Explain the three welding states of high frequency welded pipe equipment

- Sort:Information

- Auth:

- Source:

- Release time:2022-05-02 11:30

- Pvs:

【概要描述】We judge whether the quality of the welded pipe meets the standard, generally through the welding process of the high frequency welded pipe equipment to deal with the welding seam. Well, we all know that there are three types of welding seams.

Explain the three welding states of high frequency welded pipe equipment

【概要描述】We judge whether the quality of the welded pipe meets the standard, generally through the welding process of the high frequency welded pipe equipment to deal with the welding seam. Well, we all know that there are three types of welding seams.

- Sort:Information

- Auth:

- Source:

- Release time:2022-05-02 11:30

- Pvs:

We judge whether the quality of the welded pipe meets the standard, generally through the welding process of the high frequency welded pipe equipment to deal with the welding seam. Well, we all know that there are three types of welding seams.

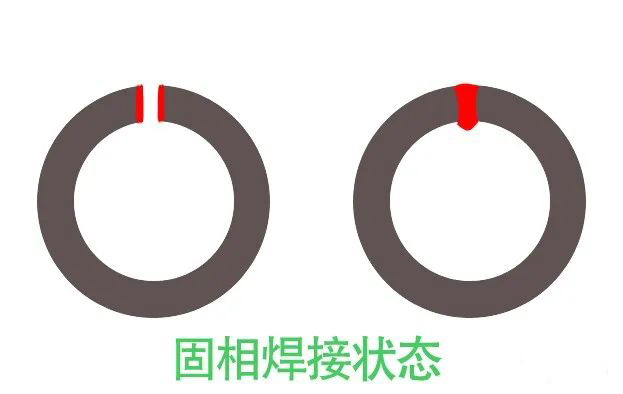

The welding form of high frequency welded pipe equipment: ① solid phase welding; ② solid fusion welding; ③ fusion welding.

Solid phase welding

It means that after the narrow area of the edge of the tube blank is heated to a high temperature of 1250~1300°C, the strong extrusion force conveyed by the extrusion roller squeezes the two edges of the tube blank together to form a common crystallization and realize welding. The feature of solid phase welding is that although the edge of the tube blank has reached the welding temperature, the heated area of the tube blank edge in the open corner area is narrow and still maintains the original shape, as shown in Figure 1. During the welding process, only a small amount of metal is extruded, forming extremely small internal and external burrs, the splashing sparks are small, and the burr height is generally not more than 30mm.

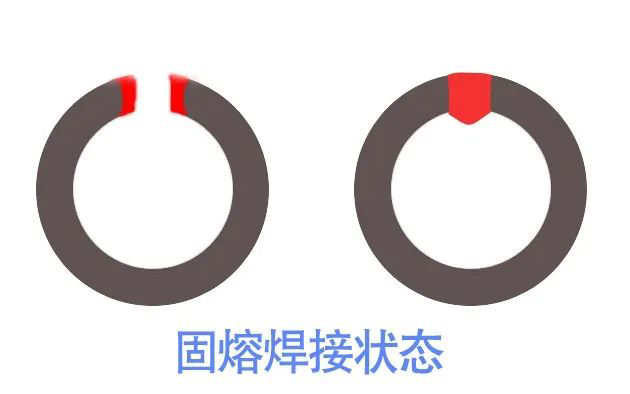

Solution welding

The performance reflected on the edge of the tube blank is that when the edge of the tube blank is heated to 1300~1400°C, the physical shape of the tube blank edge in the open corner area is no longer angular, especially near the apex of the corner, the contours of the two edges have been blurred, Even blending; at the same time, the heated area is much wider than that of the solid phase, see Figure 2, and the welding can be completed with only a large pressing force. During the welding process of the high frequency welded pipe equipment , part of the molten metal is extruded, forming large internal and external burrs, accompanied by more large sparks splashing around.

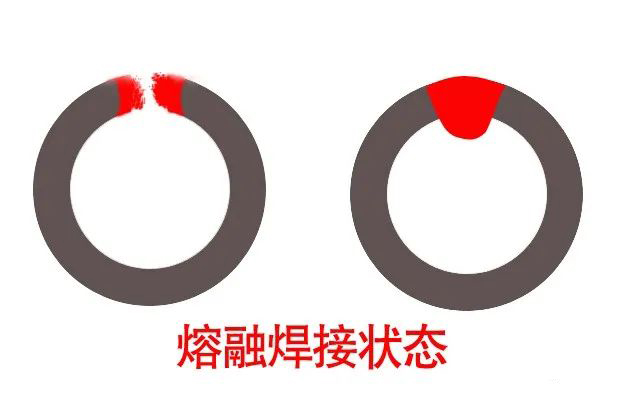

Fusion welding

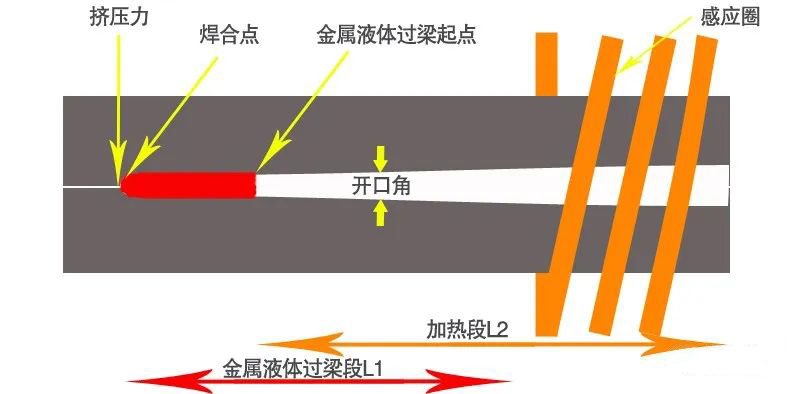

The edge of the tube blank is heated to above 1400 °C, the heating range of the edge is sharply widened, part of the metal is in a molten state, and the physical shape completely loses its regularity, as shown in Figures 3 and 4; the molten metal on both sides of the front end of the opening angle has "flowed "Together, a liquid lintel is formed, where the high-frequency current is highly concentrated, causing localized vaporization of the molten metal at the lintel. In this state, the two edges of the tube blank can be welded with only a small extrusion force; at the same time, a large amount of molten metal is easily extruded, and a large number of internal and external burrs are generated, accompanied by strong sparks.

In fact, the relationship between the three welding forms can be well explained by the length of the liquid lintel in Figure 4:

When the length of the liquid lintel is displayed as L, /2~L, /3, it is solid-fusion welding; when the length of the liquid lintel is reduced to L, ≈0, it is solid-phase welding.

In the actual production process of high frequency welded pipe equipment , the three welding forms are often intertwined, but the solid-fusion welding form is more favored by operators and is the most widely used. Both solid-phase welding and fusion welding have great application risks. Under the influence of many objective factors, the actual welding temperature is difficult to be strictly constant: in the solid-phase welding state, if the temperature is a little lower, the welding will not penetrate , to form cold welding; in the molten welding state, if the temperature is a little higher, it is bound to form over-burning defects; on the other hand, solid fusion welding, the welding temperature is a little higher or lower, the above problems will not occur, and it is easy to meet the process needs. In particular, if the customer requires a straight pipe with small internal burrs, solid-phase welding should be used; if a curved pipe with small internal burr is required, solid-fusion welding should be selected; of course, if welding high-strength thick-walled pipes, then, Fusion welding is the best choice.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province