High frequency welded pipe equipment on the impact of welded tube blank defects on the quality of welded tube (8)

- Sort:Information

- Auth:

- Source:

- Release time:2022-10-07 11:30

- Pvs:

【概要描述】If the high frequency welded pipe equipment refers to the chemical composition and mechanical properties of welded tube blanks that require certain inspection methods to be known as invisible defects; then, those defects that can be seen only by vision are called tube blanks. Overt defect.

High frequency welded pipe equipment on the impact of welded tube blank defects on the quality of welded tube (8)

【概要描述】If the high frequency welded pipe equipment refers to the chemical composition and mechanical properties of welded tube blanks that require certain inspection methods to be known as invisible defects; then, those defects that can be seen only by vision are called tube blanks. Overt defect.

- Sort:Information

- Auth:

- Source:

- Release time:2022-10-07 11:30

- Pvs:

If the high frequency welded pipe equipment refers to the chemical composition and mechanical properties of welded tube blanks that require certain inspection methods to be known as invisible defects; then, those defects that can be seen only by vision are called tube blanks. Overt defect.

The dominant defects of the welded tube blank of the high frequency welded pipe equipment generally include cracked edges, broken edges, sawtooth, pitting, scratches, roll marks, dark spots, edge burrs, sickle bends, wrinkles, waves, edge warping, and points. Layers, warped skins, pinholes, sticky rolls, soft spots, rust, oxide layers, towers, loose rolls, etc. Let me introduce you to the causes of cracked edges and the impact of cracked edge billets on welded pipes.

Stratification

Layering refers to the phenomenon of two or more layers in the thickness direction of the tube blank. Stratification is divided into dominant and recessive. Dominant stratification can be judged by the naked eye without deformation. Invisible stratification can be seen only after deformation. Invisible stratification is more harmful than dominant.

Reasons for stratification:

(1) The oxide film on the surface of the molten steel is rolled into the inside of the steel ingot and is formed in the subsequent rolling.

(2) There is slag inclusion in the billet, which forms delamination after rolling.

(3) The necking and the parts below the necking during the solidification process of the molten steel are loose due to insufficient filling of the molten steel. The necking and looseness will form a layer or interlayer after rolling.

(4) Non-metallic inclusions. During casting, steel slag or refractory materials in the steel failed to float on the surface of the molten steel and were mixed in the steel ingot, and subsequent rolling formed delamination.

The effect of delamination on the quality of welded pipe:

(1) The tube blank is easy to deviate during the forming process, which leads to abnormal production. This is because when the layered tube is rolled by the upper and lower forming rolls of the open pass, the linear speeds of the upper and lower forming rolls are in fact not absolutely synchronized, so that the layered tube will slip irregularly.

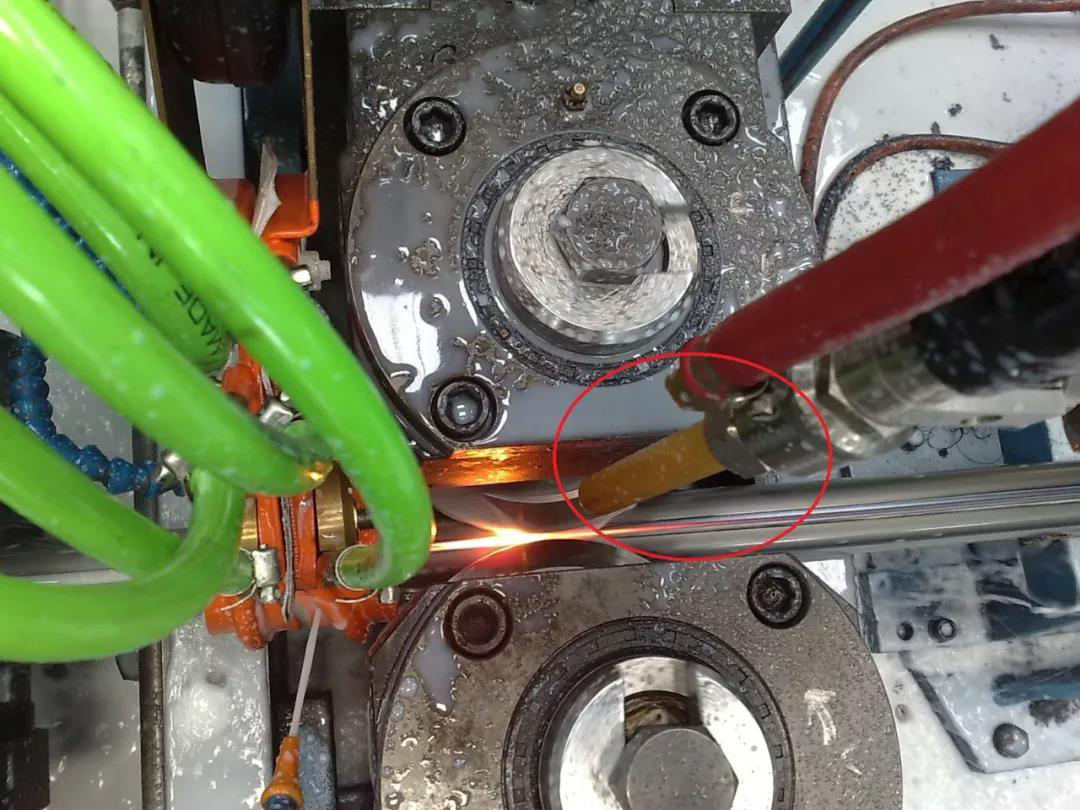

(2) Affect the quality of welds. If the edge of the tube is stratified, after being formed into an open tube to be welded, the inner layer of the tube should be compressed and the outer layer should be extended, causing the layered edge to be misaligned, resulting in a dislocation of the weld, and the outer burr is difficult to remove.

(3) Even if a tube is produced from the hidden layered tube blank, if it is not discovered in time during the production process, it will be more harmful, making it difficult for the welded tube to withstand the pressure of the normal wall thickness.

Regarding the defects of welded pipe blanks of high frequency welded pipe equipment (8), the causes of delamination and the effect of delamination on the quality of welded pipes, I hope it can help you.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province