Key points of welding quality of used welded pipe machine (1)

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-02 11:30

- Pvs:

【概要描述】There are many factors that affect the welding quality of used welded pipe machine, and these factors interact and restrict each other in the same system.

Key points of welding quality of used welded pipe machine (1)

【概要描述】There are many factors that affect the welding quality of used welded pipe machine, and these factors interact and restrict each other in the same system.

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-02 11:30

- Pvs:

There are many factors that affect the welding quality of used welded pipe machine, and these factors interact and restrict each other in the same system.

When one factor changes, other factors will also change as it changes. Therefore, in the high frequency adjustment, it is not enough to pay attention to the local adjustment of the frequency, power, current or squeeze amount of the used welded pipe machine.

This adjustment must be based on the specific conditions of the entire molding system, comprehensively considered from all aspects related to high-frequency welding, and adjusted by excluding all influencing factors one by one.

Below we break down the main factors in the high-frequency welding process, there are the following eight aspects, we will introduce in detail ① frequency ② rendezvous angle (VEE angle)

① Frequency

This frequency refers to the high-frequency frequency of the used welded pipe machine during the welding process. The frequency during high-frequency welding has a great influence on the welding and quality, because the high-frequency frequency affects the distribution of current in the raw material.

The main influence of the selected frequency on welding is the size of the heat-affected zone of the weld.

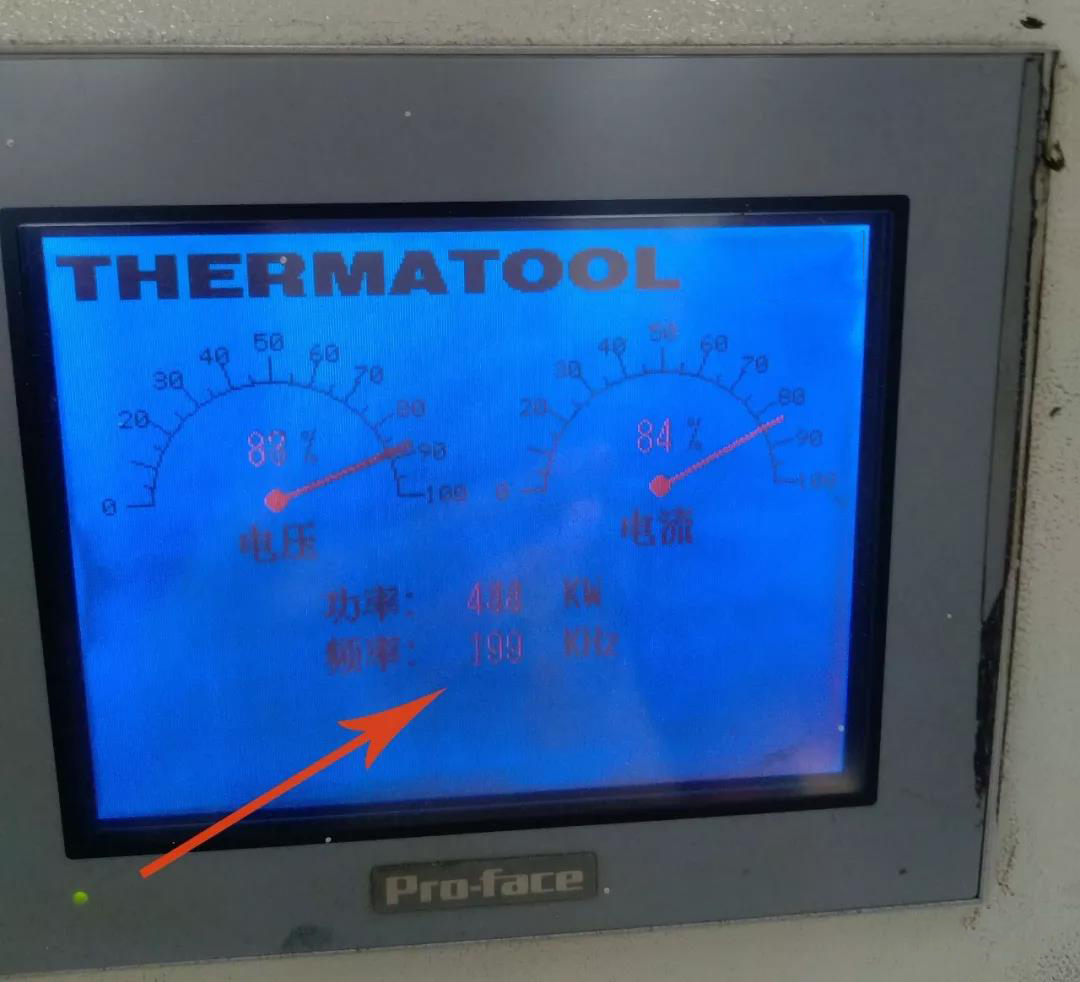

In terms of welding efficiency, a higher frequency should be used as much as possible. The high frequency current of 100KHz can penetrate 0.1mm of ferritic steel, while 400KHz can only penetrate 0.04mm, that is, the current density distribution on the surface of the steel plate, the latter is nearly 2.5 times higher than the former.

In production practice, the frequency of 300KHz~400Khz can generally be selected when welding ordinary carbon steel materials; while welding alloy materials or thick steel plates over 10mm, a relatively lower frequency can be used, because the chromium and zinc contained in alloy steel The skin effect of copper, aluminum and other elements is somewhat different from that of ordinary carbon steel. Metallography and metal composition are different, and the frequency required for welding is also different.

