How to adjust the welding process parameters of high frequency welded pipe machine(2)

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-01 11:30

- Pvs:

【概要描述】There are many factors that affect the welding process of high frequency welded pipe machine: squeeze roller, welded pipe material, welding power and frequency, welding form (induction welding and contact welding), impedance, and V angle of welding area, etc.

How to adjust the welding process parameters of high frequency welded pipe machine(2)

【概要描述】There are many factors that affect the welding process of high frequency welded pipe machine: squeeze roller, welded pipe material, welding power and frequency, welding form (induction welding and contact welding), impedance, and V angle of welding area, etc.

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-01 11:30

- Pvs:

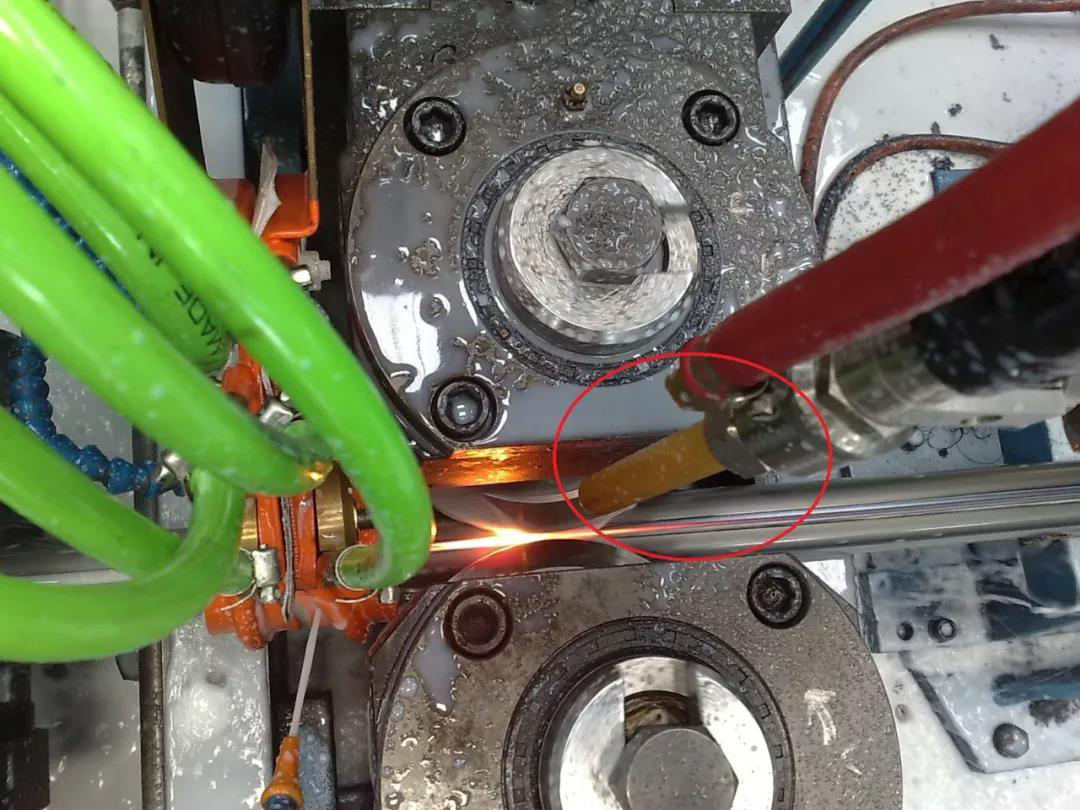

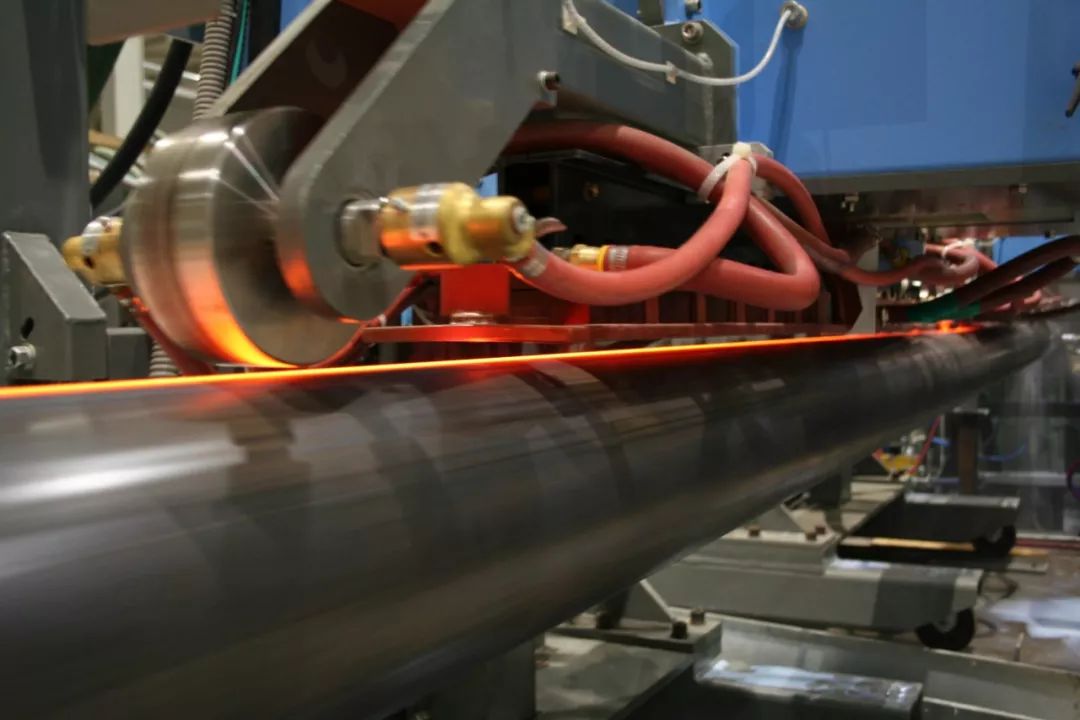

There are many factors that affect the welding process of high frequency welded pipe machine: squeeze roller, welded pipe material, welding power and frequency, welding form (induction welding and contact welding), impedance, and V angle of welding area, etc. We will learn in this issue The status and influence of welded pipe material characteristics in welding process in product debugging.

Welded pipe material characteristics What are the elements that need to be considered in the welding process of high frequency welded pipe machine? Those characteristics of the material are mainly concerned, which can be mainly divided into two categories, see the following analysis:

① Mechanical properties of the material

The mechanical properties and characteristic parameters of the base metal, such as material hardness, strength, elastic modulus, etc. These performance parameters will have different adjustment requirements for the design of the extrusion roller pass in the welding process, the requirements for the material of the rollers, the requirements for forming, the requirements for the edge counterparts entering the center of the extrusion rollers, and the materials with different extrusion force. Welding personnel need to make different adjustments according to material properties.

② Electrical, magnetic and thermal properties of materials

The electrical characteristic parameters of the base metal need to be concerned with the resistivity, magnetic permeability, thermal diffusivity and melting point of the material. According to the melting point and resistivity of the material, it can be roughly determined that different materials have requirements for the resonant current of the high-frequency power supply for welding requirements, and the current of induction welding is the eddy current of the skin effect, and the generation of the eddy current is closely related to the magnetic permeability of the material. The magnetic permeability of different materials determines the need to select the appropriate frequency of the high-frequency power supply to match it to achieve the best welding current demand.

The above two points are the material properties that need to be considered in the welding process parameters of high frequency welded pipe machine. This issue is usually considered at the beginning of the project.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province