The mechanism and solution of flattening and cracking of welding seam during pipe making by used welded pipe machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-21 11:30

- Pvs:

【概要描述】In the process of making used welded pipe machine, welds will appear in welded pipes. In the process of manufacturing this welded pipe, the weld will experience the mechanism of flattening and cracking. At this time, we need to solve the mechanism of flattening and cracking of the weld.

The mechanism and solution of flattening and cracking of welding seam during pipe making by used welded pipe machine

【概要描述】In the process of making used welded pipe machine, welds will appear in welded pipes. In the process of manufacturing this welded pipe, the weld will experience the mechanism of flattening and cracking. At this time, we need to solve the mechanism of flattening and cracking of the weld.

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-21 11:30

- Pvs:

In the process of making used welded pipe machine, welds will appear in welded pipes. In the process of manufacturing this welded pipe, the weld will experience the mechanism of flattening and cracking. At this time, we need to solve the mechanism of flattening and cracking of the weld.

When the used welded pipe machine does the flattening test, the weld crack is divided into two types: positive flattening cracking and measuring flattening cracking.

(1) Positive pressure weld cracking:

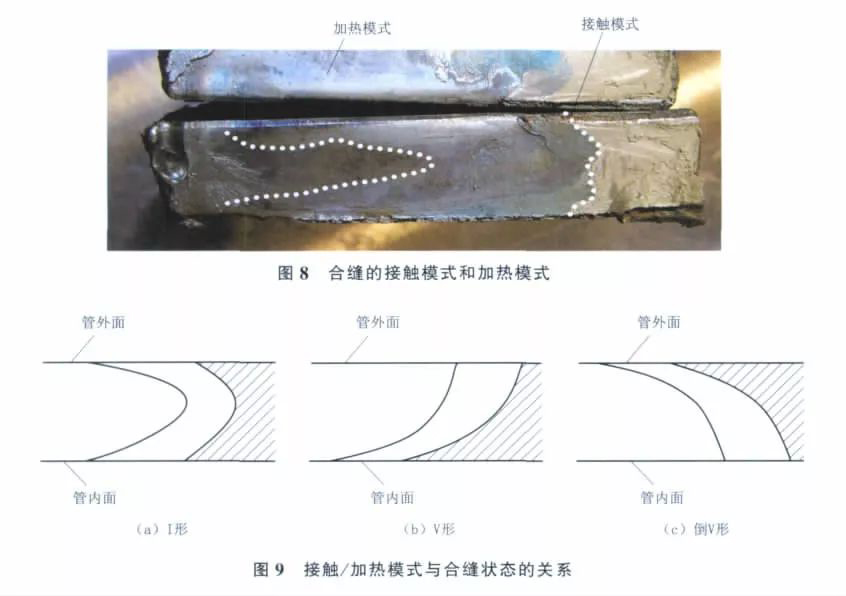

It refers to the flattening and cracking of the weld position and the force application direction on the same line. The mechanism of positive pressure internal cracking of thick-walled pipes is: when the positive pressure is applied, the outer circular weld of the welded pipe is compressed, the inner circular weld is stretched, and the inner side of the weld is easily cracked. The main reasons are: excessive deformation of the edge of the tube blank, and the welding seam is ∧-shaped butt; the extrusion force is too small; the welding heat is insufficient; the tube blank is hard, and the weld seam is easy to crack after being stressed.

The main measures to eliminate the internal cracking of the positive pressure weld of the thick-walled pipe made by the used welded pipe machine are: appropriately relax the first forming flat roll (W pass, edge deformation pass and comprehensive deformation pass) and closed-hole roll, and add at the same time. Large extrusion force, increase welding heat, and remove tube blanks with excessive hardness.

(2) Cracking of side pressure weld:

It refers to the complete cracking, partial cracking or cracking of the welding seam when the direction of the flattening force is 90° to the welding seam. The cracking mechanism of the lateral pressure weld is just the opposite of that of the positive pressure. When the lateral pressure is applied, the outer layer of the weld is in a stretched state, and the more the pressure is pressed, the smaller the curvature radius of the weld position, and the greater the tensile stress of the outer layer of the weld, the more It is easy to tear the weld and cause lateral pressure cracking.

The main measures to eliminate the lateral pressure cracking in the pipe making of used welded pipe machine are: increase the extrusion force and increase the welding heat; improve the forming quality, and strive to realize the parallel butt joint of the welding seam.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province