Common faults of used welded pipe mills production line forming machines (1)

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-10 11:30

- Pvs:

【概要描述】Common faults of used welded pipe mills production line forming machines can be divided into ① deviation. ② scratches. ③ "indenter" phenomenon. ④ "drill belt" phenomenon. In order to let everyone understand the common faults of the molding machine in detail, we will introduce ① deviation.

Common faults of used welded pipe mills production line forming machines (1)

【概要描述】Common faults of used welded pipe mills production line forming machines can be divided into ① deviation. ② scratches. ③ "indenter" phenomenon. ④ "drill belt" phenomenon. In order to let everyone understand the common faults of the molding machine in detail, we will introduce ① deviation.

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-10 11:30

- Pvs:

Common faults of used welded pipe mills production line forming machines can be divided into ① deviation. ② scratches. ③ "indenter" phenomenon. ④ "drill belt" phenomenon. In order to let everyone understand the common faults of the molding machine in detail, we will introduce ① deviation.

The deviation is also called turning over the belt. Due to various reasons, the deviation will occur at any time between the rolls of the forming machine. The specific performance is that after the tube blank comes out of the flat roll or vertical roll, the heights of the two edges are different. In severe cases, the tube blank will turn over and cannot enter the next pass smoothly, so it is forced to stop processing, which directly affects the production. Increase in work rate. However, there are two reasons for the deviation of the forming machine of the used welded pipe mills production line, that is, the deviation of the flat roll and the deviation of the vertical roll. We will introduce them in detail according to these two reasons.

1.1 Analysis of the cause of the deviation of the flat roller

The deviation of the flat roll is mainly caused by the following reasons (excluding the defects such as the camber of the raw material).

(1) The center of the hole pattern is not correct.

