Adjustment of high-frequency welded pipe machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-07 11:30

- Pvs:

【概要描述】The high-frequency welded pipe machine is the leading equipment of the welded pipe production line. The normal operation of the unit plays a vital role in improving production efficiency, increasing economic benefits, and ensuring product quality. Therefore, the adjustment of high-frequency welded pipe machine, as well as the accurate judgment and timely treatment of faults, are particularly important. Below we focus on the following aspects to be discussed.

Adjustment of high-frequency welded pipe machine

【概要描述】The high-frequency welded pipe machine is the leading equipment of the welded pipe production line. The normal operation of the unit plays a vital role in improving production efficiency, increasing economic benefits, and ensuring product quality. Therefore, the adjustment of high-frequency welded pipe machine, as well as the accurate judgment and timely treatment of faults, are particularly important. Below we focus on the following aspects to be discussed.

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-07 11:30

- Pvs:

The high-frequency welded pipe machine is the leading equipment of the welded pipe production line. The normal operation of the unit plays a vital role in improving production efficiency, increasing economic benefits, and ensuring product quality. Therefore, the adjustment of high-frequency welded pipe machine, as well as the accurate judgment and timely treatment of faults, are particularly important. Below we focus on the following aspects to be discussed.

Adjust

The adjustment we are talking about here refers to the debugging work when the hole type is installed. As long as the tube blank can run normally and smoothly in the unit and produce qualified products, it can be said that the adjustment task has been completed. In subsequent production, a series of adjustments made should be incorporated into troubleshooting. As far as the adjustment of the high-frequency welded pipe machine is concerned, it should be divided into the following steps.

①Preparations

The preparation work mainly refers to the inspection of the quality of the rolls and the inspection of the condition of the equipment. Roll quality inspection should focus on the shape of the pass. During inspection, you can use the pass template to check whether the pass of each roll meets the design requirements, otherwise it will be removed and cannot be installed and used. In addition, special attention should be paid to the size requirements of the bottom diameter of the rolls, because this is the key data to ensure that the rolls are matched when the rolls are running synchronously. Paired rolls must be of equal size and shape. When checking the condition of the equipment, it can be summed up in the following sentences.

That is, the flat shaft should be flat, the vertical shaft should be straight, the positioning of the rolls should not move, the sliding parts should be flexible and not swing, and the adjustment should be free. The fixed part must be firm, the movable part must be flexible, and there should be no phenomenon of "moving, shaking, and back and forth". If the above requirements are not met, the equipment must be overhauled to restore its most basic performance requirements.

②Align

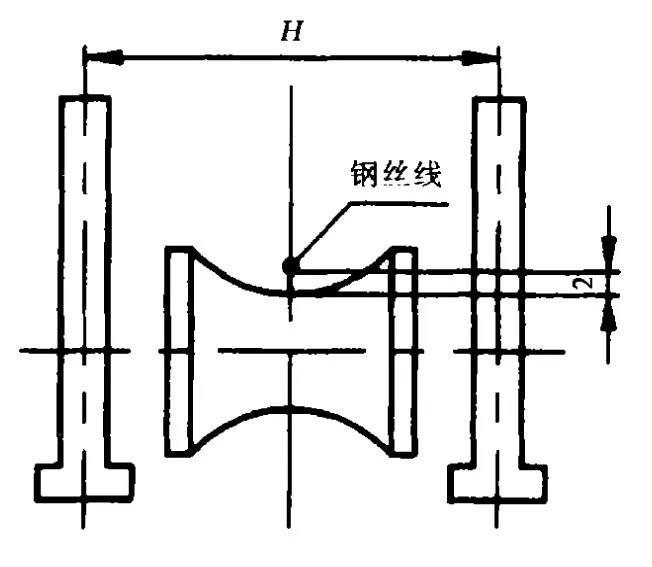

The hole pattern alignment is the first step in the adjustment work. When alignment, a steel wire of φ0.5mm can be used. The basic length is from the feeding roller of the forming machine to the straightening roller of the sizing machine to determine the rolling line. in the after the center position, tighten the steel wire to fix it. The height of the steel wire should be slightly higher than the bottom diameter of the flat roller by more than 2 mm (Figure 1). This steel wire is the center reference line when the hole pattern is aligned.

③Flat roll alignment

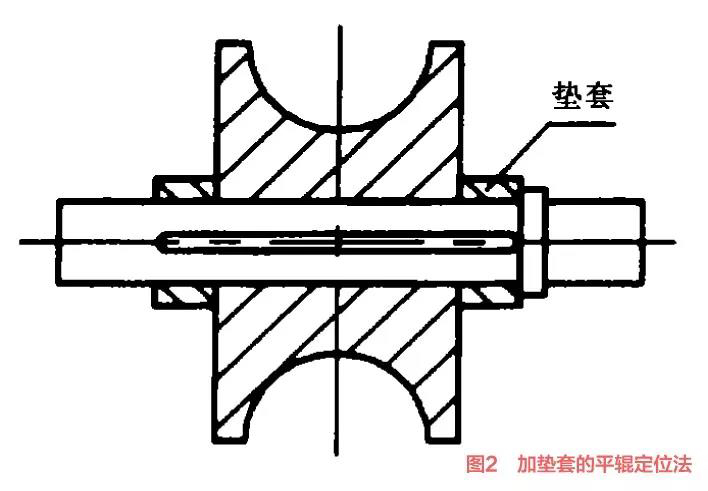

There are two alignment methods for flat rolls: one is to configure different thickness of fixed gaskets according to the thickness of each pass roll (Figure 2).

