Used high frequency tube mills, the best efficiency control of the operating welding process (3)

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-27 11:30

- Pvs:

【概要描述】In the high-frequency welding of used high frequency tube mills, the welding power is generally above 100KW, and 80% of the power is consumed in the heating of the coil, the resistance, and the heating of the pressure roller and the tube blank.

Used high frequency tube mills, the best efficiency control of the operating welding process (3)

【概要描述】In the high-frequency welding of used high frequency tube mills, the welding power is generally above 100KW, and 80% of the power is consumed in the heating of the coil, the resistance, and the heating of the pressure roller and the tube blank.

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-27 11:30

- Pvs:

In the high-frequency welding of used high frequency tube mills, the welding power is generally above 100KW, and 80% of the power is consumed in the heating of the coil, the resistance, and the heating of the pressure roller and the tube blank.

Therefore, the key to minimizing power loss is to set up reasonable coils, resistors and reasonable configuration of rolling mills. In most cases, after optimizing the welding process, power loss can be reduced by 50%, and welding quality can be improved, downtime can be reduced, and output can be increased.

How to control the best efficiency of the operating and welding process of used high frequency tube mills can be divided into 8 types, and we will introduce 3 of them below: ⑥Setting of impedance device. ⑦Induction coil design. ⑧Welding frequency.

⑥ Setting of impedance.

The function of the resistor is to obtain a large current impedance in the tube, so that more current is concentrated in the V-shaped area. At the same time, the magnetic field is concentrated according to the current of the working coil, so that a large amount of current energy is concentrated in the V-shaped area of the tube.

An important parameter of the impedance device is magnetism. In use, a magnet with the highest possible magnetic flux density and oscillation, and the lowest possible electromagnetic loss should be selected. But sometimes these requirements are incompatible with each other, so the operator is required to master certain welding operation knowledge and electromagnetic circuit design knowledge.

The placement of the resistor is very important. If it is too concentrated below the confluence point, although it has higher efficiency, it is extremely easy to damage. Therefore, the resistor is generally placed in the tube so that there is a gap equivalent to the wall thickness of the tube from the inner surface of the tube. The impedance of most small units is installed at the bottom of the pipe. This placement is not only low in welding efficiency, but also easy to be dragged away when the pipe moves.

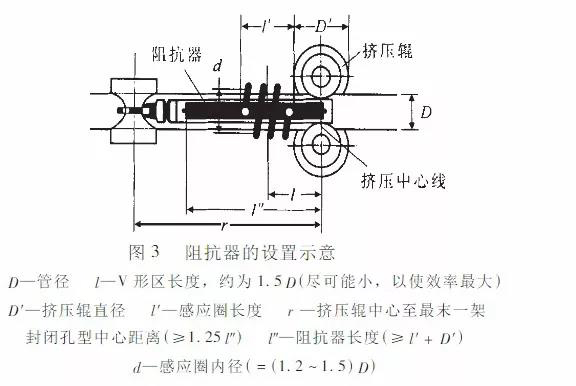

The magnetism of the resistor should extend from the center of the induction loop to the squeeze point. The minimum length of the resistor is the diameter of the squeeze roller plus the length of the induction loop. Figure 3 shows how the resistor is set up. Some operators use the front end of the resistor as the best position, and a large number of weld beads appear during welding. Although the life of the resistor is prolonged, the power consumption increases.

⑦ Induction coil design.

It is safer to use low-voltage, high-current devices in solid-state welding. Since the power consumption of the working coil is the square of the current value, even if the coil has a small resistance, there will still be a large power consumption. Therefore, in order to reduce the resistance value, the induction coil is usually made by brazing an oxygen-free copper plate and a cooling tube.

⑧ Welding frequency.

The high frequency used for welding steel pipes is between 80~800kHz. Although this frequency range has a small effect on the heating zone, it still has a direct effect on the heating quality.

The effect of impedance on the efficiency of the welding process is greater than the effect of frequency, but the loss of impedance increases with the increase of frequency, so it is more difficult to ensure the cooling of the impedance.

The high frequency is suitable for the production of small diameter pipes, and the low frequency is suitable for the production of large diameter pipes. The best way is to make the welding frequency adjustable.

The above is to control the best efficiency of the welding process of the used high frequency tube mills (3). I hope it will be of some help to you. Our company has many brands and resources, and there is always one that suits you. You only need to inform us of your pipe-making needs, and our company will provide you with used welded pipe equipments that really suits your needs. Welcome new and old customers to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province