Adjust the basic work of forming in roll forming equipment

- Sort:Information

- Auth:

- Source:

- Release time:2022-05-15 11:30

- Pvs:

【概要描述】The basic forming adjustment in roll forming equipment includes four aspects: flat roll adjustment, vertical roll adjustment, roll change adjustment and forward-looking adjustment in the production process.

Adjust the basic work of forming in roll forming equipment

【概要描述】The basic forming adjustment in roll forming equipment includes four aspects: flat roll adjustment, vertical roll adjustment, roll change adjustment and forward-looking adjustment in the production process.

- Sort:Information

- Auth:

- Source:

- Release time:2022-05-15 11:30

- Pvs:

The basic forming adjustment in roll forming equipment includes four aspects: flat roll adjustment, vertical roll adjustment, roll change adjustment and forward-looking adjustment in the production process.

Forming flat roll adjustment

The adjustment of the flat roller can be summarized into three aspects: height adjustment, lifting and pressing, and moving left and right.

(1) Height adjustment: refers to the adjustment of the height of the lower flat roll according to the rolling bottom line. There are three control methods for the bottom line of the lower flat roll:

①Thread adjustment method. According to the worm gear and worm, the height of the lower roll is adjusted synchronously on both sides, so that the throat point of the hole shape of the lower roll is slowly approached to the preset rolling bottom line.

② pad method. Between the square slider and the arch bracket base, increase or decrease the corresponding thickness of the spacer, realize the adjustment of the height of the lower flat roller; its biggest advantage is stability, once it is adjusted, it will not change.

③ Flat roller bottom diameter method. The height of the lower shaft of some welded pipe units is not adjustable, and the measure to control the height of the rolling bottom line can only be based on the bottom diameter of the lower flat roll. For such roll forming equipment, the size of the bottom flat roll must be strictly controlled, especially when the lower flat roll is repaired. Attention should be paid to the control of the reduction of the bottom diameter.

(2) Lifting and pressing down: mainly adjust the upper flat roller.

① Indirect adjustment of worm gear. By turning the handwheel on the arch to drive the worm gear and the adjusting nut, the square slider, the upper shaft of the flat roller and the upper flat roller connected with the lifting screw can be adjusted for lifting. The advantage of this method is that the synchronous lifting performance is good and labor saving.

② The nut and screw are directly adjusted. Direct adjustment is performed by directly turning the adjusting nut-sleeve linkage lifting screw on the rack arch. The disadvantage is that it is easy to cause the two ends of the upper flat roller to rise and fall synchronously; the advantage is that the adjustment amount is more intuitive and easy to control.

③ Notes on the lifting and pressing of the upper roller. Attention must be paid to the invisible influence of the thread gap on the parallel rolling of the upper flat roll

(3)Move left and move right: Move the flat rollers on the flat roller shaft in the order of loosening first and then tightening by twisting the nuts on the flat roller shaft that constrain the movement of the flat roller at both ends.

The nut has three functions: ① to move the flat roll left and right to realize the symmetry of the flat roll about the rolling center line. ② to fasten the flat rolls to ensure that the flat rolls do not move about the rolling center line; at the same time, the fastening is of special significance for the "three-in-one" forming closed-pass upper roll. If the fastening is not tight, the "three-in-one" The pass will be opened by the forming tube blank, which will not only affect the forming quality, but also cause the roll pass to "drop meat" and be scrapped. ③ to measure the movement of the flat roller according to the pitch.

Forming vertical roller adjustment

Forming vertical roller adjustment includes height adjustment and lateral adjustment.

