Formation mechanism of thin-walled tube forming bulge in high frequency welded pipe production line

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-16 11:30

- Pvs:

【概要描述】The high frequency welded pipe production line is the manifestation of forming instability of thin-walled pipes, one of which is the bulge, and the bulge formation mechanism is like this.

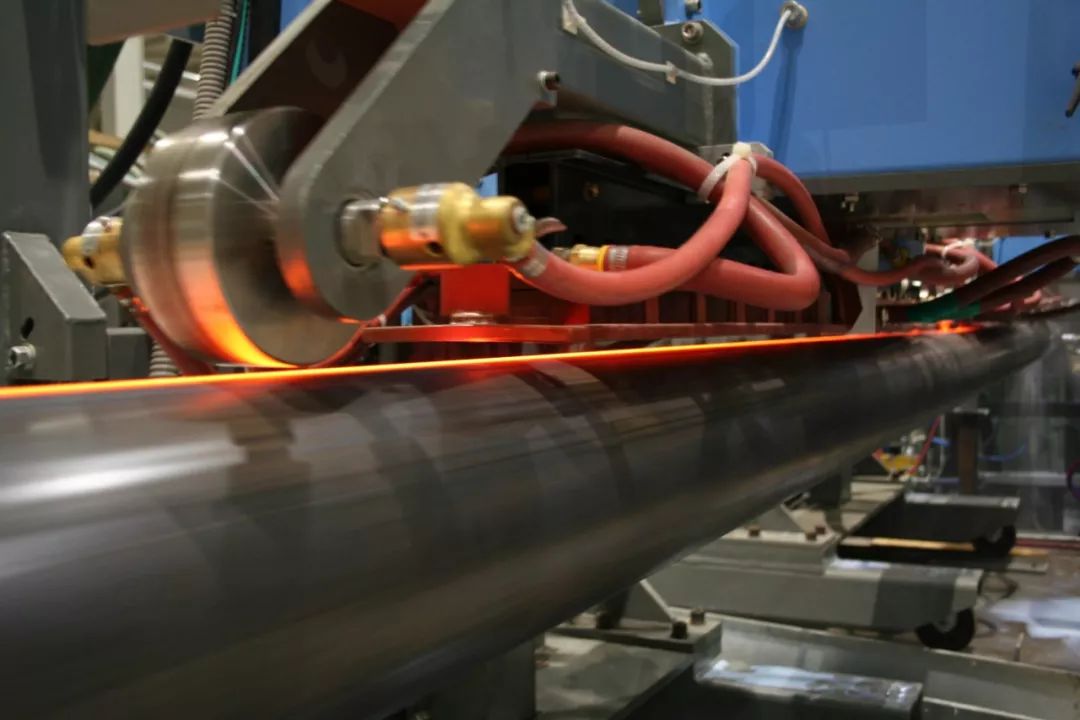

Formation mechanism of thin-walled tube forming bulge in high frequency welded pipe production line

【概要描述】The high frequency welded pipe production line is the manifestation of forming instability of thin-walled pipes, one of which is the bulge, and the bulge formation mechanism is like this.

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-16 11:30

- Pvs:

The high frequency welded pipe production line is the manifestation of forming instability of thin-walled pipes, one of which is the bulge, and the bulge formation mechanism is like this.

(1) Excessive plastic extension of the edge. According to the welding pipe forming theory of high frequency welded pipe production line, in the process of forming a flat tube into an open tube to be welded, a point on the edge gradually rises as the tube advances, and at the same time it moves closer to the rolling center surface. The trajectory of this point theoretically has a minimum value L1. L1 can only be temporarily longer than the bottom of the tube blank in a certain area of forming by △L, and △L will return to match the bottom of the tube blank with the end of forming. Length (traditionally speaking is zero). However, the forming bottom line and the rolling center line formed by the roll pass can not be an absolute straight line in fact, and the influence of factors such as tube springback, roll pass, operation adjustment and so on. In fact, the plastic extension of the edge of the tube blank in the forming process of the welded pipe is inevitable, and it is an objective existence, which can be fully proved from the deformation of the first pass and its edge elongation.

(2) The tension on the edge of the tube blank decreases sharply in the later stage of forming. The state of the longitudinal edge of the tube blank is determined by the properties of the pulling force and the restoring force: when the previous pulling force is within the elastic limit, the restoring force is the forwarding form of the previous pulling force, and forms a pair of balance forces necessary for forming with the pulling force. The edge is acted on by this pair of balancing forces, so that the edge will not easily shake and jump, that is, there will be no waves or bulges; when the previous pulling force exceeds the pulling force required for the longitudinal extension of the tube blank or due to other process reasons, operation reasons, and raw material reasons When the tensile force exceeds the elastic limit, plastic deformation of the edge will occur. Moreover, if there is no new longitudinal tensile force added, the nature of the restoring force has essentially been transformed into longitudinal compressive stress, and the edge of the tube blank will be unstable under the action of longitudinal compressive stress, and the edge will wave or even form a bulge.

It can be seen that the forming mechanism of the thin-walled tube forming bulge of the high frequency welded pipe production line is: during the forming process of the tube blank, the edge is affected by various factors and undergoes elastoplastic extension, and the edge will produce bulge when there is not enough longitudinal tension; Plastic extension and loss of longitudinal tensile stress are internal and external causes of bulging, and both are indispensable. If plastic extension occurs, but there is a large enough longitudinal tensile stress on the edge, it will not produce bulge. Similarly, if the edge does not produce longitudinal plastic extension, even if there is not enough tensile stress, it will not form a bulge. This understanding is an important result of the development of welded pipe forming theory, and it is also the theoretical basis for various advanced forming equipment, advanced forming processes and advanced forming adjustment methods.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province