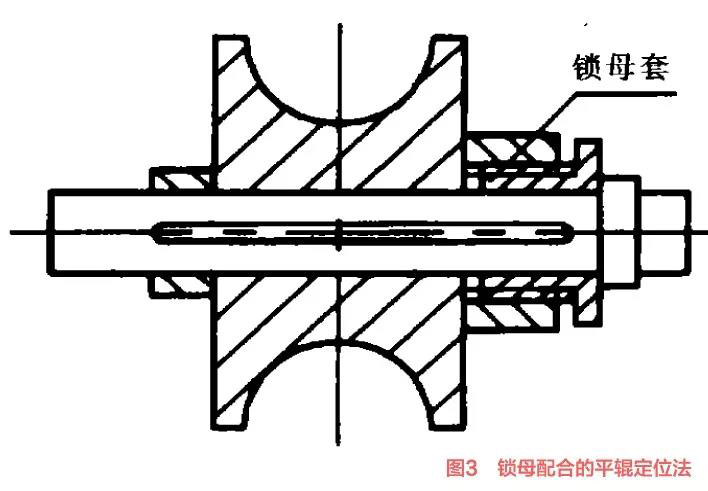

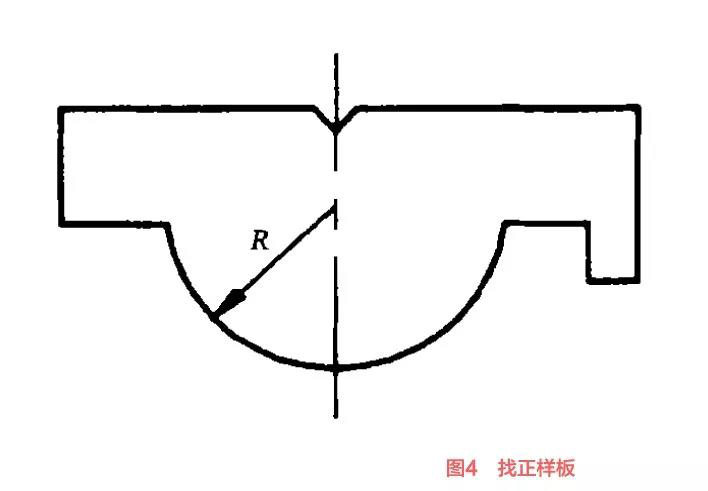

If the requirements are not met, accumulated errors are likely to occur after assembly, which directly affects the effect of hole alignment. The second is to adjust the position of the roll on the shaft with the lock nut (Figure 3), so that the center of the pass of each roll can coincide with the center line. The positioning of the center of the hole pattern is checked with a special template (Fig. 4). When checking, put the template into the aligned hole pattern, and then slowly lift the upper end. When the steel wire can smoothly fall into the center groove of the template, it means that the center position of the hole pattern is correct, otherwise it needs to do axial Mobile adjustment. This is a relatively simple way to get it right.

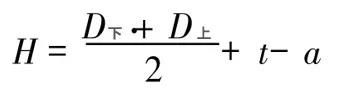

The alignment of the upper flat roll is based on the lower flat roll. After calculating the shaft distance of the upper and lower flat rollers, adjust the upper flat roller to the horizontal position. The calculation method of the shaft spacing is as follows. Calculation of shaft spacing of open hole type:

Calculation of shaft spacing for closed hole pattern:

formula:

Under D: is the bottom diameter of the lower roller, mm;

Upper D: is the outer diameter of the upper roller, mm;

t: is the thickness of the tube blank, mm;

R : is the diameter of the sizing hole, mm;

a: is the reduction coefficient (0.1~0.5).

The reduction amount of the coefficient a in the formula is mainly selected according to the thickness of the tube blank, the reduction of the outer diameter of the tube and the size of the specification, as well as the actual situation such as the shaft diameter and the elastic deformation of the shaft. However, the cold rolling phenomenon cannot occur on the forming machine. Whether the selection of the pressing amount is reasonable can be measured and checked by the pressing marks of the brazing wire. When sampling, first start the unit, drive to the slowest speed, and then bend the brazing wire with a diameter slightly larger than the thickness of the tube blank into a shape roughly similar to the hole shape, and slowly feed it into the rolling mill to obtain the indentation of the brazing wire.

