Used high frequency tube mills, the development of welding pipe forming technology (2)

- Sort:Information

- Auth:

- Source:

- Release time:2023-08-24 11:30

- Pvs:

【概要描述】Used high frequency tube mills to produce welded pipe forming technology is developed in three stages according to time period and forming method: Roll Forming,Caga Forming, and Flexible Forming Excellent.

Used high frequency tube mills, the development of welding pipe forming technology (2)

【概要描述】Used high frequency tube mills to produce welded pipe forming technology is developed in three stages according to time period and forming method: Roll Forming,Caga Forming, and Flexible Forming Excellent.

- Sort:Information

- Auth:

- Source:

- Release time:2023-08-24 11:30

- Pvs:

Used high frequency tube mills to produce welded pipe forming technology is developed in three stages according to time period and forming method: Roll Forming,Caga Forming, and Flexible Forming Excellent.

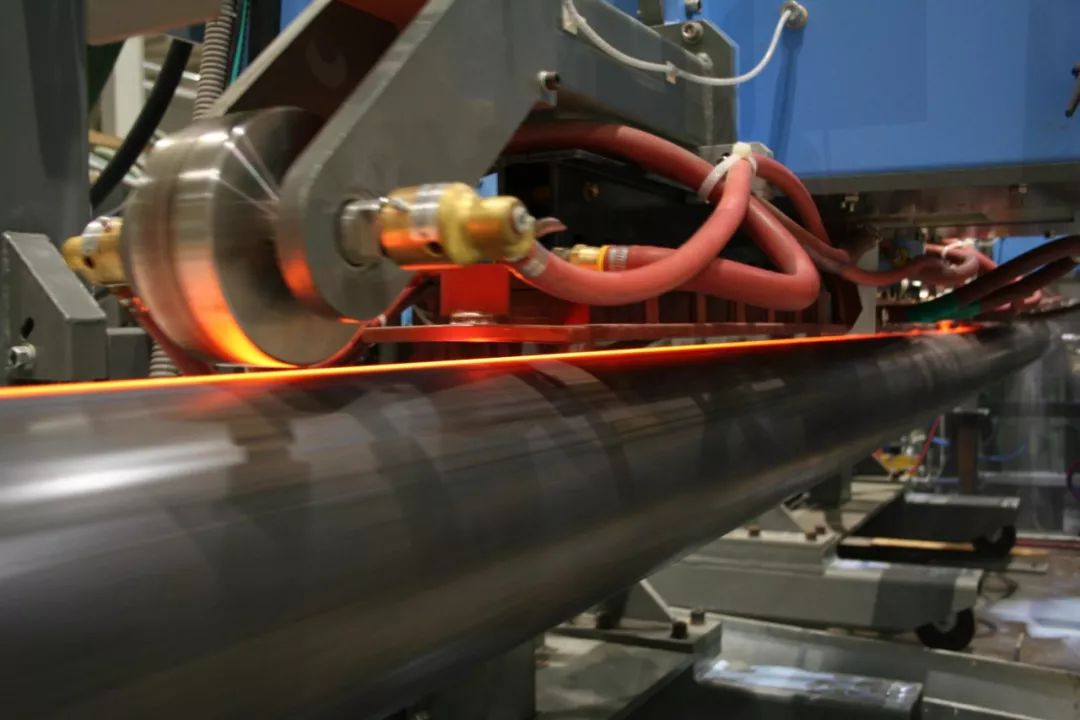

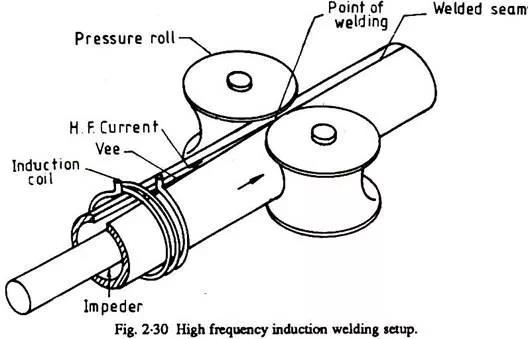

Used high frequency tube mills welded pipe forming technology includes two parts: rough forming and fine forming. It is the core of high-frequency welded pipe production technology. If the forming quality of the steel strip in the rough forming and finishing stages is not good or the forming is not in place, it is difficult to produce Produce high-quality welded pipes. Therefore, the forming technology determines the output, variety, quality, raw material and roll consumption of the high-frequency welded pipe, which is a matter of great concern to the design and manufacturing department and the user department of the welded pipe equipment.

Let's start to talk about the characteristics of these three molding technologies.

2. Roll forming technology

In view of the problems of roll forming technology, in order to reduce the number of rolls of the roll forming machine, reduce costs, and shorten the roll change time, firstly, the roll forming section of the roll forming machine adopts a Caga Foeming original technology. By the end of the 1960s, some companies improved it. At that time, the used high frequency tube mills was not very good.

Perfect, it is difficult to adjust the rolls, and the roll forming technology is only used for the production of medium-diameter welded pipes. With the passage of time, the continuous development and improvement of technology, by the late 1970s, the use of roll forming technology has gradually expanded to small diameter welded pipes.

Advantages of roll forming technology:

The number of rough forming rolls is reduced, which reduces roll costs and roll change time. The rough forming machine of row roll forming technology generally consists of two horizontal roll stands and many outer row rolls and inner rolls. For all welded pipe sizes in the product range, only one roll of the first stand is usually required, but Several sets of rolls and inner rolls are required for the second stand. Compared with the roll forming machine, the number of rolls is reduced, and the investment is also reduced accordingly.

Improve the quality of welded pipes. Many small-diameter row rolls replace the large-diameter horizontal rolls of the roll forming machine, the linear velocity difference on the roll surface is reduced, the drawing effect of the edge of the steel strip is improved, and the quality of the edge of the welded pipe is improved.

Shorten the roll change time and increase the output. Although there are several sets of rough forming rolls and inner row rolls, it is not necessary to change the rolls every time a welded pipe of one diameter is changed. The precision forming machine and the sizing machine widely use the same rigid frame and rapid roll change device, and the roll change time is greatly shortened from the past 1 to 2 shifts to tens of minutes. The roll change time is shortened and the output is increased. Therefore, the roll forming technology is not only popularized in the production of medium-diameter welded pipes, but also popularized in the production of small-diameter welded pipes. It can be said that after the mid-1980s, it was a period of great development in roll forming technology.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province