Adjust the forming method of the thin-walled tube of the used roll forming machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-06-30 11:30

- Pvs:

【概要描述】The thin-walled tube forming adjustment of the used roll forming machine should not be limited to the forming machine, but must have an overall view and a global view. Here, a concept of generalized forming adjustment is proposed. That is, the forming adjustment is not only the adjustment of the forming machine, but also involves the welding machine, the sizing machine, the material storage (looper), the raw material, etc., which are closely related to the forming quality of the thin-walled tube.

Adjust the forming method of the thin-walled tube of the used roll forming machine

【概要描述】The thin-walled tube forming adjustment of the used roll forming machine should not be limited to the forming machine, but must have an overall view and a global view. Here, a concept of generalized forming adjustment is proposed. That is, the forming adjustment is not only the adjustment of the forming machine, but also involves the welding machine, the sizing machine, the material storage (looper), the raw material, etc., which are closely related to the forming quality of the thin-walled tube.

- Sort:Information

- Auth:

- Source:

- Release time:2022-06-30 11:30

- Pvs:

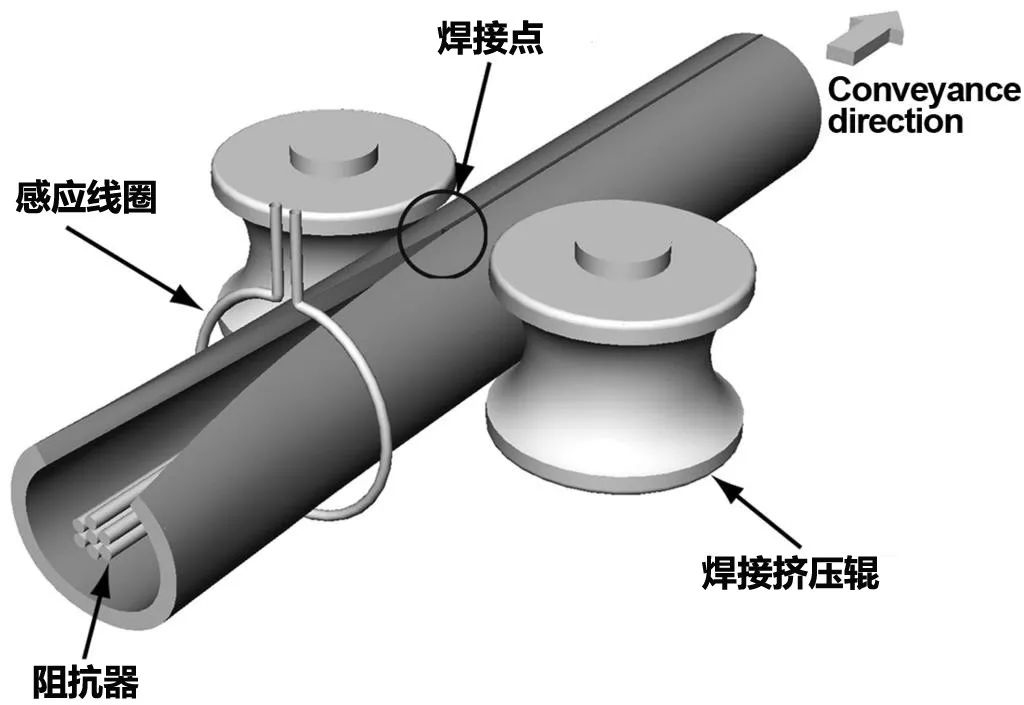

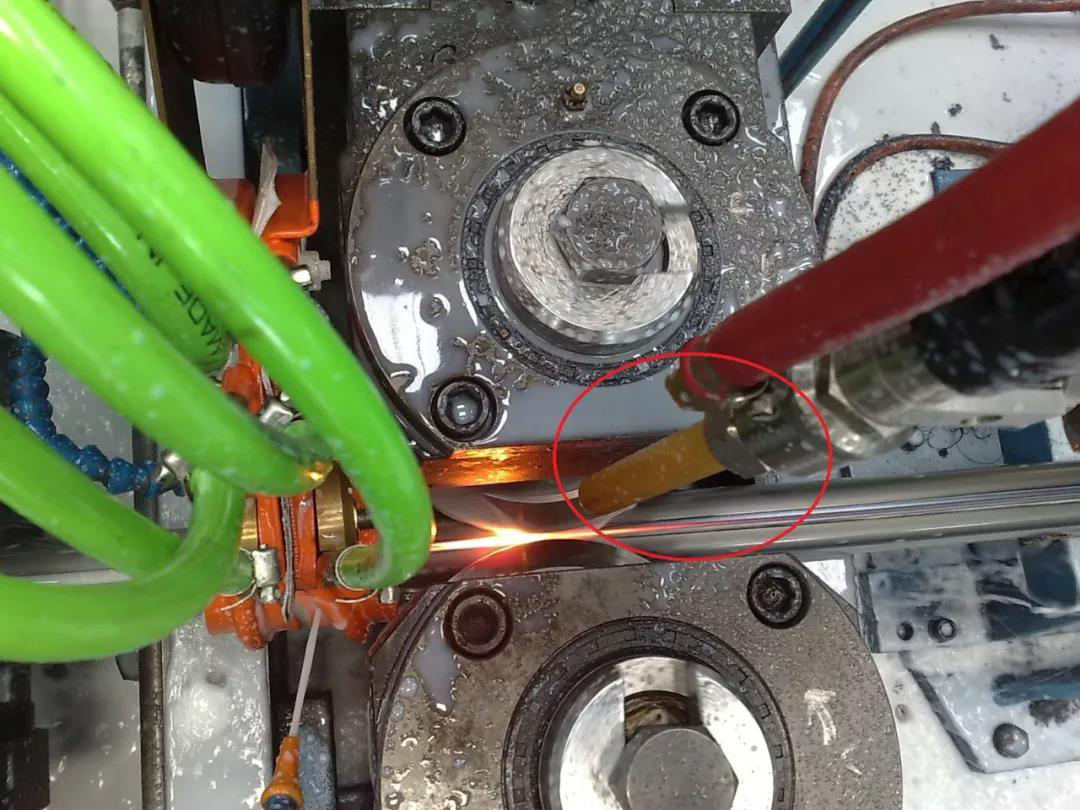

The thin-walled tube forming adjustment of the used roll forming machine should not be limited to the forming machine, but must have an overall view and a global view. Here, a concept of generalized forming adjustment is proposed. That is, the forming adjustment is not only the adjustment of the forming machine, but also involves the welding machine, the sizing machine, the material storage (looper), the raw material, etc., which are closely related to the forming quality of the thin-walled tube.

Thin-walled tube blanks

When the used roll forming machine manufactures thin-walled tubes, the tube blanks will be selected from the plate shape, performance, and thickness tolerances.

(1)Plate type. Due to cold rolling, slitting, bundling, hoisting, transportation and other reasons, the tube blank is prone to defects such as sickle bend, S bend, tower coil, lotus leaf edge, etc. After this kind of tube blank is unfolded, the two sides of itself are not equal in length. The part that grows out is generally difficult to eliminate and absorb by molding. In production practice, there have been many adjustment incidents caused by materials. For example, the adjustment workers have been operating as fiercely as tigers, but they have not been effective. Looking back, I found that it was the materials that were responsible. After replacing the materials, all the problems were solved.

(2)Performance. For thin-walled pipe materials, within the allowable range of welded pipe quality, appropriately increasing the strength and hardness of the pipe blank can improve the resistance of the edge of the thin-walled pipe blank to longitudinal plastic extension deformation and longitudinal instability, thereby preventing bulging.

