Solutions to Difficulties in Thick-walled Pipe Forming of directly forming to square pipe mill(3)

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-31 11:30

- Pvs:

【概要描述】Solutions to solve the difficulties in forming thick-walled tubes of directly forming to square pipe mill include special forming unit solutions, rough forming pass solutions, fine forming pass solutions and comprehensive solutions. Let me first introduce the precision forming pass solution (3) and the comprehensive solution.

Solutions to Difficulties in Thick-walled Pipe Forming of directly forming to square pipe mill(3)

【概要描述】Solutions to solve the difficulties in forming thick-walled tubes of directly forming to square pipe mill include special forming unit solutions, rough forming pass solutions, fine forming pass solutions and comprehensive solutions. Let me first introduce the precision forming pass solution (3) and the comprehensive solution.

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-31 11:30

- Pvs:

Solutions to solve the difficulties in forming thick-walled tubes of directly forming to square pipe mill include special forming unit solutions, rough forming pass solutions, fine forming pass solutions and comprehensive solutions. Let me first introduce the precision forming pass solution (3) and the comprehensive solution.

Precision forming pass solution (3)

The directly forming to square pipe mill is required to increase the deformation of the edge of the tube blank under the condition of making a round, precision-formed closed pass, and it is also difficult to reduce the diameter without excessive reduction. However, this process goal can be achieved by adopting a flat oval precision forming closed hole type. The forming idea of the flat ellipse closed pass is: "flat ellipse + springback = circle", so that the thick-walled tube can be fully deformed in the flat ellipse closed pass. At the same time, it is beneficial for the tube blank to smoothly enter the hole pattern and reduce the difficulty of operation.

If you want to solve the directly forming to square pipe mill precision forming pass, you must know the following information:

1.The connotation of the flat oval closed pass.

2.The function of the flat ellipse closed hole type.

3.The design principle of flat ellipse closed hole type.

The following first introduces the function of the flat ellipse closed hole type and the design principle of the flat ellipse closed hole type.

(2) The function of the flat ellipse closed hole type. In addition to having all the functions of the closed hole type, the flat ellipse closed hole type has its outstanding function in that it can force the edge of the high-strength thick-walled pipe to deform.

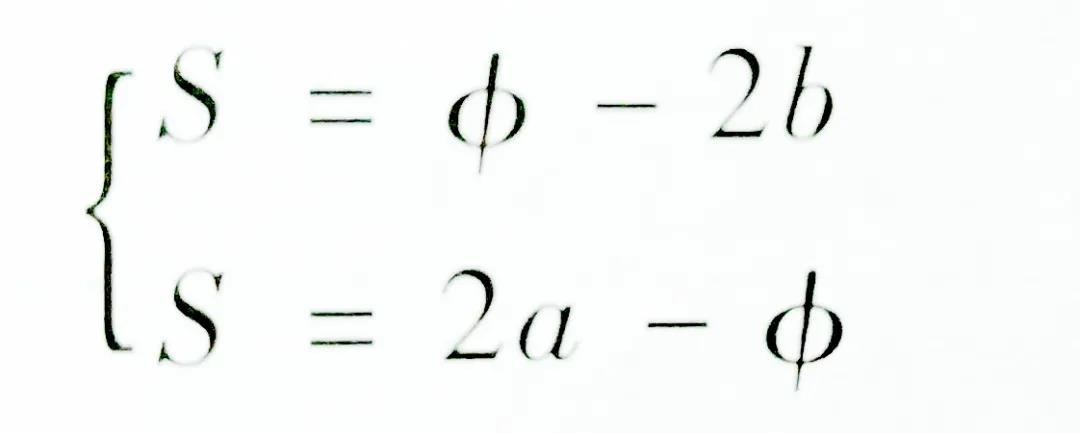

A: The edges of the billet are forced to be fully deformed. Comparing the black and red hole patterns in the figure, it is easy to see that when a thick-walled tube runs into a flat oval hole pattern, the first deformation is the edge and bottom of the tube blank. In the case of a circular closed hole, the distance is short S, and the horizontal is long S:

The combined solution of the two formulas can be S=△>0.

The result proves two points: first, the edge of the tube blank is the first to be deformed by the force in the flat oval pass, and the deformation force on the edge is the most direct, and the effect is the most significant; second, because the width of the flat oval pass is in the horizontal direction The upper part is larger than the round hole type, and there is a "△mm gap" between them, so there is no need to worry about the tube blank being massively reduced in diameter.

B: The deformed tube will spring back after it leaves the roll pass constraint, and the thick-walled tube will rebound more. Springback makes the deformation degree of the tube blank not up to people's expectations. Therefore, controlling and "eliminating" the springback has always been the goal pursued by our tube-making technicians. Analyzing the first formula, it can be seen that the size of the flat elliptical tube in the vertical direction is smaller than the diameter of the circular closed hole, so the difference between the two can be used to offset the springback of the tube after leaving the flat elliptical hole. In this way, compared with the round hole type tube blank after springback, the springback of the flat oval tube blank can be regarded as zero.

C: Improve roll sharing. By reducing the gap between the rollers in the figure, not only can the flat elliptical hole be further flattened; at the same time, the flat elliptical hole can be changed to an approximate round hole by increasing the roller gap, that is, the contour of the closed hole can be on a long axis. Change between an ellipse with a minor axis of (2a-roll gap) and a circle with a "diameter" of 2a. Then, the width range of the tube blank that can be formed by the flat elliptical closed-hole roll is: (2b-roll gap gap) π-bf ≤ B ≤2aπ-bf

It can be seen that this flat oval pass with multiple changes with the gap between the rolls realizes the sharing of rolls within a certain range.

(3) The design principle of the flat ellipse closed hole type:

A: Principle of equal perimeter. The error between the two is required to not exceed 1mm.

B:The principle of not much difference between the long and short axis. This is to ensure that the tube blank can become a basic cylindrical shape after leaving the flat elliptical closed hole shape and rebound. The first formula is a concrete manifestation of this principle.

C: The principle that the sum of the long and short semi-axes is equal to the diameter of the corresponding circular closed hole.

Comprehensive solution

The double-radius W hole at the edge of the rough forming section and the flat elliptical closed hole pattern of the fine forming section are comprehensively applied to a set of thick-walled pipe hole patterns, giving full play to their respective advantages in each forming stage, and jointly solving the thick-walled pipe forming blind zone and The difficulty of forming the rebound, the effect will be better. At the same time, the harm caused by the large difference between the inner and outer circumferences of the thick-walled pipe is also reduced.

For the directly forming to square pipe mill, four solutions are proposed for the forming difficulties of thick-walled pipes. According to the actual situation, the corresponding solutions are used to solve them. I hope to provide you with effective help.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province