Tension adjustment of sizing section of high frequency welded pipe equipment

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-27 11:30

- Pvs:

【概要描述】The process characteristics of the high frequency welded pipe equipment are: at the same time, the forming section, the welding section and the sizing section respectively perform continuous operations with completely different process connotations and process objectives for the same flexible welded pipe blank.

Tension adjustment of sizing section of high frequency welded pipe equipment

【概要描述】The process characteristics of the high frequency welded pipe equipment are: at the same time, the forming section, the welding section and the sizing section respectively perform continuous operations with completely different process connotations and process objectives for the same flexible welded pipe blank.

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-27 11:30

- Pvs:

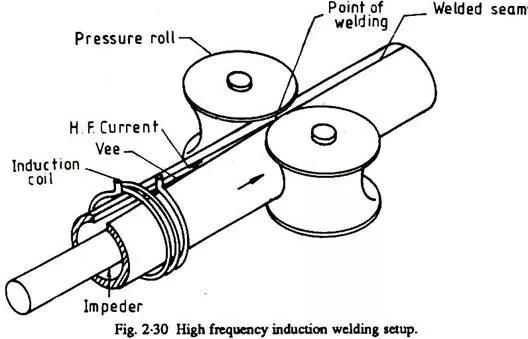

Tension coordination principle of sizing section

The process characteristics of the high frequency welded pipe equipment are: at the same time, the forming section, the welding section and the sizing section respectively perform continuous operations with completely different process connotations and process objectives for the same flexible welded pipe blank. In order to ensure the pipe blank In the forming section, welding section and sizing section, neither "pulling the tube" nor "pushing the tube" occurs. According to the rolling principle, it is necessary to ensure that the welded tube blank maintains proper tension in each section.

In addition to the pass speed and rolling force, the factors that affect the tension are the sizing allowance, the outer diameter of the welded pipe, the wall thickness, the deformation method (round, round, and different), and the raw materials of the tube blank (hot rolling, cold rolling, etc.). rolling, hard cooling, annealing, etc.), coolant, pass shape and surface roughness, etc. If the tension is too small, the welded pipe cannot run stably in the sizing roller, the welding seam sways from side to side, the tolerance size fluctuates greatly, the straightness changes frequently, and even causes "push pipe"; if the tension is too large, the hole pattern is easy to wear and even pull Broken strip steel joint.

Coordination of tension between sizing section and welding section

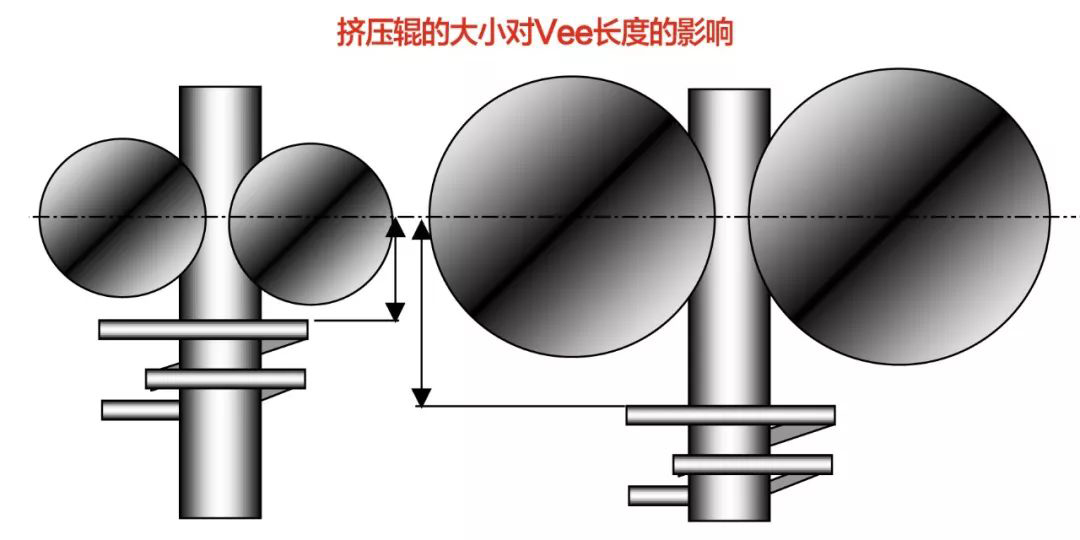

During the operation and welding of high frequency welded pipe equipment, the circumference of the welded pipe blank in the welding section is shortened after being squeezed by the extrusion roller, and some of them are converted into internal and external burrs, and some of them are converted into thickness increments. If the converted length is not absorbed in this section (especially for materials with high hardness), then the cumulative longitudinal growth will inevitably lead to the welded pipe under the combined action of the thrust of the forming section and the resistance of the sizing section Arching between the squeeze rolls prevented production from continuing. Therefore, it is necessary to maintain a certain tension in the sizing section to digest and absorb the length increment.

A method of adjusting the tension of the welding section. Corresponding adjustment measures can be taken according to the power supply method of high frequency welded pipe equipment.

(1) The unit with the same dragging + forming and sizing speed ratio

Control method 1: The tension factor is taken into account in the design of the roll, so that there is a reasonable difference between the bottom diameter of the first flat roll for sizing and the bottom diameter of the final flat roll for forming.

Control method 2: Appropriately increase the rolling force of the sizing flat roll, and at the same time appropriately reduce the rolling force of the sizing vertical roll, which actually increases the frictional force of the driving roll and forms the pulling of the welded pipe in the welded section, thereby increasing the Tension on welded pipe with large welded section.

Control method 3: Appropriately increase the extrusion force and the guide roller to press down, so that the resistance of the guide roller and the squeeze roller increases, which is equivalent to pulling the welded pipe in the forming direction and thus increasing the tension of the welding section. Control method 4: Appropriately reduce the pressure of the forming flat roll, and at the same time, the rolling force of the forming vertical roll can be appropriately increased, which is consistent with the principle of method three.

(2) Units with single drag + forming and different sizing speed ratios

In terms of controlling the longitudinal tension of the welding section, there is no essential difference between this unit and the previous unit. Because the speed ratio is constant, the bottom diameter of the forming flat roll and the bottom diameter of the sizing flat roll are actually fixed values, that is, the speeds of the forming section and the welding section are also fixed values, so you can refer to the tension control method of the above unit for reference.

(3) Double drag unit

The method of controlling the longitudinal tension of the welding section is to adjust the speed of the other motor relative to the fixed forming motor or the sizing motor to change the speed of the sizing machine or the forming machine, and the tension of the welding section changes accordingly.

Whole line tension control

Main line tension coordination of high frequency welded pipe equipment is the premise and guarantee for the smooth operation of the welded pipe unit. The adjustment of the whole line is usually carried out after a full roll change or a half roll change.

Appropriate standard for measuring sizing tension

(1) The welded pipe runs in a straight line in the cooling water tank without shaking and waves left and right.

(2) The position of the welding seam is basically fixed in the cooling section and the sizing machine, without torsion and left-right deflection.

(3) There is no wear tumor on the edge of the pass of the sizing flat roll. If the direction of the wear nodule is consistent with the rotation of the pass, at least it means that the sizing rolling force is too large, otherwise, it means that it is too small.

Randomly saw the welded pipe between the cooling section of the welded pipe and the sizing, and judge the longitudinal tension according to whether there is a feeling of "clamping the saw blade" during the sawing process.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province