Common faults of used welded pipe mills production line forming machines (5)

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-22 11:30

- Pvs:

【概要描述】Common faults of used welded pipe mills production line forming machines can be divided into ① deviation ② scratches ③ "indenter" phenomenon ④ "drill belt" phenomenon. In order to let everyone understand the common faults of the molding machine in detail, we will introduce ③ "indenter" phenomenon.

Common faults of used welded pipe mills production line forming machines (5)

【概要描述】Common faults of used welded pipe mills production line forming machines can be divided into ① deviation ② scratches ③ "indenter" phenomenon ④ "drill belt" phenomenon. In order to let everyone understand the common faults of the molding machine in detail, we will introduce ③ "indenter" phenomenon.

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-22 11:30

- Pvs:

Common faults of used welded pipe mills production line forming machines can be divided into ① deviation ② scratches ③ "indenter" phenomenon ④ "drill belt" phenomenon. In order to let everyone understand the common faults of the molding machine in detail, we will introduce ③ "indenter" phenomenon.

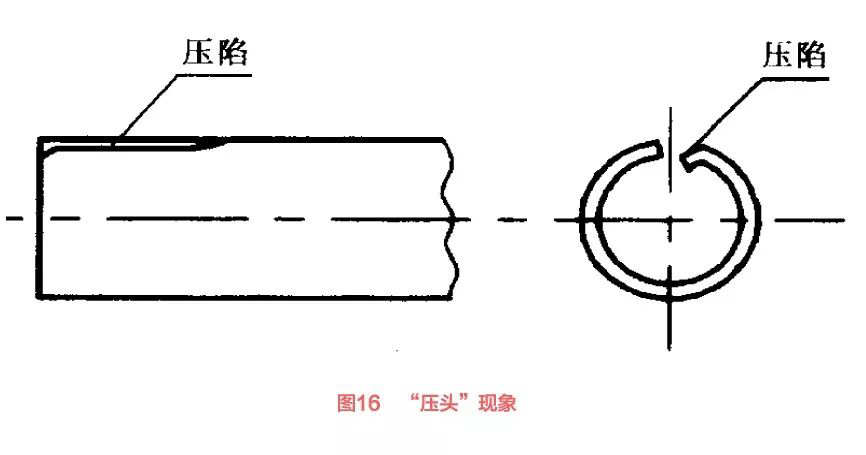

The phenomenon of "indenter" appears in the used welded pipe mills production line, which can be interpreted as "indenter" is actually a special manifestation of deviation, which generally occurs at the closed hole, and most of the tube blanks do not occur at the open hole. If it is overturned, one side edge of the tube blank is indented, and it mostly occurs when the tape is led. We call this phenomenon "indentation head" (Fig. 16).

There are two main reasons for "indenter":

① the shrinkage of the front vertical roller of the closed hole type is too large, or the center position of the vertical roller is not correct;

② the center of the closed pass and its front flat roll pass is not correct, or the pressure is insufficient, so that the tube blank floats back and forth during operation. Therefore, when leading the tape, pay attention to the specific performance of the head of the tube blank to find out the reason, and then deal with it in a timely manner. The edge indentation that occurs in the normal operation of the tube blank will be described in the welding seam accident.

The reason for the "indenter" phenomenon in the common failure of the forming machine of the used welded pipe mills production line is mainly because ①The shrinkage of the front vertical roller of the closed hole type is too large, or the center position of the vertical roller is not correct. ②The center position of the closed pass and its front flat roll pass is not correct, or the pressure is insufficient, so that the tube blank swings back and forth during operation.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province