How to improve the lubrication mechanism of the used round tube forming machines flying saw (1)

- Sort:Information

- Auth:

- Source:

- Release time:2022-03-27 11:30

- Pvs:

【概要描述】In view of the problem of insufficient lubrication of the used round tube forming machines flying saw saw car, we have 4 methods to improve it. These four methods are based on the improvement of the oil injection system, the improvement of the selection of gear and rack materials, the improvement of the selection of lubricants, and the improvement of the daily maintenance of the lubrication mechanism.

How to improve the lubrication mechanism of the used round tube forming machines flying saw (1)

【概要描述】In view of the problem of insufficient lubrication of the used round tube forming machines flying saw saw car, we have 4 methods to improve it. These four methods are based on the improvement of the oil injection system, the improvement of the selection of gear and rack materials, the improvement of the selection of lubricants, and the improvement of the daily maintenance of the lubrication mechanism.

- Sort:Information

- Auth:

- Source:

- Release time:2022-03-27 11:30

- Pvs:

In view of the problem of insufficient lubrication of the used round tube forming machines flying saw saw car, we have 4 methods to improve it. These four methods are based on the improvement of the oil injection system, the improvement of the selection of gear and rack materials, the improvement of the selection of lubricants, and the improvement of the daily maintenance of the lubrication mechanism.

Improvement of oil injection system

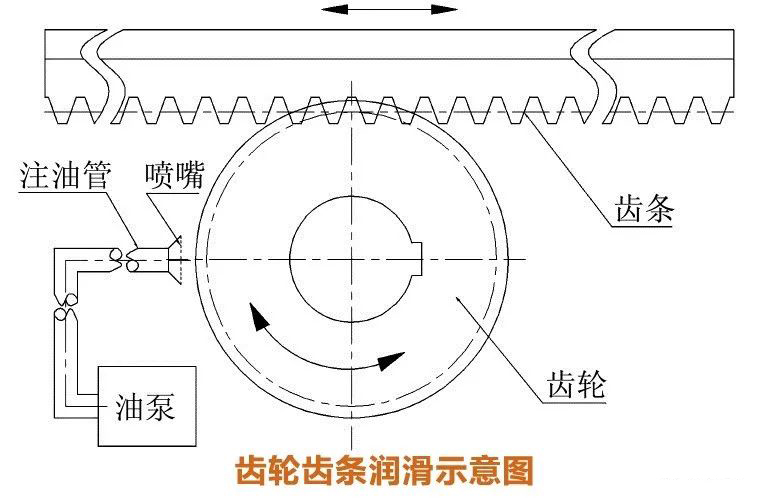

The schematic diagram of rack and pinion lubrication is shown in the figure below. The driving system of the used round tube forming machines flying saw and saw car controls the rotation direction and speed of the gear according to the actual work needs of the saw car, so as to drive the rack to do reciprocating motion that meets the actual work needs.

This technical improvement is to use the oil injection pump to regularly and quantitatively spray lubricating oil on the tooth surface of the gear fixed on the frame bed, so that the lubricating oil adheres to the tooth surface of the gear; the gear rotates, the rack and the gear move at the same time, The rack tooth surface is also adhered to the lubricating oil; the friction surface is adhered to a sufficient amount of lubricating oil to establish a lubricating oil film, so that the lubrication between the two can be effectively improved. The power supply line of the oil pump device is directly connected with the power supply unit of the saw car, that is, the saw car is powered, and the oil supply device starts timing and sprays lubricating oil. Two dustproof plates are welded on both sides of the rack to prevent the intrusion of water and dust.

Finally, an oil receiving box is set on the lower part of the gear on the machine bed, and the oil pollution in the oil box is regularly treated to prevent the remaining lubricating oil from polluting the workshop environment.

The oil injection pump used in this technical improvement is DE2232-1.5L-10KG gear oil pump. The oil pump controls the oil filling time and intermittent time of the oil pump through its internal timing element:

The oil supply time can be set to 1~120 seconds, the intermittent time can be set to 1~120 minutes, the oil supply pressure can be adjusted to 0.3~1.0MPa by controlling the pressure regulating valve, and the flow rate is 130~200mL/min; And the oil pump is equipped with a low oil level alarm, when the oil level is insufficient, an alarm can be issued in advance and the pump will be stopped. In order to achieve a good lubrication effect without wasting resources, the oil supply time is set to 20 seconds, the oil supply intermittent time is set to 40 minutes, and the oil supply pressure is set to 0.4MPa. In addition, the oil supply time, intermittent time and oil supply pressure can also be adjusted according to changes in the environment (such as seasonal changes).

The gear pump is a rotary pump that relies on the change and movement of the working volume formed between the pump cylinder and the meshing gear to transport liquid or pressurize it. Two closed spaces are composed of two gears, pump body and front and rear cover. When the gears rotate, the volume of the space on the side of the gear disengagement increases from small to large, forming a vacuum, sucking the liquid, and the volume of the space on the meshing side of the gear changes from large to large. small, and squeeze the liquid into the pipeline. The suction cavity and the discharge cavity are separated by the meshing line of two gears. The pressure at the outlet of the gear pump depends entirely on the resistance at the pump outlet.

The oil pump used in the flying saw of the used round tube forming machines is simple in operation, compact in structure, small in size, easy to maintain, reliable in operation, uniform and continuous in flow rate, small in investment and quick in effect, which can not only provide a sufficient amount of oil for the friction surface lubricating oil, and avoid excessive waste of resources.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province