Frequently asked questions about high-frequency welding of high frequency welded pipe equipment (2) - how to judge the edge shape of the strip

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-01 11:30

- Pvs:

【概要描述】The high frequency welded pipe equipment is the core equipment of the entire HFW production line, and it is also the equipment with the highest technical requirements.

Frequently asked questions about high-frequency welding of high frequency welded pipe equipment (2) - how to judge the edge shape of the strip

【概要描述】The high frequency welded pipe equipment is the core equipment of the entire HFW production line, and it is also the equipment with the highest technical requirements.

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-01 11:30

- Pvs:

The high frequency welded pipe equipment is the core equipment of the entire HFW production line, and it is also the equipment with the highest technical requirements. If it is adjusted improperly, it will directly affect the quality of the welded pipe. This article takes five-roll extrusion welding as an example to introduce the high frequency welded pipe equipment in detail. Common problems of high-frequency welding of machines (2)--How to judge the shape of the strip edge.

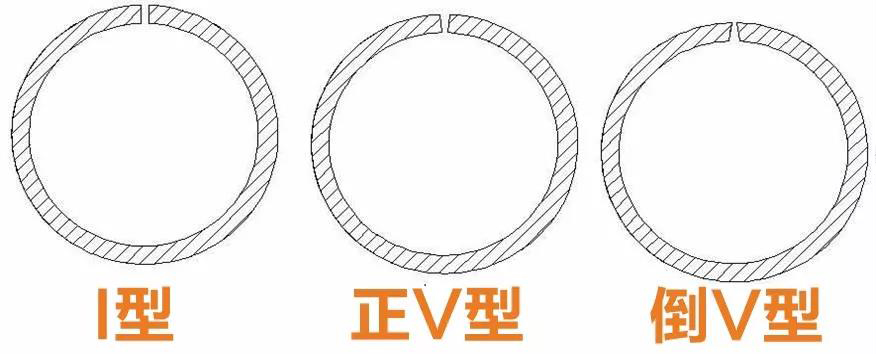

Strip edge forming form

Method for judging the shape of the strip edge of the high frequency welded pipe equipment:

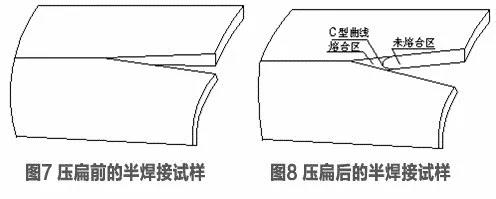

① Semi-welding test

Take a half-welded sample at high frequency. The so-called half-welded sample is the transition from the butt-welded plate edge to the welded fusion state.

Using a flattening test machine, the semi-welded sample was fractured along the weld direction, revealing two brightly colored areas: the welded fusion zone and the unfused zone (Figure 8). The fracture of the fusion zone was silver-white, and the unfused zone was blue-black. The junction of the two areas is a C-shaped curve.

②Observe the degree of the upper and lower streamline angles of high-frequency welding metallography.

Generally, the lower streamline angle is larger than the upper streamline angle, which is a positive V-shape, the upper streamline angle is equal or close to the I-shape, and the upper streamline angle is larger than the lower streamline angle and is an inverted V-shape.

The above problems are how to judge the shape of the strip edge during high-frequency welding of the high frequency welded pipe equipment. I hope to give you effective help.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province