Important functions that the used HFW pipe machines must have

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-02 11:30

- Pvs:

【概要描述】The impact of steel pipes with the same wall thickness but different diameters on the used HFW pipe machines will be much greater than that of steel pipes with the same diameter and different wall thicknesses.

Important functions that the used HFW pipe machines must have

【概要描述】The impact of steel pipes with the same wall thickness but different diameters on the used HFW pipe machines will be much greater than that of steel pipes with the same diameter and different wall thicknesses.

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-02 11:30

- Pvs:

The impact of steel pipes with the same wall thickness but different diameters on the used HFW pipe machines will be much greater than that of steel pipes with the same diameter and different wall thicknesses.

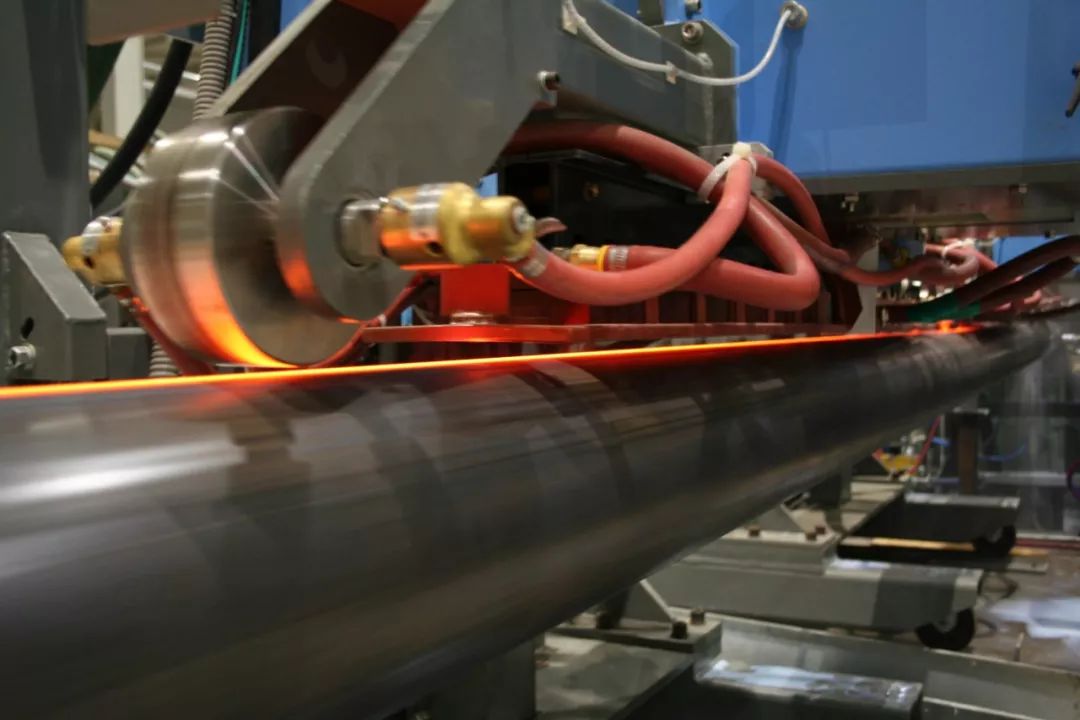

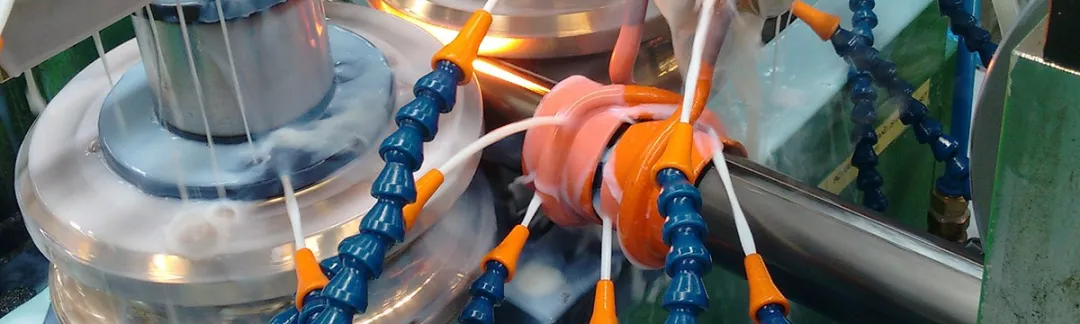

For the welding equipment of the used HFW pipe machines, the change of the pipe diameter means the change of the size of the induction heating coil, that is, the change of the output load of the welding machine equipment.

In this case, how to ensure that the welding equipment outputs the same welding frequency for the same wall thickness steel pipe is very important. The most significant role of load matching is to actively match the change of the load to ensure the same and stable welding frequency.

Configuration of used HFW pipe machines production line

Used HFW pipe machines production line welding machine power needs to be reasonably configured to reflect rationality and economy, while welding machine power and welding power are completely different concepts. Welding power is a concrete manifestation of efficiency.

The higher welding frequency reduces the welding power required for welding, improves the efficiency, and makes the welding insensitive to changes in external parameters during the production process, and the unit setting is easier than the low-frequency welding machine. At the same time, a narrower heat-affected zone can be obtained, saving raw materials.

Controlling the power of the welding machine and the welding power is an important function that the used HFW pipe machines must have.

Our company has many brands and wide resources, there is always one suitable for you. You only need to tell us your pipe manufacturing needs, our company will provide you with used welded pipe equipments that really suits your needs, welcome new and old customers to come to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province