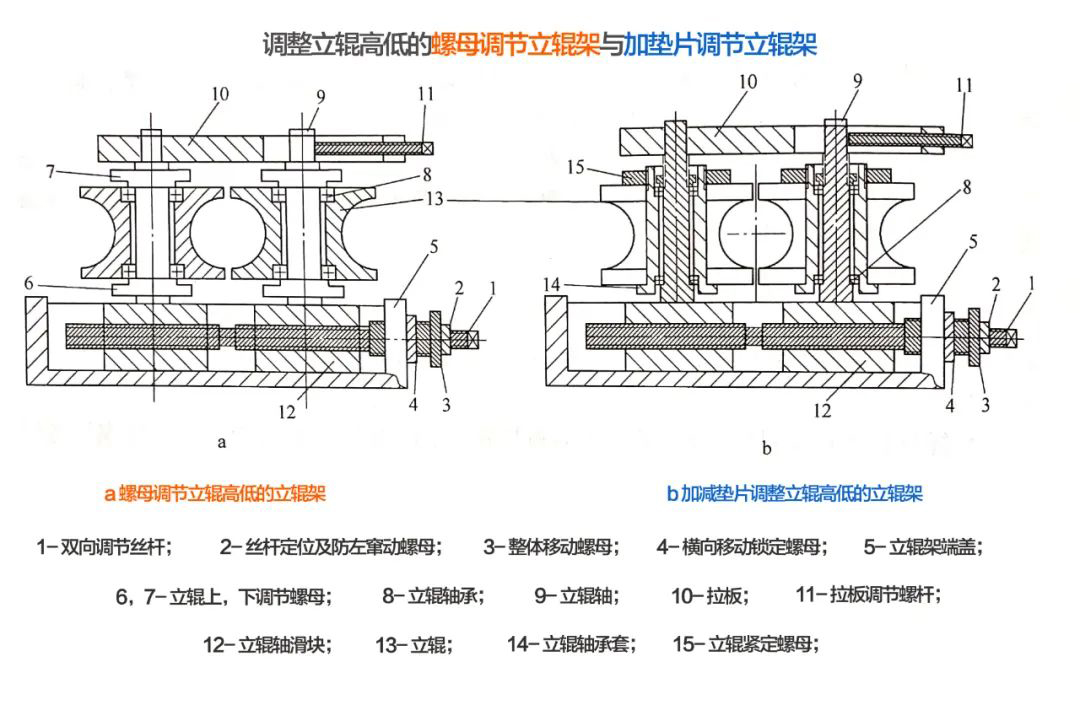

(1) The vertical roller height adjustment. According to the different structure of the vertical roller frame, there are two methods for adjusting the vertical roller lifting and lowering: the method of adding and subtracting shims and the method of nut adjustment.

① Nut adjustment method. The vertical roller is directly mounted on the vertical roller shaft by means of bearings, see the figure below. The height adjustment of the vertical roller depends on the upper and lower nuts on the vertical roller shaft. The advantage is that the height adjustment is more convenient, flexible and high precision; the disadvantage is the poor stability, especially when the bearing and the shaft are loosely fitted, the nut will rotate with the inner ring of the bearing, resulting in mold running and vertical roller shifting.

② Add and subtract shim method. The vertical roller is installed on a sleeve whose lower end is fixed and the upper end is locked by a nut, and the sleeve and the bearing are matched on the vertical roller shaft. When adjusting, first loosen the cap on the vertical roller sleeve, take out the vertical roller, and then add or subtract the corresponding gasket. The advantage of this method is that once it is set, it is relatively stable and not easy to change; the disadvantage is that it is inconvenient, especially for large and medium-sized pipes. If you want to adjust halfway, you need to disconnect the tube blank, which is more troublesome.

(2) Horizontal adjustment of vertical rollers. There are two types of vertical roller lateral adjustment: overall tightening and loosening, and overall left and right movement.

①The vertical rollers are collected and released together. Since the two-way adjusting screw 1 and the vertical axis slider 12 are matched with left- and right-handed threads, it is only necessary to turn the two-way adjusting screw 1 clockwise to reduce or increase the distance between the two sliders. , and the roll forming equipment drives the vertical roller to exert force on the tube blank through the vertical roller shaft, so as to achieve the effect of tightening or loosening the two vertical rollers at the same time; if the pulling plate adjusting screw 11 can be tightened or loosened at the same time, the effect will be better.

② The vertical roller moves in one direction as a whole. When moving the nut 3, its inner hole is slidingly matched with the two-way adjusting screw 1, and the outer thread is matched with the inner thread on the base end cover 5. When the whole moving nut 3 is rotated clockwise, the nut 3 moves to the left. At the same time, the left end of the nut 3 bears against the screw 1 and pushes the screw 1 to move to the left, thereby driving the slider, the vertical roller shaft and the two vertical rollers to move to the left at the same time; Only the vertical rollers move to the right at the same time.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province