Formation reasons for forming instability of thin-walled pipe in high frequency welded pipe production line

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-13 11:30

- Pvs:

【概要描述】The high frequency welded pipe production line of can be divided into thick-walled pipes and thin-walled pipes. The difficulty in forming thin-walled pipes and thick-walled pipes is clearly different. The difficulty in forming thin-walled pipes lies in the fact that the edges are generated during the forming process of the tube blank. Longitudinal extension is easy to produce bulge.

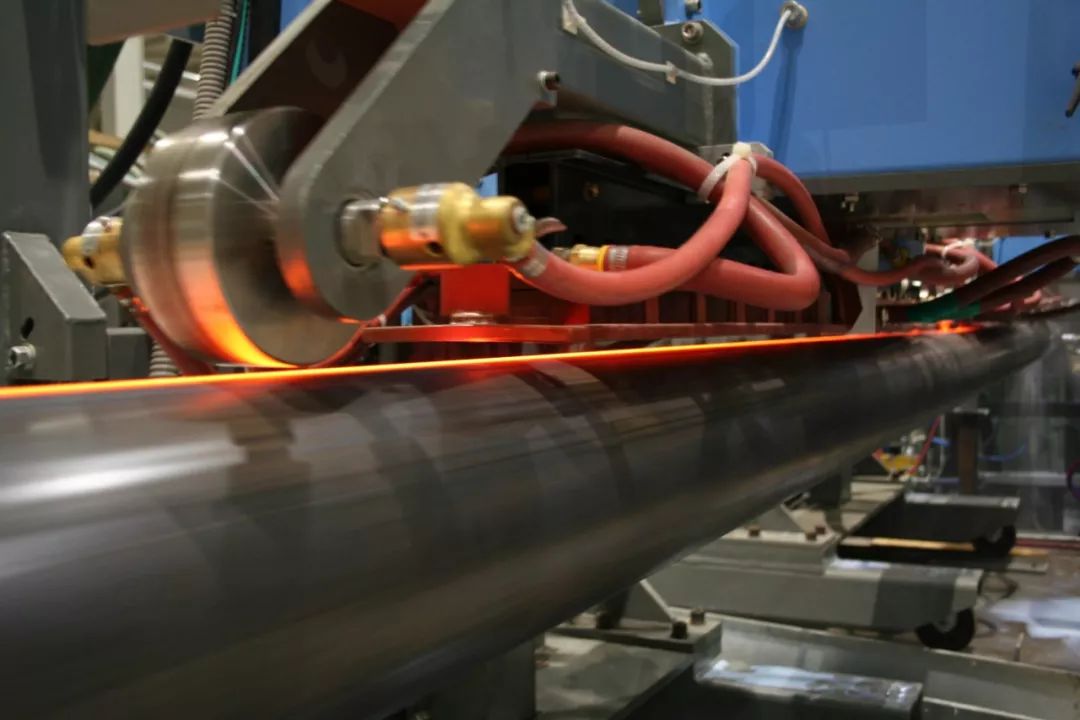

Formation reasons for forming instability of thin-walled pipe in high frequency welded pipe production line

【概要描述】The high frequency welded pipe production line of can be divided into thick-walled pipes and thin-walled pipes. The difficulty in forming thin-walled pipes and thick-walled pipes is clearly different. The difficulty in forming thin-walled pipes lies in the fact that the edges are generated during the forming process of the tube blank. Longitudinal extension is easy to produce bulge.

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-13 11:30

- Pvs:

The high frequency welded pipe production line of can be divided into thick-walled pipes and thin-walled pipes. The difficulty in forming thin-walled pipes and thick-walled pipes is clearly different. The difficulty in forming thin-walled pipes lies in the fact that the edges are generated during the forming process of the tube blank. Longitudinal extension is easy to produce bulge.

Thin-walled pipe, in theory, refers to a type of welded pipe with a wall-to-diameter ratio of less than 2%; in practice, welded pipes with a wall thickness of less than 0.6mm are also called absolute thin-walled pipes. The difficulty in forming thin-walled tubes is that the rigidity of the tube blank is low, and the edges are easy to lose stability, leading to forming failures.

The manifestation of forming instability

As mentioned earlier, there are two main manifestations of instability of thin-walled pipe forming in the high frequency welded pipe production line, one is wave and the other is bulge. In a sense, the process of forming thin-walled tubes is a process of restraining the formation of bulges.

However, under normal circumstances, even thin-walled tubes may not necessarily be bulging. Taking the adjustment operation as an example, the same thin-walled pipe, on the same pipe welding unit, uses the same set of forming rolls and the same tube blank raw material, and different operators sometimes have very different adjustment results. The formation of thin-walled tube forming instability in the high frequency welded pipe production line shows at least two points. ①The debugging operation of welded pipe has a brilliant effect in suppressing bulge and should be given great attention; ②There are many reasons for the bulge, but the formation mechanism is not complicated.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province