Purpose of induction heating weld seam treatment of used round tube forming machines

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-23 11:30

- Pvs:

【概要描述】The service performance of the welded pipe is comprehensively evaluated by the performance of the two parts of the metal of the pipe body and the weld, and the weakest item of any one will determine the service performance of the welded pipe. During the welding process of the used round tube forming machines, due to the high temperature of welding, the metal structure of the weld and the heat-affected zone changes, the grains are coarsened, and there is also a large internal stress. Combining the results of these changes, the properties of the metal in the weld zone and the base metal (tube body) are very different. Moreover, the overall performance of the weld metal is significantly lower than that of the pipe body. For this reason, the difference must be eliminated by heat treatment of the weld, making it a "seamless welded pipe" with consistent comprehensive properties.

Purpose of induction heating weld seam treatment of used round tube forming machines

【概要描述】The service performance of the welded pipe is comprehensively evaluated by the performance of the two parts of the metal of the pipe body and the weld, and the weakest item of any one will determine the service performance of the welded pipe. During the welding process of the used round tube forming machines, due to the high temperature of welding, the metal structure of the weld and the heat-affected zone changes, the grains are coarsened, and there is also a large internal stress. Combining the results of these changes, the properties of the metal in the weld zone and the base metal (tube body) are very different. Moreover, the overall performance of the weld metal is significantly lower than that of the pipe body. For this reason, the difference must be eliminated by heat treatment of the weld, making it a "seamless welded pipe" with consistent comprehensive properties.

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-23 11:30

- Pvs:

The service performance of the welded pipe is comprehensively evaluated by the performance of the two parts of the metal of the pipe body and the weld, and the weakest item of any one will determine the service performance of the welded pipe. During the welding process of the used round tube forming machines, due to the high temperature of welding, the metal structure of the weld and the heat-affected zone changes, the grains are coarsened, and there is also a large internal stress. Combining the results of these changes, the properties of the metal in the weld zone and the base metal (tube body) are very different. Moreover, the overall performance of the weld metal is significantly lower than that of the pipe body. For this reason, the difference must be eliminated by heat treatment of the weld, making it a "seamless welded pipe" with consistent comprehensive properties.

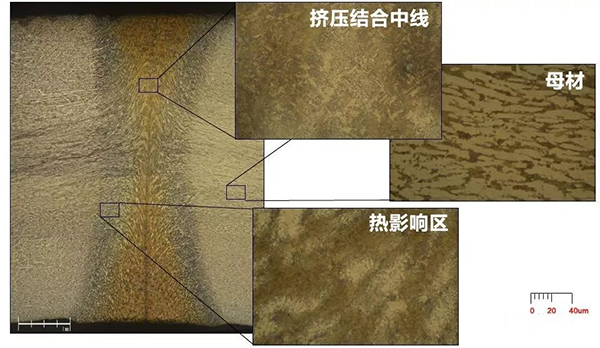

The figure below shows 3 different metallographic structures in the weld area (base metal, heat affected zone, centerline)

(1) Eliminate the internal stress generated by welding. The heat affected zone formed on both sides of the weld due to welding forms three areas with completely different structures, grain sizes and stress distributions from the weld and the pipe body. Due to the different heating temperatures and cooling rates of the weld, heat-affected zone and tube body, the internal stress inside is different. The internal stress in the weld is the largest, followed by the heat-affected zone and the smallest in the tube. When the internal stress exceeds the yield limit, the metal will be plastically deformed, causing the welded pipe to bend; when the internal stress exceeds the strength limit, grain boundary cracks will occur in the metal, and cracks will occur in the weld after the cracks expand. The metal grains in the weld zone are coarse, the yield strength and tensile strength are the lowest, and cracks are most likely to occur, followed by the heat-affected zone, which is also prone to cracks compared with the pipe body. Therefore, in order to improve the comprehensive performance of the weld, the used round tube forming machines must eliminate the internal stress of the welding through heat treatment. Usually normalizing or high temperature annealing treatment is used to eliminate internal stress in the weld.

(2) Improve the microstructure of the metal in the weld and heat-affected zone. Most of the steel strips used for pipe making are hot-rolled and air-cooled and normalized, with fine ferrite + pearlite structure; some microalloyed high-strength steel strips are small needle-like Ferrite structure. Under the action of high temperature welding, the used round tube forming machines brings two adverse consequences to the weld metal: ① the grains of the metal are coarsened, resulting in a decrease in yield strength and metal embrittlement; ② due to the uneven cooling speed after welding, In the weld zone, the cooling rate is slow, the ferrite and pearlite are coarse, and the heat-affected zone has a faster cooling rate. In addition to ferrite and pearlite, there are also coarse martensite and retained austenite. In summary, due to the grain coarsening and the change of metal microstructure, the weld metal is embrittled, and it is very different from the structure and properties of the pipe metal. Therefore, it is necessary to refine the grains and restore the metallographic structure through the heat treatment of the weld to reduce the difference with the tube body.

The chemical composition of steel used as welded pipe is shown in Table 1 below

Our company has many brands and wide resources, there is always one suitable for you. You only need to inform us of your pipe manufacturing needs, and our company will provide you with used welded pipe equipments that really suits your needs. Welcome new and old customers to come to consult and order.

More News

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province