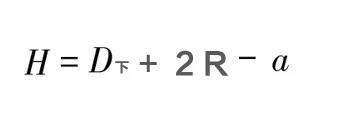

After the upper roller is leveled, the axial center position of the upper roller of the open hole pattern can also be centered with a sample plug gauge to check whether the two side clearances of the lower roller hole pattern and the upper roller hole pattern are the same (Figure 5). If the same, the axial position of the upper roller can be locked. The closed hole pattern can be touched by touch to check whether the upper and lower hole patterns are consistent.

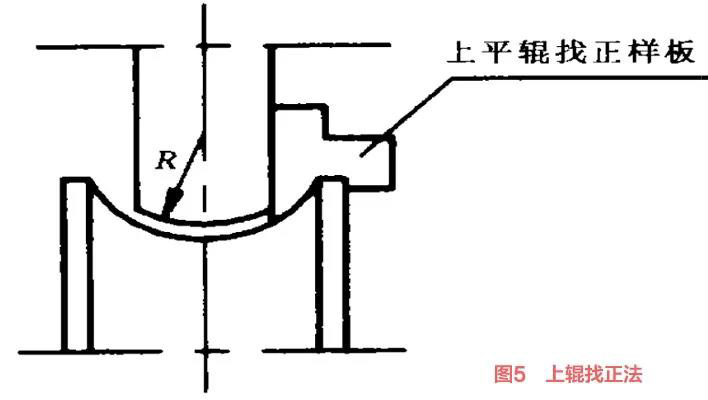

④Vertical roller alignment

Vertical roll alignment can be divided into three steps: the first step is to determine the opening gap of each set of vertical rolls, that is, the axial distance between the two vertical rolls; then find the center position of each set of vertical rolls; finally, adjust the vertical rolls high. The opening gap of the vertical roller is based on the deformation opening width in the design of the pass pattern, and then it is appropriate to shrink it by about 5 mm (Fig. 6).

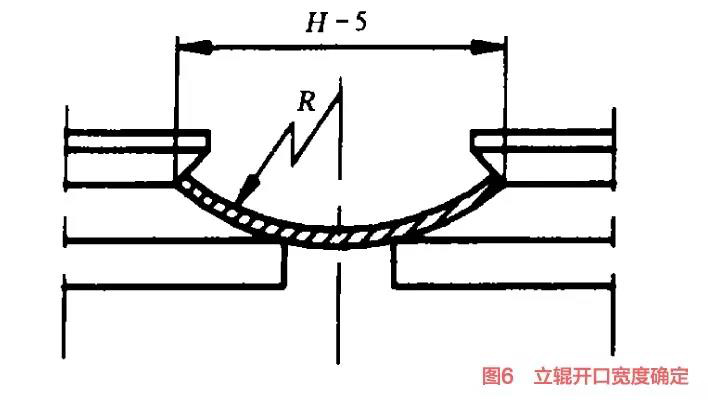

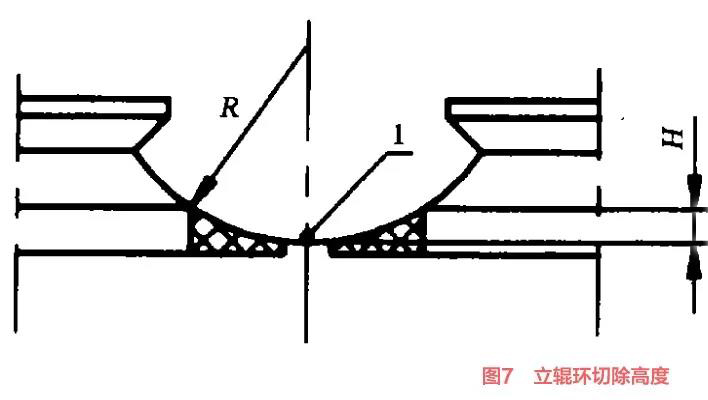

When the shrinkage is too large, the wear of the upper edge of the vertical roller hole pattern will be accelerated, and the load of the equipment will also be increased. The center of the vertical roller should be aligned with the flat roller at the same time to ensure that the center position of the vertical roller of the flat roller is on the same center line. After finding the center line of the vertical roll pass, you can drop the steel wire on the bottom diameter of the flat roll pass, and start to find the height of the vertical roll. The height of the vertical roller is based on the height of the lower edge of the vertical roller pass and the height of the steel wire (Figure 7),

The height of the vertical rollers before forming depends on the process parameters of the cut-off amount of the roller ring under the vertical roller (the part of the mesh line in the figure is the cut-off part of the roller ring).

⑤Alignment of other hole types

For other hole alignment methods, refer to the alignment principle of flat rollers and vertical rollers, except that the bottom diameter of the guide roller should be slightly higher than the reference line by 0.5-2 mm (depending on the size of the pipe diameter and depending on the wall thickness). The burr idler should be 0.5mm higher than the reference line, so that the force is more stable when the outer burr is planed, and the planing jump is prevented.

Generally, the adjustment of high-frequency welded pipe machine includes preparation work, alignment, alignment of flat rollers, alignment of vertical rollers, and alignment of other pass types, so that the normal operation of the unit can improve production efficiency, increase economic benefits, and ensure product quality. etc. have played an important role.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province