At present, foreign high-frequency manufacturers have adopted newer solid-state high-frequency technology. After setting a frequency range, it can automatically track and adjust the frequency according to the material thickness, unit speed and other conditions during welding.

The more high-end Chromatoer inverter welding machine can even gradually adjust the required optimal frequency in the frequency range, with an accuracy of adjustable to every 1KHz.

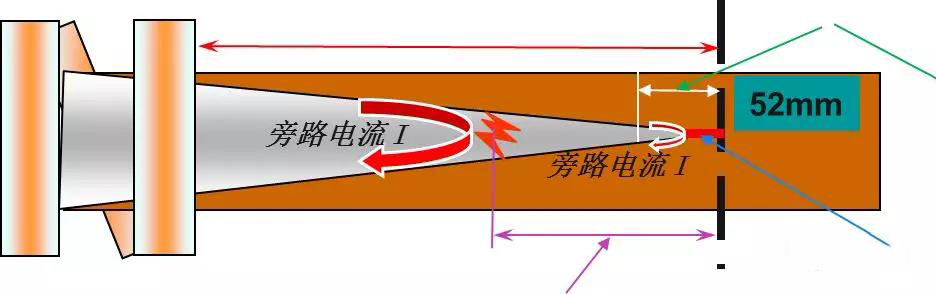

② Meeting angle (VEE angle)

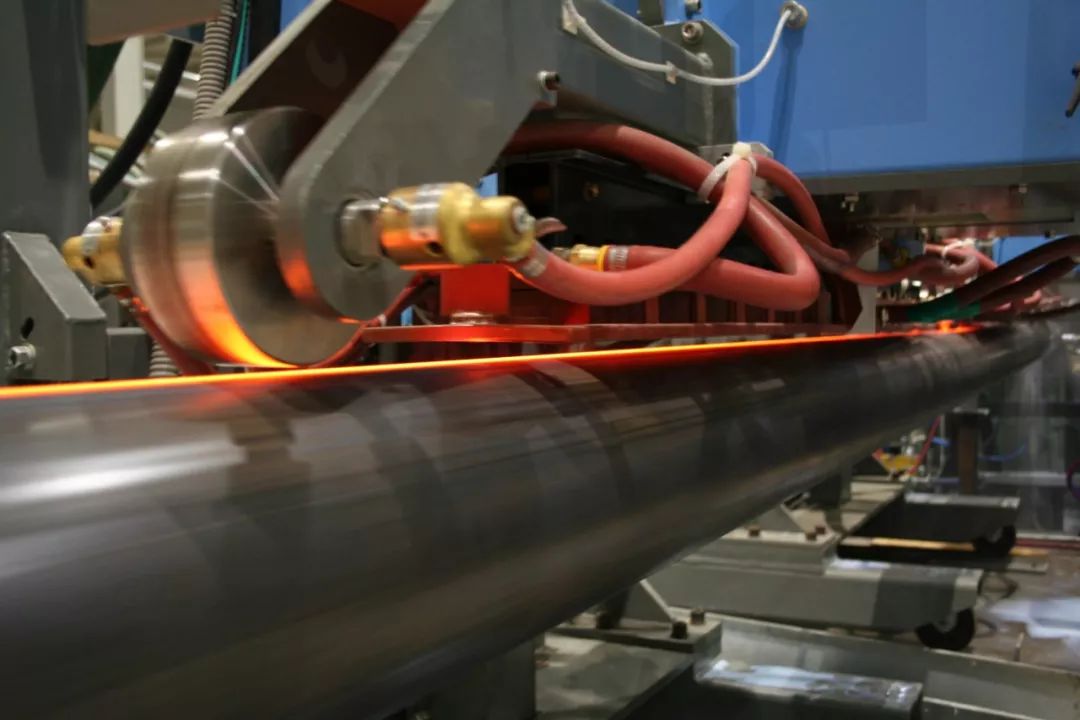

The meeting angle is the angle between the two sides of the strip when it enters the extrusion point. Due to the proximity effect, when the high-frequency current passes through the edge of the steel plate, the edge of the steel plate will form a preheating section and a melting section (also called a lintel). When the lintel section is heated violently, the molten steel inside is quickly vaporized and blasted It splashes out and forms a flash. This is the so-called "fire". The size of the meeting angle (VEE angle) has the most direct effect on the melting section (welding).

When the meeting angle is small, the proximity effect is significant, which is beneficial to increase the welding speed. However, if the meeting angle is too small, the preheating section and the melting section become longer, and the result of the longer melting section makes the flashing process unstable. After the lintel blasts, it is easy to form deep pits and pinholes, and it is difficult to squeeze and fuse.

When the meeting angle is too large, the melting section becomes shorter and the flash is stable, but the proximity effect is weakened, the welding efficiency is significantly reduced, and the power consumption increases.

In addition, when forming thin-walled welded pipes, the meeting angle will stretch the edges of the pipe and produce wavy wrinkles.

In the production of used welded pipe machine, we generally adjust the meeting angle within 2°-6°. The speed of the unit is faster when producing thin plates, and a smaller meeting angle is required for extrusion molding; the speed of the unit is slower when producing thick plates. Use a larger meeting angle when extruding.

Here is an empirical formula for reference: rendezvous angle * unit speed ≮ 100

Therefore, fully understanding the frequency and the angle of rendezvous (VEE angle) will affect the welding quality of the used welded pipe machine, so it is necessary to analyze other aspects of the welding quality of the used welded pipe machine to summarize the method and deal with it. Introduce ③welding method and ④input power. If necessary, you can continue to pay attention to us.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province