How to quickly put into production when purchasing second-hand coiled and welded pipe equipment?

- Sort:Information

- Auth:

- Source:

- Release time:2021-04-09 11:30

- Pvs:

【概要描述】01. Selection of second-hand welded pipe equipment models To purchase second-hand coiled and welded pipe equipment, first do a good job of positioning the equipment selection. In which fields are th

How to quickly put into production when purchasing second-hand coiled and welded pipe equipment?

【概要描述】01. Selection of second-hand welded pipe equipment models

To purchase second-hand coiled and welded pipe equipment, first do a good job of positioning the equipment selection. In which fields are th

- Sort:Information

- Auth:

- Source:

- Release time:2021-04-09 11:30

- Pvs:

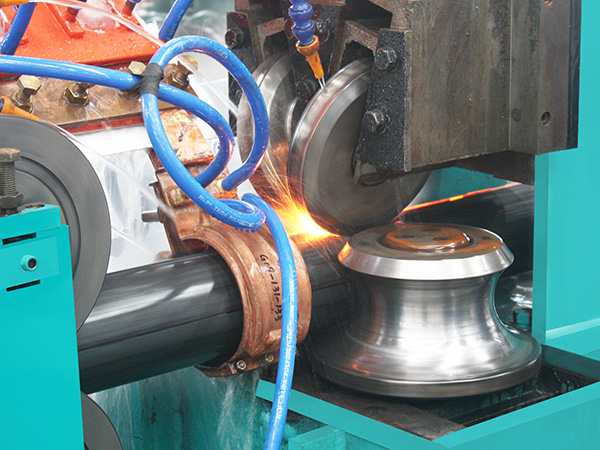

01. Selection of second-hand welded pipe equipment models

To purchase second-hand coiled and welded pipe equipment, first do a good job of positioning the equipment selection. In which fields are the steel pipes produced, what are the specific requirements for the outer diameter, thickness, and precision of the steel pipe, how many tons of production capacity is required, etc.; the product positioning is clear, and the equipment selection can be done well.

For example, the most popular rack tubes on the market, if the capacity requirements are not high, you can choose 50 heavy or ordinary 76 type second-hand coiled pipe welded pipe equipment, the speed is 60-90 m/min; if the capacity requirements are high, such as 3000 per month For more than ton, it is necessary to choose a high-speed type 76 or type 89 second-hand coiled pipe welded pipe unit with a speed of 90 m-120 m/min or more.

02.Plant and power planning for second-hand coiled and welded pipe equipment

When purchasing second-hand coiled pipe and welded pipe equipment, it is necessary to plan the production workshop and power matching. According to the equipment capacity and model requirements, rationally plan the plant and power. This step of planning has a relatively large impact on the later production capacity and production costs. It seems simple. In fact, it is very important. Plants and electricity that are too large will increase product costs, and too small will affect the output of production capacity.

What organization can provide professional selection of second-hand pipe coil and welded pipe equipment and plant power planning? Only institutions equipped with mechanical, electrical, and process engineers can provide professional services and recommend suitable second-hand pipe coil and welded pipe equipment models, as well as plant and power planning plans.

03.Installation and commissioning service of used coil and welded pipe equipment

The installation and commissioning service of second-hand coiled pipe and welded pipe equipment is another point that must be paid attention to when purchasing second-hand welded pipe equipment. Good equipment does not mean that products can be processed well. Good equipment can only be processed quickly through the empowerment of installation and commissioning engineers.

Sometimes there is not much difference between second-hand coiled pipe welding equipment and new welded pipe equipment. New equipment has installation and commissioning services. Because of the lack of professional installation and commissioning services, second-hand equipment has widened the gap with new equipment.

Professional installation and commissioning services can not only shorten the installation and commissioning time of equipment, speed up the rapid commissioning of second-hand coiled and welded pipe equipment, but also improve or optimize equipment performance to maximize the effectiveness of equipment. Good equipment also requires good service.

Many buyers of second-hand welded pipe equipment only pay attention to the equipment itself, ignoring the service of the equipment, so that the performance of the equipment is discounted. As everyone knows, new equipment + zero service ≤ second-hand equipment + good service, good product + good service = high cost performance.

Only with suitable second-hand pipe welding equipment, mature plant power planning scheme, and installation and commissioning services can the rapid commissioning of second-hand pipe welding equipment be ensured. So choosing the right organization is as important as choosing the right equipment.

