Correct use of impedance device (magnetic rod) in welding of high frequency welded pipe equipment (2)

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-03 11:30

- Pvs:

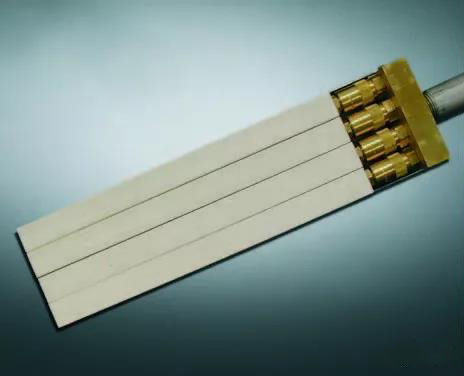

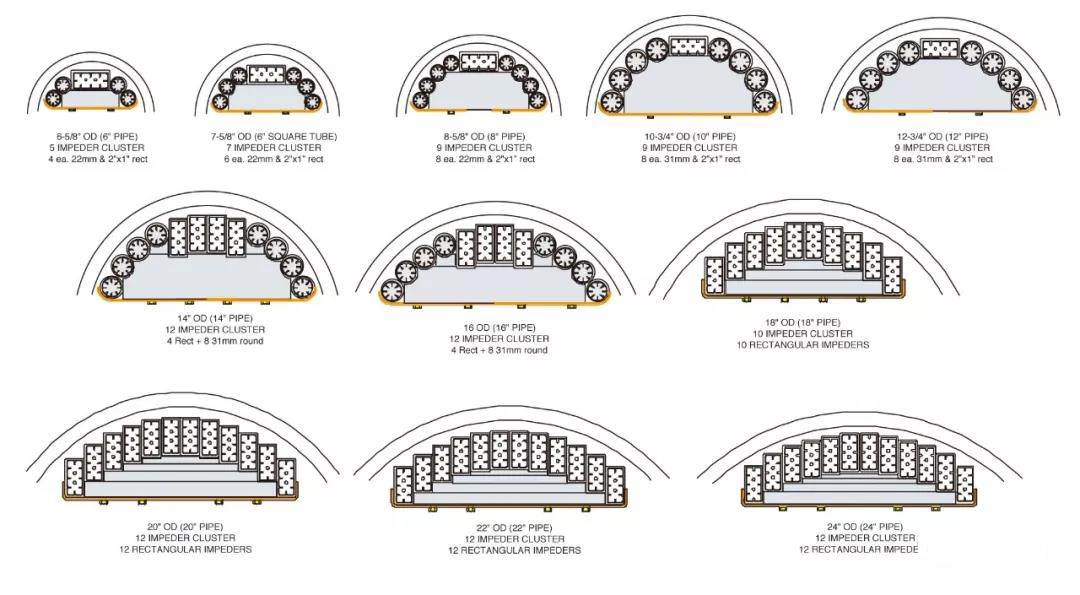

【概要描述】Usually the use of used high frequency welded pipe equipment consumes a lot of impedors device (magnetic rod). At the same time, when high-frequency induction welding technology is used to produce welded pipes, it is necessary to place impedors device (magnetic rod) in the inner cavity of the welded pipe blank to change the induced current in the pipe blank. Distribution, as shown in Figure 1. Placing the impedors device (magnetic rod) in a suitable position can cause the induced current to concentrate on the fusion surface of the welded pipe, thereby improving the efficiency of induction welding; if the placement of the resistor is not appropriate, it will not only reduce the welding efficiency of the welded pipe, but also Cause product quality problems.

Correct use of impedance device (magnetic rod) in welding of high frequency welded pipe equipment (2)

【概要描述】Usually the use of used high frequency welded pipe equipment consumes a lot of impedors device (magnetic rod). At the same time, when high-frequency induction welding technology is used to produce welded pipes, it is necessary to place impedors device (magnetic rod) in the inner cavity of the welded pipe blank to change the induced current in the pipe blank. Distribution, as shown in Figure 1. Placing the impedors device (magnetic rod) in a suitable position can cause the induced current to concentrate on the fusion surface of the welded pipe, thereby improving the efficiency of induction welding; if the placement of the resistor is not appropriate, it will not only reduce the welding efficiency of the welded pipe, but also Cause product quality problems.

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-03 11:30

- Pvs:

Usually the use of used high frequency welded pipe equipment consumes a lot of impedors device (magnetic rod). At the same time, when high-frequency induction welding technology is used to produce welded pipes, it is necessary to place impedors device (magnetic rod) in the inner cavity of the welded pipe blank to change the induced current in the pipe blank. Distribution, as shown in Figure 1. Placing the impedors device (magnetic rod) in a suitable position can cause the induced current to concentrate on the fusion surface of the welded pipe, thereby improving the efficiency of induction welding; if the placement of the resistor is not appropriate, it will not only reduce the welding efficiency of the welded pipe, but also Cause product quality problems.

Below we combine some experience in the production process to summarize the installation of the impedors device (magnetic rod) and the related issues that should be paid attention to in the production:

d. Several issues that should be paid attention to in the production process.

1) When installing the impedors device (magnetic rod), the front end should not exceed the center line of the squeeze roller too far, generally controlled between 3~6mm.

2) Do not touch the edge of the tube when adjusting the impedors device (magnetic rod), otherwise it will be easily carried away by the tube, and of course the distance should not be too large.

3) In the process of winding the impedors device (magnetic rod), care should be taken not to wind too thick or too thin. It should be appropriately determined according to the diameter, wall thickness and inner diameter of the steel pipe produced, and water cooling should be ensured in the middle. Clearance, and there are measures to prevent breakage.

4) During the production process, check the position of the impedors device (magnetic rod) and whether it is taken away or broken, and often remove the wire or debris hanging on the impedors device (magnetic rod).

5) In the normal production process, short magnetic bars can be attached to each side of the inductor, which can improve the welding efficiency (there are two functions:

① To strengthen the proximity effect of the lower tube blank edge of the inductor, reduce its eddy current loss, increase the welding current, and then improve the welding efficiency;

② To concentrate the induced current on the upper half of the tube blank, which can reduce the loss of the tube back).

6) In the case of a short magnet bar, part of the short magnet bar can be placed in the tube behind the magnet bar during adjustment to make up for the insufficient length of the short magnet bar.

7) In the normal production adjustment, attention should be paid to the cooling of the impedors device (magnetic rod) to reduce the use temperature of the internal magnetic rod and prolong its service life. If the high temperature exceeds the Curie temperature point (170~340°C), the magnetic rod will lose its magnetism, and the remaining effective magnetic rod will carry more magnetic flux density, which will further deteriorate the impedors device (magnetic rod) and eventually lead to The entire impedors device (magnetic rod) stops working.

In short, the impedors device (magnetic rod) is one of the main components of high-frequency welding (whether it is contact welding or induction welding). Whether the installation position is correct or not plays a key role in increasing the welding speed and improving the welding quality.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province