How to adjust the convex surface of directly forming to square pipe mill when manufacturing square and rectangular pipes ?

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-02 10:49

- Pvs:

【概要描述】When the directly forming to square pipe mill is used to manufacture the square pipe, the convex surface of the square pipe will cause the tolerance size, square tube shape, etc. to lose the angle measurement benchmark and size adjustment benchmark, and it is impossible to judge the true condition of the welded pipe.

How to adjust the convex surface of directly forming to square pipe mill when manufacturing square and rectangular pipes ?

【概要描述】When the directly forming to square pipe mill is used to manufacture the square pipe, the convex surface of the square pipe will cause the tolerance size, square tube shape, etc. to lose the angle measurement benchmark and size adjustment benchmark, and it is impossible to judge the true condition of the welded pipe.

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-02 10:49

- Pvs:

When the directly forming to square pipe mill is used to manufacture the square pipe, the convex surface of the square pipe will cause the tolerance size, square tube shape, etc. to lose the angle measurement benchmark and size adjustment benchmark, and it is impossible to judge the true condition of the welded pipe.

Eliminating the convex surface of the tube is the premise of controlling the basic size of the square tube. There are four situations that affect the convex surface of square and rectangular pipes made by directly forming to square pipe mill. Different convex surfaces have different formation mechanisms and different adjustment methods. Let's analyze it below.

Convex on all sides

The reason for the quadrilateral convexity is:

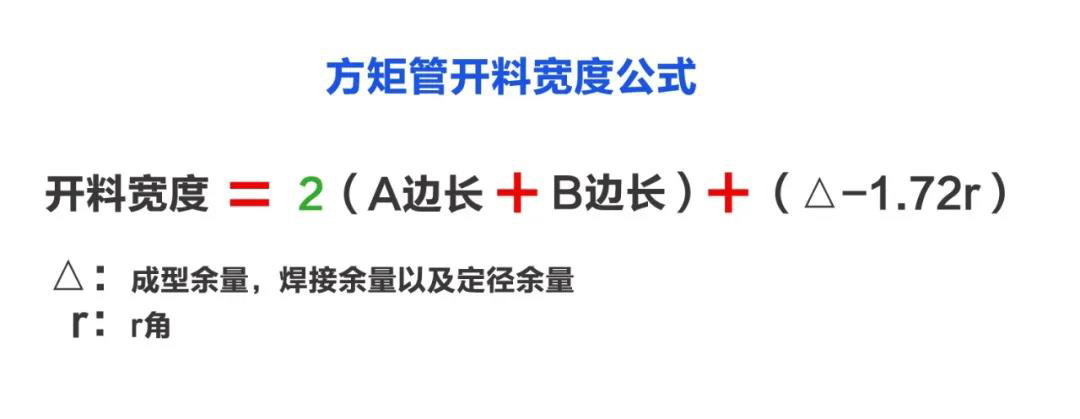

(1) The width of the material is not large enough, so that the material cannot be filled with the hole type. The formula for the cutting width of the square rectangular tube is as follows:

(2) The pipe entering the sizing section is not large enough. In the case of sufficient cutting material, if the forming allowance and welding allowance of the front section are excessively consumed, the sizing allowance after entering the sizing will become smaller.

(3) Improper allocation of sizing allowance. The first few passes are pressed too much, so that most of the sizing allowance is consumed by the first few passes, so that there is no material available for subsequent deformation. It should be noted that this situation is easy to cause misjudgment, thinking that the problem is that the cutting width is not enough, but it is actually the allocation of the sizing allowance.

(4) The pipe is hard. The square and rectangular tube surface is flat in the final pass. After leaving the constraints of the pass, the tube surface rebounds into a convex surface under the action of rebound inertia.

(5) The tube wall is thin. When producing square and rectangular tubes with the same nominal size but different wall thicknesses, the thin-walled tube is more likely to have a convex surface than the thick-walled tube, which is related to the insignificant effect of the neutral layer of the thin-walled tube.

(6) The hole type is seriously worn. Judging from the working state and force of the pass, the first contact with the pipe on the round-to-square pass is the midpoint of the arc of each pass. Easy to bulge.

For the square and rectangular tubes with four sides convex, corresponding measures must be taken to eliminate them according to the specific reasons.

(1) Properly increase the opening width. Especially in the trial production of special-shaped pipes of new specifications, the width of the materials must be based on the principle of "rather wide than narrow".

(2) Strictly control the process allowance of each section. Make enough sizing margin when entering the sizing section.

(3) Reasonably allocate the sizing allowance in the sizing section.It must be ensured that at least the last three pass patterns are available with sufficient material.

(4) The final deformed roller should use a reverse deformation pass.According to the principle that overcorrection must be overcorrected, for the convex surface caused by hard material, thin material, wide side length, etc., the reverse deformation pass can be used to excessively roll the convex tube to ensure that the tube surface just returns after leaving the pass. Bounce into a flat surface.

(5) Double plane hole type. That is to say, the pass patterns of the final vertical roll and the flat roll are all designed according to the flat pass pattern. This method is more effective in deforming thick-walled square and rectangular tubes, and is most widely used.

(6) Negative difference method.For the narrow material that has been opened, the square and rectangular tube can be adjusted according to the negative tolerance under the premise of the standard permit or the customer's acceptance, which is equivalent to increasing the bandwidth.

(7) Repair of hole type. It is found that the hole pattern wears and becomes concave, and can be repaired for individual hole patterns with severe wear; relatively speaking, the repair frequency of the last hole pattern is higher, but the amount of trimming is mostly small.

Three-sided convex. The reason is similar to that of the quadrilateral convexity, and will not be repeated here.

Convex on both sides. There are two types of two-sided convexity, namely, the adjacent side convexity and the opposite side convexity.

The following table gives some basic reasons and adjustment measures for representative adjacent and opposite convexities. (Double-click to enlarge to view or save)

One-sided convex.

The phenomenon of the single-sided convexity of the rectangular tube is not common in the oblique hole pattern, and it is essentially a masked two-sided convexity. Single-sided convexity mostly occurs on square and rectangular tubes produced with box-type passes and four-segment arc-disjoint passes.

Its formation mechanism is different from the oblique hole pattern. If the left side of the rectangular tube produced with four disjoint arc holes is convex, then one of the possible reasons is that the left side of the first upper and lower rollers is too pressed. Too much, resulting in the short left side when the material is divided.

In terms of adjustment convenience and flexibility, the four-segment non-intersecting arc hole pattern is higher than the oblique hole pattern and the box-type hole pattern, provided that you are familiar with the application and find out the reason.

The above are for the adjustment of the convex surface of the square tube in the manufacture of directly forming to square pipe mill and the four situations that affect the convex surface of the square tube. I hope you can pay attention to it.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province