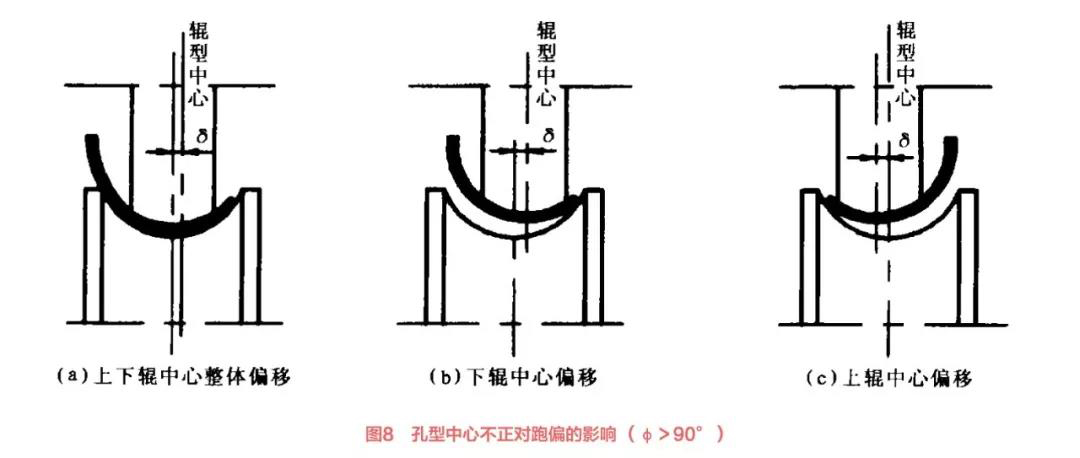

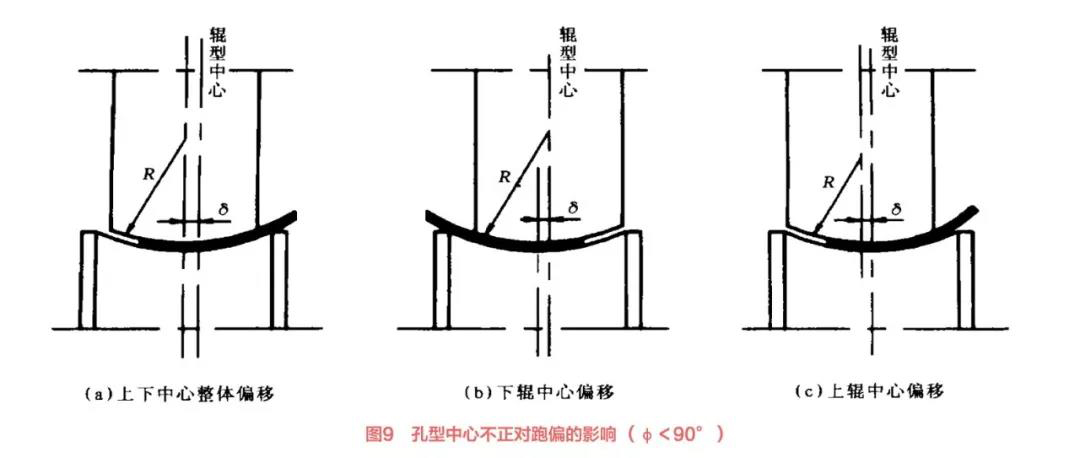

When the position of the center of the pass is not correct, the tube blank will deviate from the rolling center line during the rolling process and deviate. When the deformation angle of the pass is greater than 90°, and the center of the pass of the upper and lower rolls is not aligned, the tube blank will be turned up in the direction of the deviation of the center of the pass, as shown in Figure 8(a); when the center of the pass of the lower roll is not aligned, The tube blank will also be turned up in the direction of deviation from the center of the pass, as shown in Figure 8(b); when the center of the upper roll pass is not aligned, the tube blank will be turned up in the opposite direction, as shown in Figure 8(c). If the deformation angle of the tube blank is less than 90°, except when the upper and lower hole patterns are displaced as a whole, which is opposite to the deformation greater than 90° (as shown in Figure 9), the rest are in the same direction as the same type of offset. This is a specific manifestation of the deviation of the tube blank caused by the irregular center of the pass after several axial displacements of the roll. During the treatment, according to the assembly structure of the roll, check whether the positioning device and shaft of the roll have locking failure and looseness out of control, and adjust the tightening in time before production.

(2) Uneven pressure on the upper roller.

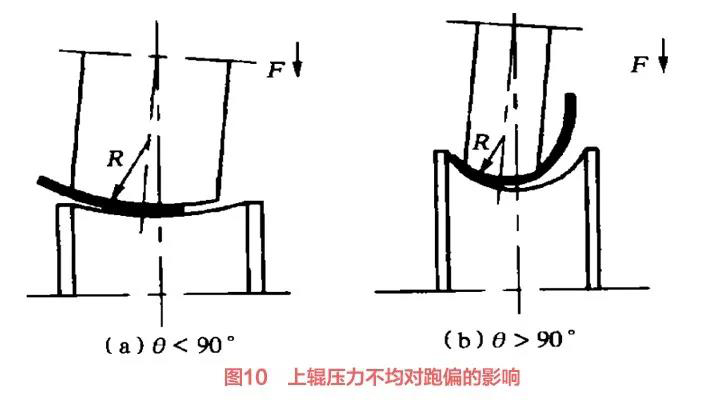

When the pressure of the upper roller is not uniform, it can cause the upper flat roller to be tilted and biased, so that the gaps on both sides of the upper and lower rollers are different.

That is, when the deformation angle is less than 90°, the tube blank will be turned up to the side with lower pressure, as shown in Figure 10(a); when the deformation angle is greater than 90°, the tube blank will be turned up to the side with higher pressure, as shown in Figure 10 ( b). The tube blank in the closed hole pattern will also rotate in the direction of less pressure to control the direction of the tube seam. In this case, adjust the pressing amount of the flat roll, keep the upper roll in a horizontal position, and make auxiliary direction adjustment with the help of the front vertical roll of the flat roll.

(3) Bearing damage.

