The reason of the surface defect of the tube blank caused by the welding extrusion roller of the directly forming to square pipe mills

- Sort:Information

- Auth:

- Source:

- Release time:2022-11-06 11:30

- Pvs:

【概要描述】When directly forming to square pipe mills during operation and welding, the problem of the surface defect of the tube blank caused by the squeeze roller is often caused, and then the reason for the surface defect of the tube blank is caused.

The reason of the surface defect of the tube blank caused by the welding extrusion roller of the directly forming to square pipe mills

【概要描述】When directly forming to square pipe mills during operation and welding, the problem of the surface defect of the tube blank caused by the squeeze roller is often caused, and then the reason for the surface defect of the tube blank is caused.

- Sort:Information

- Auth:

- Source:

- Release time:2022-11-06 11:30

- Pvs:

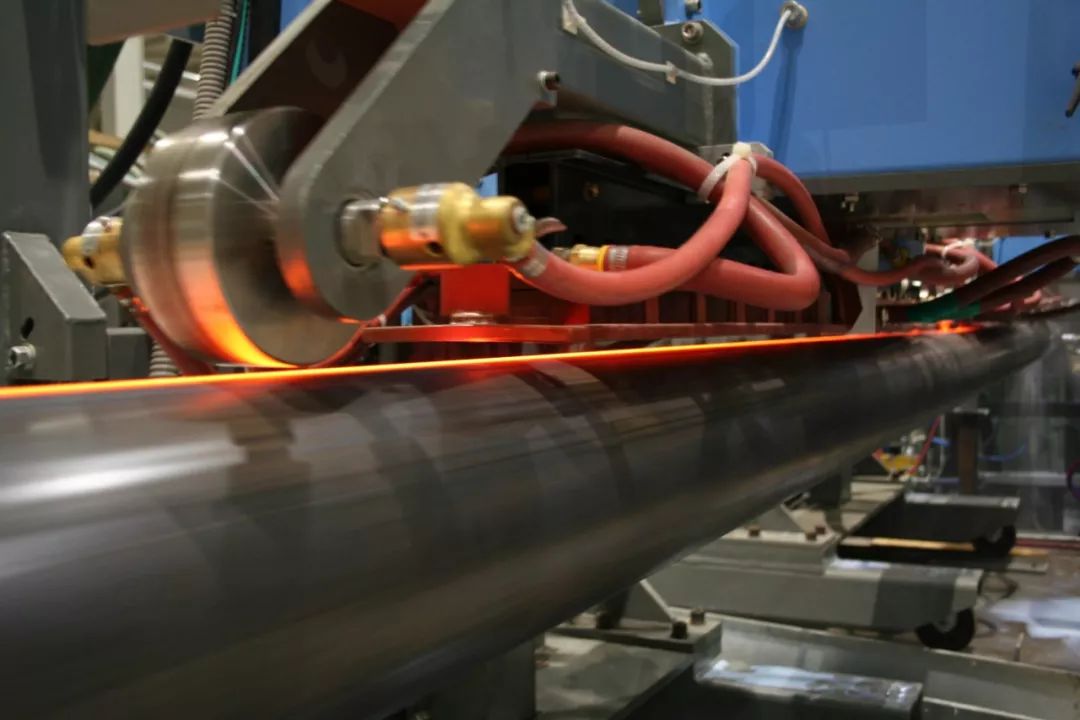

When directly forming to square pipe mills during operation and welding, the problem of the surface defect of the tube blank caused by the squeeze roller is often caused, and then the reason for the surface defect of the tube blank is caused.

The squeeze roll directly forming to square pipe mills causes the surface defects of the tube blank during welding. The main factor is the position and type of the defect, which can be divided into 6 types.

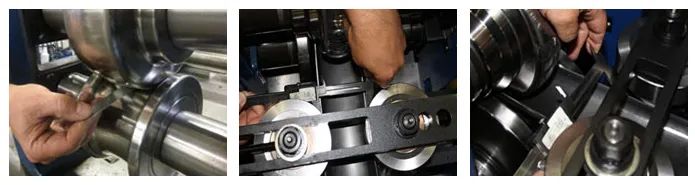

1. The inner roll edge of the upper squeeze roll causes linear indentation on the tube blank

Reasons: ①The upper squeeze roll is too large to press down, and the flat ellipse of the tube blank is larger than the vertical ellipse; ②The hole radius of the upper squeeze roll is too large.

