Used EWR tube mills, the influence of operations on welding quality in the production of welded pipes (2)

- Sort:Information

- Auth:

- Source:

- Release time:2021-12-20 11:30

- Pvs:

【概要描述】In the production process of used EWR tube mills welded pipe, there are many factors that will affect the final product quality of the welded pipe.

Used EWR tube mills, the influence of operations on welding quality in the production of welded pipes (2)

【概要描述】In the production process of used EWR tube mills welded pipe, there are many factors that will affect the final product quality of the welded pipe.

- Sort:Information

- Auth:

- Source:

- Release time:2021-12-20 11:30

- Pvs:

In the production process of used EWR tube mills welded pipe, there are many factors that will affect the final product quality of the welded pipe.

There are 7 factors that affect the welding quality of the welded pipe production operation of the used EWR tube mills. They are ① input heat (ie power KW) ② welding pressure (extrusion force) ③ welding speed (unit speed) ④ opening angle (Vee angle) ⑤ The placement position of the inductor (coil) and resistor ⑥ The geometric size and shape of the tube blank ⑦ The strip edge quality. the following first introduces the reasons ⑤ ~ ⑦ affecting the welding quality.

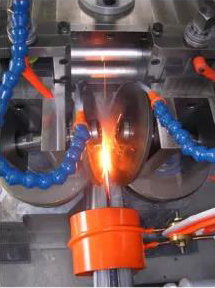

⑤The placement position of the inductor (coil) and impedance

The placement of the sensor (the distance from the center line of the squeeze roll) has a great influence on the welding quality. When it is far from the center line of the squeeze roller, the effective heating time is long and the heat-affected zone is wide, which reduces the strength of the weld; on the contrary, insufficient edge heating also reduces the strength of the weld. The sensor should be placed concentrically on the tube, and the distance between its front end and the center line of the squeeze roller is approximately equal to or less than the tube diameter (small tube is 1.5 times the tube diameter) for the best condition.

The placement position of the impedance device (magnetic bar) not only has a great influence on the welding speed, but also has an influence on the welding quality. Practice has proved that when the front end of the resistor is exactly at the center line of the squeeze roller, the flaring strength and flattening strength are the best. When it exceeds the center line of the squeeze roll and extends to the side of the sizing machine, the flaring strength and the bias strength are significantly reduced. When it is not on the center line but on the side of the molding machine, the welding strength is also reduced. The best position is that the resistor is placed in the tube blank below the inductor, and its head coincides with the center line of the squeeze roller or is adjusted 20~40mm in the forming direction, which can increase the resistance in the tube, reduce its circulating current loss, and increase the welding voltage. . When using a single-turn inductor, hang a small impedance on the left and right sides of the inductor, which not only increases the welding seam magnetic field, but also strengthens the edge proximity effect of the tube blank, and the welding speed can be increased by 4~5m per minute.

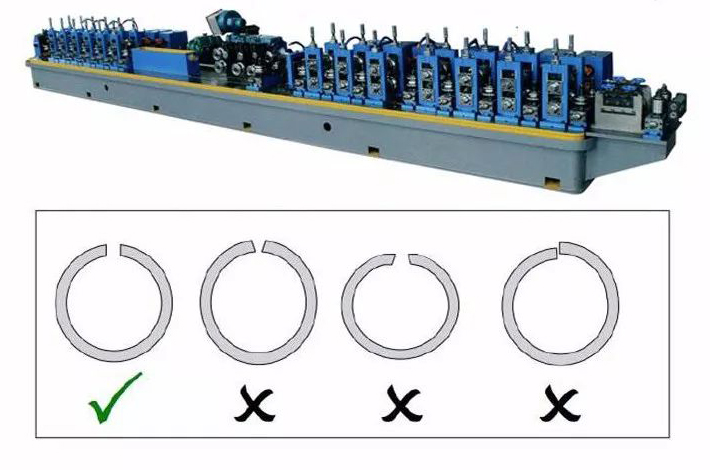

⑥Geometric size and shape requirements of the tube blank

The geometry of the welded tube

The large deviation of the width and thickness of the tube blank will change the heating temperature and extrusion amount of the edge. Qualified products must require the width and thickness of the tube blank to be within the tolerance range.

Tube shape and connection form

If there are phenomena such as deflection, sickle bend and wrinkle on the edge of the tube blank, it will deviate from the center of the hole when passing through the forming machine, causing the strip to bend on both sides. Poor roll adjustment can also cause defects such as strip deviation or tube billet distortion, which may affect welding quality or fail to weld at all.

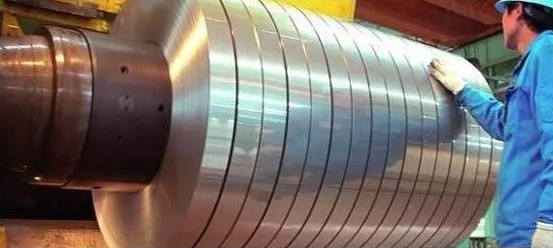

When the two ends of the tube blank are welded, the full thickness of the two ends must be connected, and the two edges of the tube blank must be not only straight but also parallel. Excessively large disc shear blade clearance or severe blade wear when slitting strip steel will cause excessive burrs on the edge of the strip steel, and it is also prone to cracks after welding.

⑦ Strip edge quality

The quality of the strip edge will affect the heating result of the high-frequency induction in the used EWR tube mills, thereby affecting the quality of the weld. After the tube blank is formed, it should be ensured that the two edges of the strip are parallel, otherwise the sharp corner effect will occur, which should never affect the quality of the weld.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province