(3) Thickness tolerance. The thicker the thickness of the tube blank, the greater the difficulty of longitudinal extension and deformation, the stronger the ability to resist lateral instability, and the more conducive to the forming of thin-walled tubes. Compared with the thin 0.05mm, the adjustment difficulty is completely different.

Operation adjustment

Thin-walled tube forming and hole type adjustment are restricted by the existing hole type, unit and materials, which make the adjustment methods and adjustment methods very limited.

(1) Adjustment of the storage process. It must be ensured that the upper and lower rollers of the feeding roller are parallel to prevent the edge of the tube blank from being unilaterally calendered by the delivery roller into unequal lengths on both sides; the material in the storage cage should be moderate to prevent the edge of the tube blank from being stretched and deformed to form a bad shape.

(2) Leveling roller adjustment. Thin-walled tube blanks are easy to form transverse wrinkles, and it is difficult to completely eliminate them by leveling rollers. After the corrugated tube blank enters the forming machine, it is equivalent to a small bulge with bright or dark edges. At the later stage of forming, these small bulges and recessive bulges can easily develop into dominant large bulges. Therefore, the reduction amount of the leveling roller should be appropriately increased to ensure that the thin tube blank entering the forming machine is basically wrinkle-free.

(3) Strengthen the control of the rolling bottom line and the rolling center line position of the forming roller to avoid the deviation of up and down and left and right.

(4) Longitudinal tension control. The longitudinal tension control of the thin-walled tube blank is reflected in two aspects: one is the longitudinal tension formed by the incremental bottom diameter of the roll, and the tension of the i+1 lane to be ensured is slightly larger than that of the i lane; the second is the adjustment of the whole machine To achieve sizing and pulling and forming, ensure that the thin-walled tube blank has sufficient longitudinal tension in the forming section.

(5) Increase the reduction amount of the upper roller of the closed hole type. It has at least three functions: 1. Increase the longitudinal tensile stress of the formed tube blank; 2. Enhance the roundness of the edge of the tube blank, thereby enhancing the rigidity of the edge of the tube blank and inhibiting the formation of bulging; 3. Enlarging the radial control of the hole pattern on the edge of the tube blank force to prevent bulging. At the same time, the closed-hole vertical roller can be appropriately lowered to improve the control ability of the upper part of the vertical roller's hole on the edge of the tube blank.

(6) Select the appropriate molding bottom line. The rolling bottom lines that are more suitable for thin-walled tube forming include uphill forming bottom line, downhill-upward convex arc composite forming bottom line, and double-radius forming bottom line.

According to the above methods, effectively adjust the thin-walled tube forming problem of the used roll forming machine to ensure the standard of welded tube forming in the production process.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province