Understand the causes and solutions of welding seam dislocation of used welded pipe machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-22 11:30

- Pvs:

【概要描述】In the process of making used welded pipe machine, it is judged whether the quality of the welded pipe meets the standard. In addition to looking at the quality of the welded pipe, there is also the quality of the welded section. There are many types of quality defects in the welding section, and the dislocation of the weld is a common one.

Understand the causes and solutions of welding seam dislocation of used welded pipe machine

【概要描述】In the process of making used welded pipe machine, it is judged whether the quality of the welded pipe meets the standard. In addition to looking at the quality of the welded pipe, there is also the quality of the welded section. There are many types of quality defects in the welding section, and the dislocation of the weld is a common one.

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-22 11:30

- Pvs:

In the process of making used welded pipe machine, it is judged whether the quality of the welded pipe meets the standard. In addition to looking at the quality of the welded pipe, there is also the quality of the welded section. There are many types of quality defects in the welding section, and the dislocation of the weld is a common one.

Weld misalignment:

When the used welded pipe machine is used to make pipes, when the two butt welding surfaces of the tube blank are not on the same plane, the weld formed by welding at this time is a dislocation weld. Dislocation welds can be divided into three types: tendency dislocation, occasional dislocation and periodic dislocation. However, these three types of weld dislocation have a common defect feature, that is, after the external burr is normally removed, there is still an external burr on one side of the weld.

Due to the small welding area of the weld seam dislocation, the strength of the weld seam is seriously reduced, and the surface quality of the welded pipe is not high even if the weld seam surface is slippery.

There are many reasons for weld dislocation, which can be roughly divided into:

(1) The pressing down on both sides of the first and second flat rolls is asymmetric;

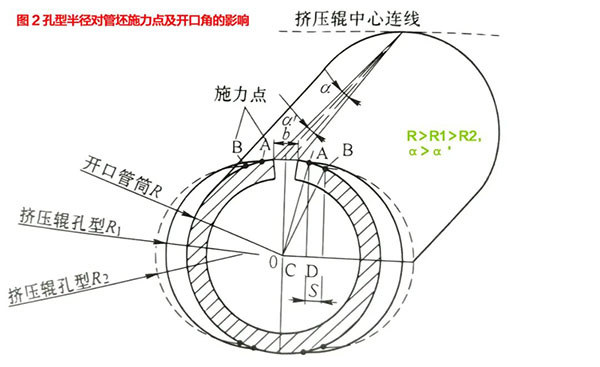

(2) There are reasons such as asymmetry, beating, and non-centering of the extrusion roller, closed-hole roller or guide roller;

(3) The forming flat roller bearing, vertical roller bearing, guide roller bearing and extrusion roller bearing are damaged;

(4) Thickness of tube blank, large width and narrow tolerance, strip S bend, sickle bend, etc.;

(5) The operation of the tube blank is unstable, and the left and right swings are large;

(6) There is an invisible bulge in the formed tube blank;

(7) The squeeze roll and guide roll deviate from the rolling center line seriously.

The above reasons affect each other. During the investigation, we can eliminate them one by one in the used welded pipe machine and take corresponding treatment measures according to the principle of first easy and then difficult, from explicit to invisible.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province