The factor causing the quality failure of the weld in the used welded pipe machine - periodic overlap welding

- Sort:Information

- Auth:

- Source:

- Release time:2023-08-06 11:30

- Pvs:

【概要描述】Factors that cause weld quality failures in used welded pipe machine include ①lap welding.②cycle lap welding. ③opening. ④bathholes. The following is an introduction to the cycle lap welding, the factor that causes the quality of the weld.

The factor causing the quality failure of the weld in the used welded pipe machine - periodic overlap welding

【概要描述】Factors that cause weld quality failures in used welded pipe machine include ①lap welding.②cycle lap welding. ③opening. ④bathholes. The following is an introduction to the cycle lap welding, the factor that causes the quality of the weld.

- Sort:Information

- Auth:

- Source:

- Release time:2023-08-06 11:30

- Pvs:

Factors that cause weld quality failures in used welded pipe machine include ①lap welding.②cycle lap welding. ③opening. ④bathholes. The following is an introduction to the cycle lap welding, the factor that causes the quality of the weld.

Lap welding is an intermittent appearance, sometimes not, sometimes the length of the lap welding is slightly longer, a few centimeters or even tens of centimeters, and sometimes it is slightly shorter, ranging from one to two centimeters or less. Sometimes lap welding occurs regularly and equidistantly, and sometimes it appears irregularly. For these lap welding phenomena, we collectively refer to them as periodic lap welding. Periodic lap welding in used welded pipe machine generally occurs in the middle and late stages of production, mainly due to the following reasons:

(1) The guide ring is broken. When the closed pass is worn, the normal operation of the tube blank cannot be effectively controlled, and the tube blank can swing back and forth in the pass. At this time, after the guide ring ruptures and there is a gap, the edge of the tube blank will be compressed by the gap of the guide ring during the running process, thereby forming the generation of lap welded pipe. The characteristics of this lap welded pipe are the same length of lap welding cycle, strong regularity, and easier to judge. Generally, as the guide ring rotates after the rupture, the traces of compression can be found.

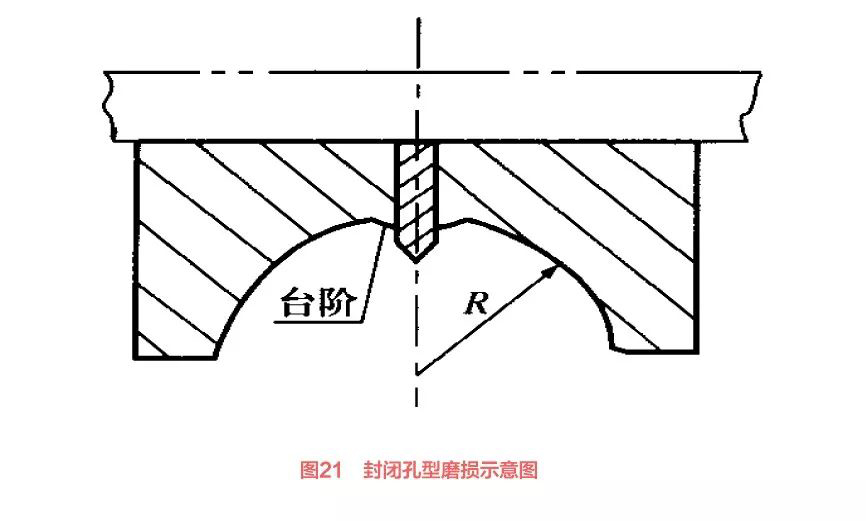

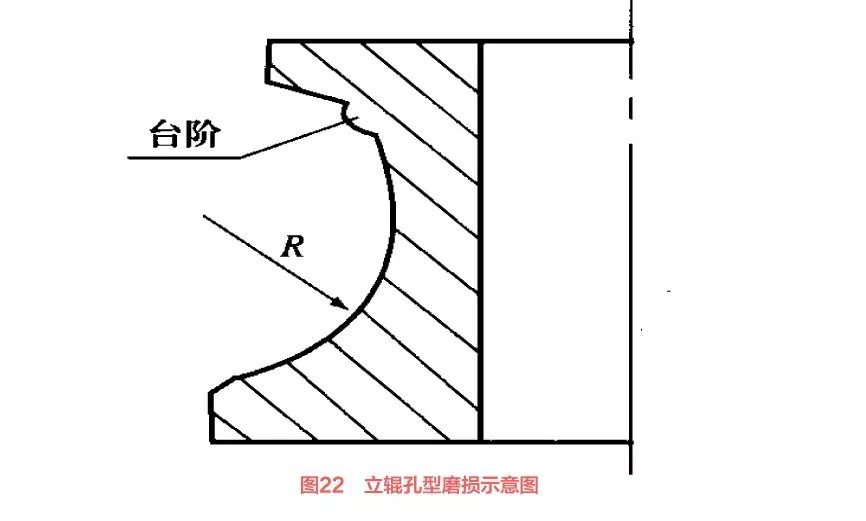

(2) Hole type wear. Mainly refers to the stepped shape at the bottom diameter of the upper roller of the closed hole type,and the stepped shape at the upper edge of the vertical roller hole type of the open hole type.

When the blank tube slides to the part of the hole-shaped boss when it swings in the hole pattern, the blank tube will be deformed. The edges produce sag marks to form lap welding. Sliding in and out instantly makes the lap welding smaller, and vice versa. The best way to eliminate this kind of overlap welded pipe is to make reasonable adjustments during normal production to make the hole wear uniform and avoid stepped shapes. Once the irregular shape of the arc of the hole is found, it must be replaced in time. In order to completely eliminate the occurrence of lap welding.

(3) Foreign matter on the arc surface of the hole. Sometimes on the arc surface of the pass, other metal foreign bodies are adhered for some reason, which will cause the surface of the tube blank to appear indentation scars. When the adhesion position of this foreign body is in the trajectory of the edge of the tube blank , It will cause short and equidistant periodic lap welding. Under normal circumstances, this phenomenon rarely occurs.

(4) Swing seam. In the later stage of production, the pass wear is more serious, the ability to control the tube blank is gradually reduced, and the center position of each pass has been damaged to varying degrees. Therefore, from forming to welding, the phenomenon of unsteady running of the tube will appear. The lap welding caused by the swing seam is mostly caused by the vertical roller. The flat roller sometimes causes some lap welded pipes, but the probability is smaller in comparison. When inspecting the edge condition of the tube blank, it is also difficult to find any abnormalities and obvious depression defects. The height of the two edges of the tube blank is slightly different until the squeeze roll. At this time, attention should be paid to the shape of the upper edge of the vertical roll pass. If it is ideal, the shrinkage of the vertical roll can be increased to obtain a perfect tube blank edge deformation effect. If the upper edge of the vertical roll pass is not too good In good times, it is necessary to reduce the shrinkage of the vertical roll to prevent undesirable deformation.

(5) The bearing is damaged. After the closed-hole bearing is damaged, the smooth running of the tube billet cannot be controlled well, and the phenomenon of wobble seam is prone to occur, and the possibility of lap welding will follow. Especially after the bearing with multiple closed holes is damaged, the lap welding problem will be more serious. Of course, this phenomenon rarely occurs even if it happens. Adjustment will not solve the problem.

Due to the above 5 factors, the quality of the welding seam in the used welded pipe machine is caused by periodic lap welding. When the welded pipe is made, it is necessary to check whether the used welded pipe machine has these problems.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province