The working principle of high frequency welded pipe machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-06 11:30

- Pvs:

【概要描述】Relatively speaking, the largest power consumption on the production line of welded pipe production enterprises is the high frequency welded pipe machine. Therefore, the efficiency of high frequency welded pipe machine directly affects the amount of energy consumption per unit of the enterprise and directly determines the production cost of the enterprise. The power consumption efficiency of high frequency welded pipe machine is restricted by many external factors. Here is the working principle of high frequency welded pipe machine.

The working principle of high frequency welded pipe machine

【概要描述】Relatively speaking, the largest power consumption on the production line of welded pipe production enterprises is the high frequency welded pipe machine. Therefore, the efficiency of high frequency welded pipe machine directly affects the amount of energy consumption per unit of the enterprise and directly determines the production cost of the enterprise. The power consumption efficiency of high frequency welded pipe machine is restricted by many external factors. Here is the working principle of high frequency welded pipe machine.

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-06 11:30

- Pvs:

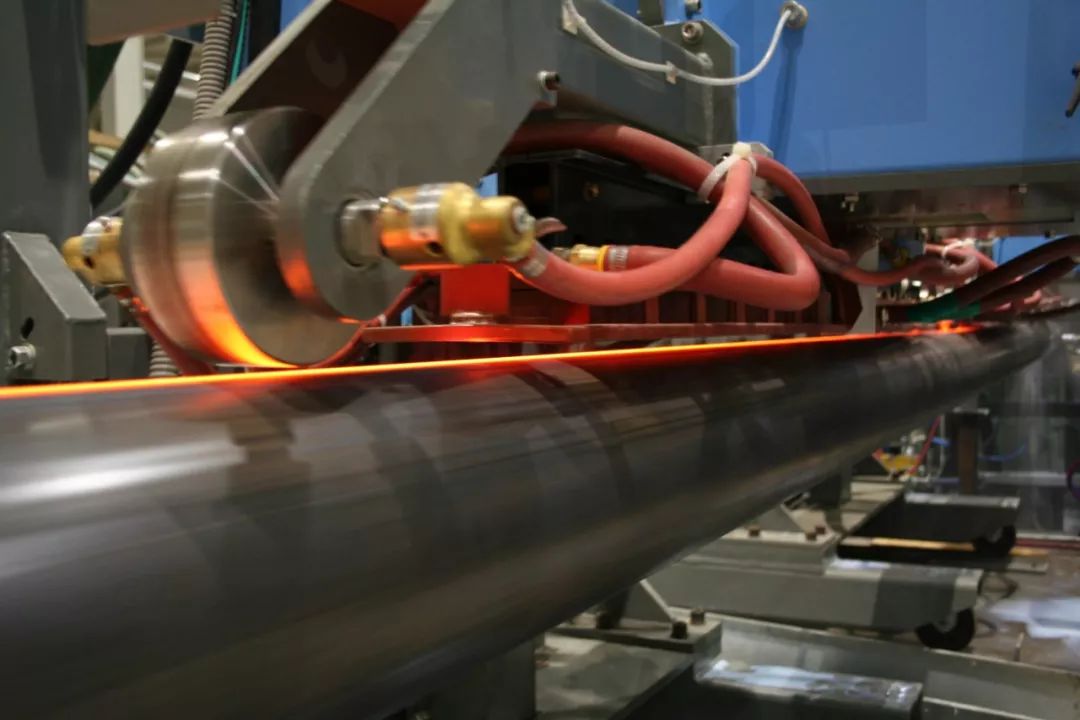

Relatively speaking, the largest power consumption on the production line of welded pipe production enterprises is the high frequency welded pipe machine. Therefore, the efficiency of high frequency welded pipe machine directly affects the amount of energy consumption per unit of the enterprise and directly determines the production cost of the enterprise. The power consumption efficiency of high frequency welded pipe machine is restricted by many external factors. Here is the working principle of high frequency welded pipe machine.

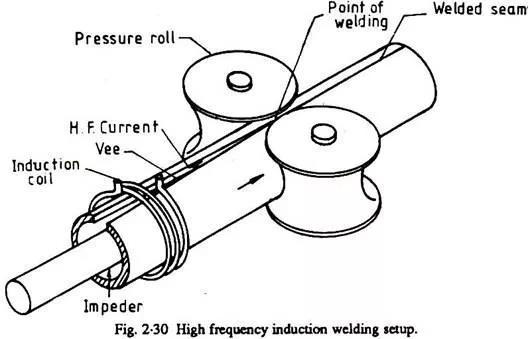

(1) Working principle of used high frequency tube mills.

The high frequency welded pipe machine consists of a set of unique electronic circuits (SCR or IGBT technology), which converts the low-frequency alternating current (50Hz) input from the grid into high-frequency alternating current (usually above 100kHz). After high-frequency current is applied to the inductance coil (ie, inductor), it is converted into a high-frequency magnetic field by the principle of electromagnetic induction, and acts on the metal object in the magnetic field. The eddy current effect is used to generate an induced current in the metal object that is proportional to the strength of the magnetic field (that is, eddy current, which is affected by the skin effect, the higher the frequency, the more concentrated on the surface of the metal object).

When the eddy current flows in a metal object, it will generate heat using the principle of electric current heating effect with the help of the inherent resistance value inside the metal object.

This kind of heat does not rely on external heat to be transferred like other heating methods. It is generated directly inside the object. Therefore, this heating method is fast and efficient. If needed, it can melt any metal in an instant. Moreover, its heating rate and temperature are controllable.

Through the working principle of high frequency welded pipe machine, we can understand that when making welded pipes, we must pay attention to controlling the heating speed and temperature and use the principle of current thermal effect to generate heat.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province