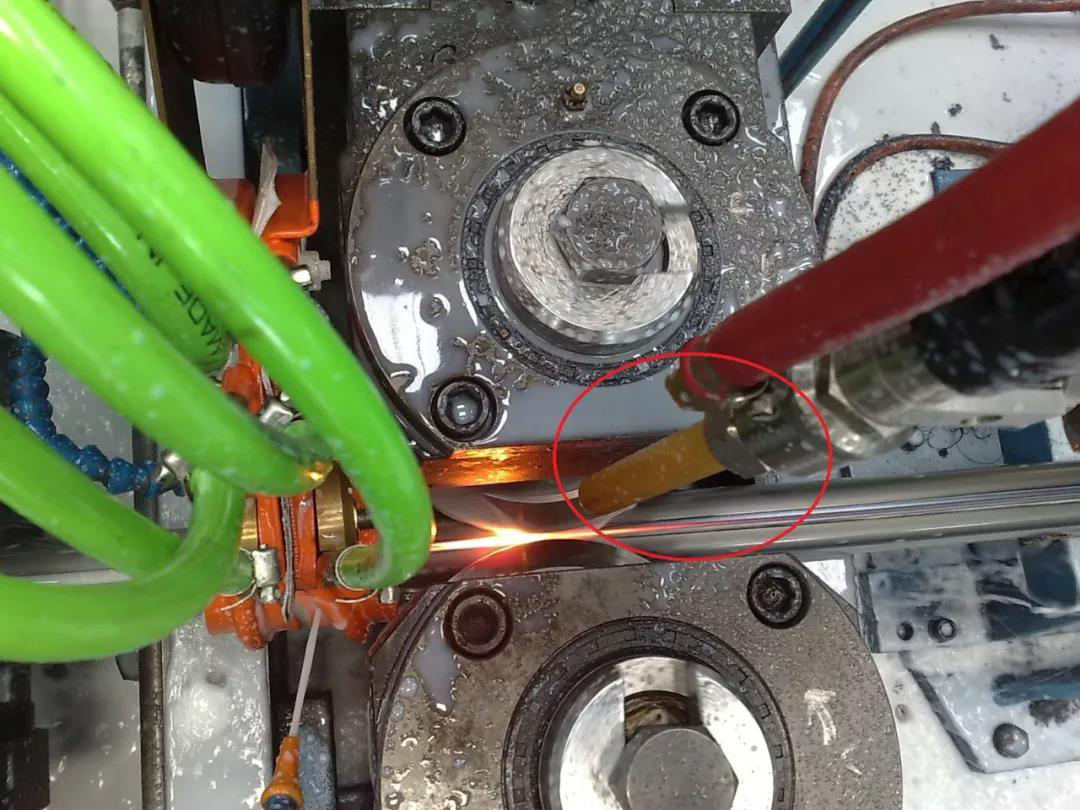

2. The inner roller edge of the upper squeeze roller presses the outer burr into the tube blank to form a pit

Reasons: ①The gap of the upper squeeze roller is too small; ②The center of the upper squeeze roller is offset; ③The crescent or bulge of the raw material is large and the forming is unstable.

3. The outer edge of the upper squeeze roller causes linear indentation on the tube blank

Reasons: ①The bearing of the upper squeeze roller is severely worn or damaged; ②The hole radius of the upper squeeze roller is too small; ③The flat ellipse of the tube blank is larger than the vertical ellipse; ④The center position of the upper squeeze roller is offset from the center of the unit.

4. The upper roll edge of the side squeeze roll causes linear indentation on the tube blank

Reasons: ①The side squeeze roller is low or inclined; ②The center of the side squeeze roller is offset from the center of the unit; ③The escape angle of the upper part of the side squeeze roller is too small; Larger than flat oval; ⑤The upper squeeze roller is insufficiently pressed.

5. The lower edge of the side squeeze roller causes linear indentation or crescent-shaped scratches on the tube blank

Reason: ①The side squeeze roller is too high; ②The center of the side squeeze roller is offset from the center of the unit; ③The escape angle of the bottom of the side squeeze roller is too small; Partially scratched.

6. The roll edge of the lower roll causes linear indentation on the tube blank

Reasons: ①The bottom roll is too high, the bottom roll is inclined or the side squeeze roll is too low; ②The center of the bottom roll is off the center of the unit; ③The escape angle of the bottom roll is too small; ④The side squeeze roll is insufficiently squeezed and the tube blank is larger Li oval.

After analyzing the main reasons for the indentation and scratches of the squeeze roller, it is found that any parameter is not isolated. The change of any parameter will affect other parameters, for example, in order to eliminate the upper edge of the side squeeze roller on the tube blank. Pressing the upper squeeze roller down due to the indentation will cause the welding squeeze force to increase, the squeeze amount becomes larger, and the butt joint shape changes. Therefore, after the indentation or scratch occurs when directly forming to square pipe mills, the cause should be carefully analyzed, and various effects must be comprehensively considered when processing. According to the above method, the squeeze roller of the unit is optimized and adjusted to eliminate the indentation and scratches caused by the squeeze roller to the tube blank, and the surface of the tube blank is smooth.

More News

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province