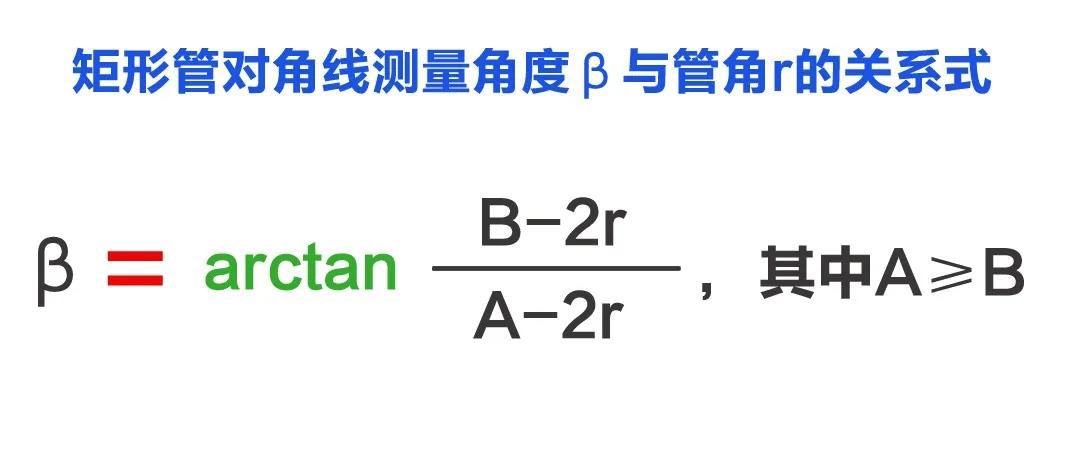

For example: when 40mm*80mm rectangular tube r=5mm, the correct measurement angle is 23.199° instead of arctan(40/80)=26.565°.

The relationship between the diagonal measurement angle β of the rectangular tube and the tube angle r is shown in the following formula:

Therefore, the method of judging the square of the square tube by measuring the diagonal can only be used as a reference.

Diagonal adjustment of rectangular tube

The upper and lower diagonals are larger than the left and right diagonals. The used square pipe mill can be adjusted in the following aspects:

(1) Properly loosen the final vertical roller (there is a flat roller afterwards). This adjustment action is suitable for fine-tuning in the production process.

(2) Properly press down the final flat roller. This adjustment measure firstly depends on whether the dimensions of the A and B sides of the rectangular tube are allowed, and it is suitable for use when the dimensions of the A and B sides are both on the wrong side.

From the above adjustment actions, we can see that special-shaped tube adjustments should pay special attention to the correlation and negative effects between the adjustment actions, as well as the positive effects.

For example, the adjustment action mode (2), if the size of A and B surface is too large, after the upper flat roller is pressed down, the purpose of reducing the diagonal line in the vertical direction can be achieved, and the size of A and B surface can be reduced by the way. Killing two birds with one stone, this is a positive effect, and can be used as the first adjustment action. On the contrary, it can only be used as a candidate adjustment measure.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province