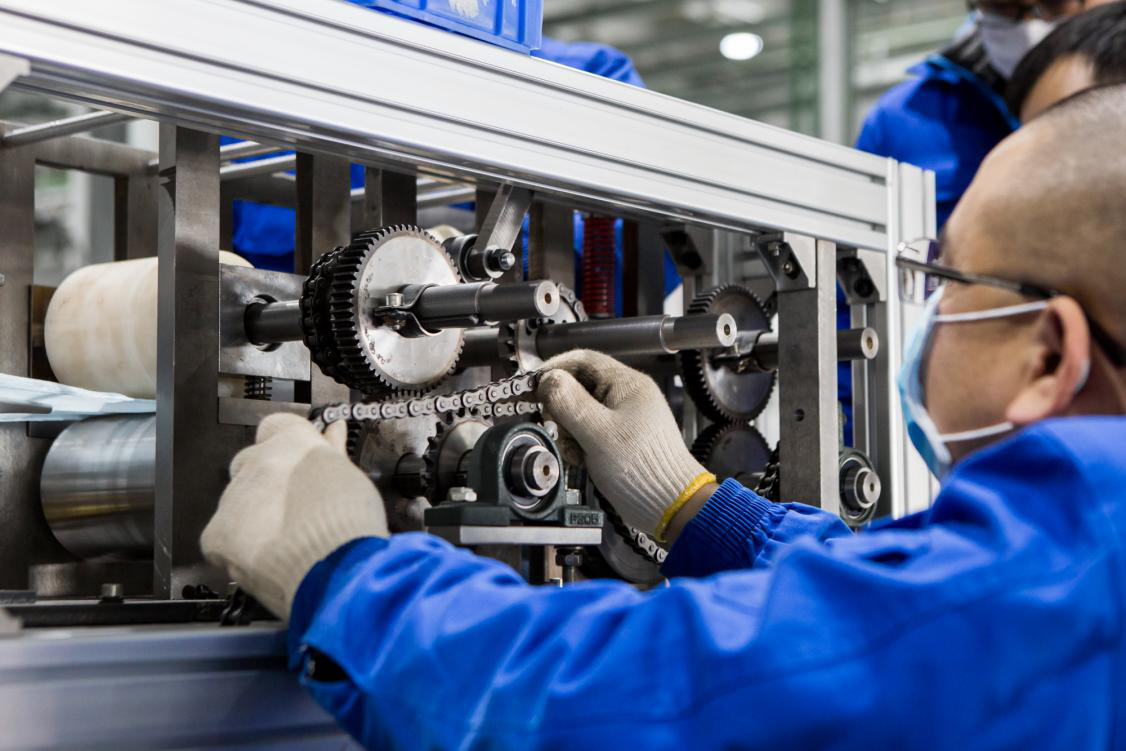

04. Preparation of spare parts for used pipe and pipe welding equipment

Spare parts for second-hand coiled pipe and welded pipe equipment will also become an important factor affecting the rapid commissioning of second-hand welded pipe equipment. Second-hand welded pipe equipment has many brands and various specifications. It is inevitable that parts will be damaged or need to be replaced during the installation and commissioning process, which can be quickly organized. , Deploying and repairing all kinds of accessories can fundamentally ensure that the second-hand coiled pipe welding equipment is put into production quickly, solve the customers’ concerns about buying second-hand pipe welded equipment, and make the second-hand pipe welded equipment more valuable.

05. Construction of production team for second-hand pipe coiling and welding equipment

With the equipment, site, installation and commissioning, and trial production, it is necessary to quickly set up an operation team so that the second-hand welded pipe equipment can be put into production quickly. Where can industry talents look for it? Different welded pipe types or different application fields of welded pipes have different requirements for talents. Only individuals and organizations who are familiar with product process requirements and have extensive industry contacts can quickly find suitable talents, build production teams, and put second-hand welded pipe equipment into production quickly .

Jinyujie Electromechanical Company, focusing on the welded pipe industry for 30 years, 20 years of welded pipe equipment manufacturing and service experience, serving customers more than 2000, has senior electrical, mechanical and welded pipe process engineers, to provide customers with cost-effective services; a large number of second-hand pipe welded pipe equipment resources , North and South 2 warehouses; close cooperation with many equipment manufacturers in the industry, can provide customers with a variety of spare parts, so that customers can buy second-hand welded pipe equipment without worries.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province