Joint commissioning of forming section of pipe welder machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-05-20 11:30

- Pvs:

【概要描述】After the roll pass and tube blank of the pipe welder machine are adjusted one by one, it cannot be said that the forming is adjusted; it can only be said that adjusting each pass and tube blank is a prerequisite for a good forming, but not Necessary and sufficient conditions. Welded pipe adjustment requires the overall concept, overall concept and system concept, and organic integration of local adjustment and overall adjustment.

Joint commissioning of forming section of pipe welder machine

【概要描述】After the roll pass and tube blank of the pipe welder machine are adjusted one by one, it cannot be said that the forming is adjusted; it can only be said that adjusting each pass and tube blank is a prerequisite for a good forming, but not Necessary and sufficient conditions. Welded pipe adjustment requires the overall concept, overall concept and system concept, and organic integration of local adjustment and overall adjustment.

- Sort:Information

- Auth:

- Source:

- Release time:2022-05-20 11:30

- Pvs:

After the roll pass and tube blank of the pipe welder machine are adjusted one by one, it cannot be said that the forming is adjusted; it can only be said that adjusting each pass and tube blank is a prerequisite for a good forming, but not Necessary and sufficient conditions. Welded pipe adjustment requires the overall concept, overall concept and system concept, and organic integration of local adjustment and overall adjustment.

(1) Coordination of deformation amount between passes. By observing the opening size and naturalness of the edge of the tube blank between the front and rear passes, the individual rolls are fine-tuned to make the deformed tube blank look natural and smooth without sudden changes.

(2) The bottom line is neat and consistent. Through the fine-tuning of individual rolls, the actual height of the forming flat and vertical rolls is consistent with the forming bottom line, and there is no obvious fluctuation.

(3) Care for the surface quality of the tube blank. In particular, the slight pressure injury, indentation, dark line, etc. on the bottom and inner side of the deformed tube blank should be solved through the overall coordination adjustment, and the ones that cannot be eliminated should be reduced as much as possible.

(4) Balance of the load of the forming unit. Observing and judging the reduction amount of the flat roll and the shrinkage of the vertical roll, the traces on the tube blank can be observed by the reversing method, and the judgment and fine-tuning can be made based on the operating experience to eliminate the obvious streaks on the tube blank in individual passes. machine load. In addition, it is also necessary to observe the pipe welder machine and pay attention to the deformation of the vertical roller, so as to truly make the main deformation of the flat roller, prevent the vertical roller from "dominating the guest", and ensure that the tension between each section of the forming meets the requirements of the formula:

f1~2 <f2~3 <f3~4 <f4~5 <f5~6 <f6~7 <f welding section <f sizing section

This formula is the basic guarantee to ensure the smooth operation of the formed tube blank.

Basic standards for deformed tube blanks

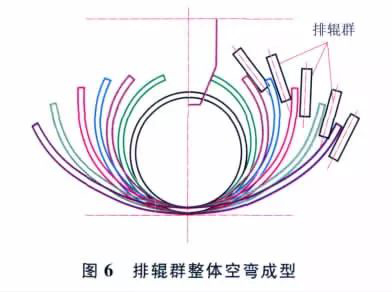

The flat tube blank is deformed into an open cylindrical tube after being rolled by more than ten specific pass rolls. The degree of deformation and quality of the tube have a profound impact on the subsequent high-frequency welding, sizing and finishing and the quality of the finished product. Therefore, it is necessary to evaluate the advantages and disadvantages of the tube to be welded that has been deformed. There are 8 basic standards:

(1) The geometric shape presents a basic symmetrical cylindrical shape. It feels smooth, fully deformed, symmetrical and regular.

(2) The geometric dimensions basically meet the design requirements. There is a small difference in "diameter" around the cylinder.

(3) The two sides of the edge are basically the same height.

(4) The open tube is not twisted, and the tube blank runs stably without shaking or setback.

(5) No waves and bulges on the edge, which is the most important criterion to measure the forming of thin-walled tubes.

(6) The deformation of the cross section is uniform.

① Ensure that the thinning and thickening of the wall thickness is not greater than 1/2 of the deviation of the pipe wall;

② Ensure that there is no trace of mutation in the cross section, because the plasticity of the mutation part of the pipe becomes poor, and it is easy to damage from the mutation part during subsequent pipe bending and expansion.

(7) Small rebound. Excessive springback indicates that the formed tube blank has insufficient deformation and large internal stress, and may automatically explode, bend and crack, and expand the tube after welding.

(8) There is no obvious crush, scratch, indentation, roll mark, dislocation and other marks on the surface. The just-adjusted forming unit is allowed to have slight surface defects for structural pipes and fluid pipes; but not for high-precision automobile pipes and furniture pipes.

Therefore, in addition to adjusting the roll pass and tube blank, it is also necessary to observe the pipe welder machine and pay attention to the deformation of the vertical roll to ensure that the forming effect of the welded pipe can meet the standard.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province