Whether the bearing of the upper or lower roll is damaged, the reduction of the upper roll will change, resulting in the deviation of the tube blank. The deviation of the deviation is exactly the same as the deviation caused by the uneven pressure. In production, we need to detect the abnormal rotation sound of the bearing, or whether the touch part is hot, we can judge the damage degree of the bearing, and replace it in time without blind adjustment.

(4) Insufficient pressure.

What we mean by insufficient pressure means that after the upper roller is pressed, there is still a large gap between the tube blank and the pass, and the pass cannot completely or well control the tube blank and the deviation occurs. Its performance is that the tube blank floats during operation, and swings up and down from left to right. If it is in the lead, the head of the tube blank will be upturned, which can be solved as long as the reduction amount is appropriately increased.

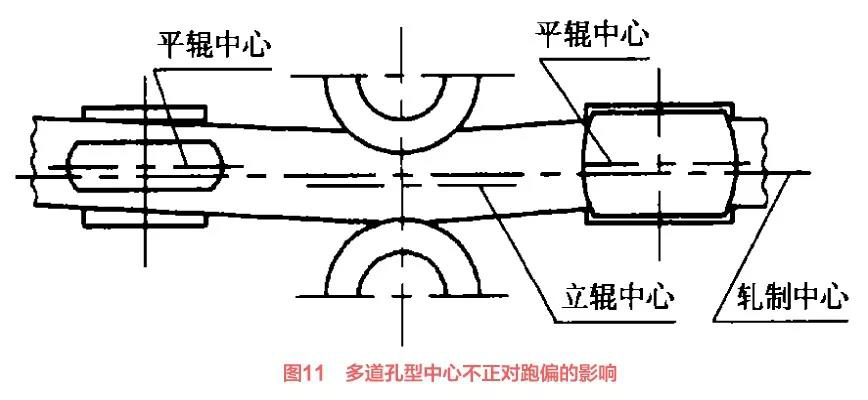

(5) Incorrect multi-pass hole type.

Incorrect multi-pass pass means that the center of two or more passes is not on the rolling line. When the tube blank deviates, a strange phenomenon often occurs during the adjustment. For example: When the tube blank is turned up to the outside, we will try to make it move inward according to the adjustment principle to overcome the problem of eversion. However, after the adjustment, the tube blank will suddenly turn inward when it continues to run, and sometimes the inward turning phenomenon will occur in the same direction at the back of the tube blank running. The conventional adjustment method cannot solve this problem. This is because the center of the multi-pass hole type is not correct. At this time, the tube blank is a twisting operation process in the forming machine (Fig. 11). For this deviation phenomenon, we should find the cause from the back of the tube blank, that is, find the problem from the first few passes of the forming machine, and make micro-adjustments and alignments one by one, so that the center of each pass is the same. When it can coincide with the rolling center, the deviation phenomenon can be fundamentally solved. This is the origin of the adjustment jargon that we often say is called "turning the back and adjusting the front".

(6) The center of the vertical roller is not correct.

The misalignment of the vertical roll center is also an important factor for the deviation of the tube blank after the flat roll comes out. The reason why this phenomenon is often overlooked is that the operation of the tube blank on the vertical roll is basically in a normal state, so in production, special attention should be paid to observe whether the tube blank is normal at the moment before it enters the flat roll after it comes out of the vertical roll. If the center of the vertical roller deviates, as long as we adjust the position of the vertical roller a little, we can control the best direction of the tube blank entering the flat roller, so that the deviation problem can be solved.

The reasons for the deviation of the common faults of the forming machine of the used welded pipe mills production line are mainly divided into the deviation of the flat roll and the deviation of the vertical roll. Today, we will introduce the analysis of the reasons for the deviation of the flat roll: ① The center of the hole is not correct.② The upper roll Uneven pressure.③Damage of pumping bearing ④Insufficient pressure.⑤Incorrect multi-pass hole type.⑥The center of the vertical roller is not correct.

More News

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province