Analysis of the structure of the induction coil of the used pipe welded machine

- Sort:Information

- Auth:

- Source:

- Release time:2023-03-23 11:30

- Pvs:

【概要描述】In the used pipe welded machine, the structure of the induction coil has three types: integral single-turn,integral multi-turn and split single-turn. The following is an overview of single-turn induction coils and multi-turn induction coils.

Analysis of the structure of the induction coil of the used pipe welded machine

【概要描述】In the used pipe welded machine, the structure of the induction coil has three types: integral single-turn,integral multi-turn and split single-turn. The following is an overview of single-turn induction coils and multi-turn induction coils.

- Sort:Information

- Auth:

- Source:

- Release time:2023-03-23 11:30

- Pvs:

In the used pipe welded machine, the structure of the induction coil has three types: integral single-turn,integral multi-turn and split single-turn. The following is an overview of single-turn induction coils and multi-turn induction coils.

The single-turn induction coil is mostly rolled with a single-layer copper plate with a thickness of 1.5~2mm, which is directly watered and cooled when used; it is also made of a double-layer copper plate with cooling water inside. Obviously, the cooling effect of the double layer is better than that of the single layer. It is better, but it is more troublesome to make. From the point of view of delivering welding energy, there is no difference between them. In practice, the double layer is used less.

The multi-turn induction coil is usually made of hollow round copper tube, which is connected with the cooling water of the unit to achieve simultaneous cooling inside and outside the induction coil. The main parameters of the induction coil include width, number of turns and inner diameter.

Generally, the adjustment of the induction coil of the used pipe welded machine is adjusted from the width of the induction coil, the number of turns of the induction coil, the inner diameter of the induction coil, and the protection of the induction coil.

Induction coil width

The width of the single-turn induction coil should be selected according to the pipe diameter, see Table 1. The overall single-turn induction coil is more suitable for small welded pipe units below 32; the split single-turn induction coil is more suitable for large and medium-sized welded pipe units. For example, if the induction coil is unfortunately damaged and needs to be replaced, the trouble and cost are not the induction coil itself, but the time cost of cutting off the tube and the resulting time cost; the split induction coil can be used without cutting the tube. Quick and cost-effective replacement.

The influence of the width of the induction coil on the output efficiency is as follows: if the induction coil is too wide, the voltage on the induction coil will drop due to the reduction in inductance, and then the actual power transmitted to the tube will drop; The resistance of the back of the tube is relatively small, and the active power loss is reduced, which is beneficial to improve the welding efficiency. Of course, for an induction coil that is too narrow, although the power transmitted to the tube increases, at the same time, the active power loss on the back of the tube also increases, which also reduces the actual welding power.

Induction coil turns

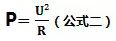

The increase in the number of turns means that the resistance increases. According to the relationship between the voltage U, the current I and the resistance R, U=IR (Formula 1), it can be known that when the number of turns (R) increases, the voltage U increases accordingly, indicating that the multi-turn induction The voltage across the coil is higher than that of a single-turn induction coil, which in turn transfers more power to the tube than a single-turn. Under the premise that there is still power remaining, the power is proportional to the square of the voltage on the induction coil, see the formula:

However, the above formula also reminds us that if the number of turns is increased too much, the current on the induction coil will be reduced, and the power transmitted to the tube will be reduced. It should be pointed out that there is a lot of talk here. In fact, it is generally 2-4 turns relative to 1. The pure copper tube with φ6-14mm (small welded tube unit below 114) is wound on the corresponding cylinder. completed, convenient and quick. As for whether it is better to use 2 turns or 3 turns or 4 turns, it cannot be generalized. The key depends on the matching, the equipment power, frequency, area and length of the impedance, the diameter and wall thickness of the copper pipe, the specification of the welded pipe, the inner diameter of the induction coil and the pipe to be welded. Factors such as the gap of the outer diameter of the billet, the gap between the turns of the induction coil and the cooling intensity, as long as any one of these factors changes, will affect the evaluation of the efficiency of a certain number of turns.

In addition, in addition to the influence of the number of turns on the welding efficiency, the width of the multi-turn induction coil is also an aspect. Experience has confirmed that when the total width of the multi-turn induction coil is about 10% narrower than that of a single turn, the effect is better.

Induction coil inner diameter

The essence of studying the inner diameter of the induction coil is to explore the gap between the outer diameter of the tube blank to be welded and the welding efficiency. The power transmitted by the induction coil to the tube blank to be welded is inversely proportional to the square of this gap (one side). ∆(increment)=2~4mm is suitable.

Induction coil protection

The focus of induction coil protection should be on anti-sparking and anti-collision

Anti-collision: When the apparent quality of the welded tube blank is poor and the joint is easy to break, it is recommended to take a larger value of ∆ (increment), and sometimes the induction coil can be preserved due to a small amount. Because the time cost, material cost, and labor cost of dealing with a broken belt and crashing the induction coil are often much larger than a little bit of efficiency gain, "don't be afraid of slowness, but be afraid of standing (stop)", this is the truth.

Anti-sparking: The induction coil for welded pipes transmits high-frequency current of 200-500kHz. Affected by the sharp angle effect of high-frequency current, the induction coil is most prone to tip discharge and ignition, similar to partial short circuit, which not only consumes part of the welding energy, shortens the induction In severe cases, it cannot be welded or even damage high-frequency equipment. Therefore, the outer surface of the induction coil should be covered with necessary protection treatment, and the induction coil should not be exposed as much as possible to eliminate sharp corners. The single-turn induction coil is usually dipped with a layer of high temperature resistant epoxy resin, and the multi-turn induction coil is recommended to be sheathed with a PTFE (F4) tube. The PTFE tube can be used for a long time at a high temperature of 260 ° C and still has good insulation performance, and the breakdown voltage is 25-40kV/mm. The relationship between the thickness of the F4 pipe wall and the anti-AC breakdown voltage is shown in Table 2

Adjust the induction coil of the used pipe welded machine according to the width of the induction coil, the number of turns of the induction coil, the inner diameter of the induction coil, and the protection of the induction coil, so as to effectively solve the problem of the welding seam of the welded pipe.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province