What will affect the quality of welded pipes made by used welded pipe machines?

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-20 11:30

- Pvs:

【概要描述】How to make qualified welded pipes depends on the quality, and the quality of welded pipes depends on the production process of used welded pipe machines. So what problems sometimes occur in the production process of second-hand welded pipe equipment that affect the quality of welded pipes?

What will affect the quality of welded pipes made by used welded pipe machines?

【概要描述】How to make qualified welded pipes depends on the quality, and the quality of welded pipes depends on the production process of used welded pipe machines. So what problems sometimes occur in the production process of second-hand welded pipe equipment that affect the quality of welded pipes?

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-20 11:30

- Pvs:

How to make qualified welded pipes depends on the quality, and the quality of welded pipes depends on the production process of used welded pipe machines. So what problems sometimes occur in the production process of used welded pipe machines that affect the quality of welded pipes?

The main factors that affect the quality of welded pipe produced by used welded pipe machines are the influence of the edge condition of the strip on the quality of the welded pipe, the effect of the heating section on the quality of the thick-walled welded pipe, and the normalizing of the weld to improve the weld structure.

Influence of strip edge condition on welded pipe quality

In the trial production process, the welded pipe produced at the beginning was taken for flattening test. When the outer diameter of the steel pipe was reduced by less than 1/3, the weld cracked and the flaring test failed. After excluding the factors such as small extrusion force, insufficient strip width, and high temperature, it is found that when welding thick-walled pipes, the condition of the steel edge has a great influence on the welding quality.

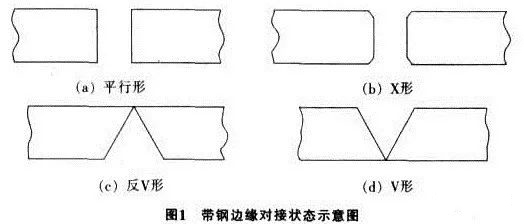

Ideally, the edge of the strip should be butt I or II, the butt III is slightly worse, and the butt IV is the least ideal. The butt state of the edge of the strip is shown in Figure 1 below.

When used welded pipe machines is welding steel pipes, the skin effect and proximity effect of high-frequency current make the current flow through the upper and lower surfaces of the steel pipe first, and the shortest loop of the V-shaped butt joint of the strip steel causes the heating rate of the lower half to be higher than that of the steel pipe. In the upper part, when the lower part is well welded, the upper part is insufficiently heated, and when the upper part reaches the normal welding temperature, the lower part is overheated. For the slitting steel strip used in production, due to the thickness of the slitting process, the upper half of the two sides of the same cutting edge are cut by rolling shears, and the lower half is the torn burr. Function, the burr part is 0.30~0.50 mm wider than the cut part. After rolling into a tube, the strip is V-shaped butt joint, and the welding is poor. In view of this situation, an edge planing device is added in the production, so that the edge of the strip can be butted in I-shaped or II-shaped, thus ensuring the welding quality.

Influence of heating section and burning section on the quality of thick-walled welded pipes

During the trial production, it was found that the low magnification metallographic structure of the welded pipe that did not pass the flattening and flaring test is: the double waist drum area is complete and clear, the middle waist reaches 1/3 of the wall thickness, and the rising angle of the metal streamline is about 50°. Standard. Observing the high magnification metallographic structure of the sample, the weld is relatively coarse Widmandarin structure + pearlite + ferrite on both sides of the inner and outer walls of the tube, and the structure in the middle part is coarse block, columnar ferrite + pearlite, this phenomenon It has not appeared in the welding of thin-walled pipes in the past.

The analysis shows that: when the edge of the tube blank is heated and welded, the temperature of the heating zone on the side of the tube blank is distributed in a gradient, and the temperature of the inner and outer surfaces of the tube blank is higher than that of the central part on the same section. During the welding process of the used welded pipe machines, when moving in the extrusion direction, the temperature of the central part is lower than the inner and outer surfaces of the tube blank. When the temperature reaches the welding temperature, the edge of the tube blank reaches a molten state, and the center and the edge melt unevenly. In this state The lower tube blank enters the extrusion section, which causes the coarse austenite grains to be distorted after being subjected to force, and is extruded and elongated under the action of external force. After cooling, they are fixed into directional columnar and strip-shaped crystals. It is manifested as coarse grains, small intergranular bonding force, and unqualified mechanical properties. This phenomenon is prominent when welding thick-walled tubes, but when welding thin-walled tubes, because the tube wall is thin, the temperature gradient of heating on the tube blank is not obvious. It reflects defects such as false welding and missing welding. Appropriately increase the distance between these two sections and reduce the high-frequency current, the problem will be solved.

Normalizing the weld to improve the weld structure

Since the welded steel pipe is manufactured after local heating, the welding area is affected by the comprehensive stress of heating, cooling, tissue stress, extrusion-compression-bending, etc. low, the mechanical properties are not uniform. The welding seam is normalized, the grain size of the welding area is refined to grade 7~8, the structure is improved, the welding area and the metal streamline formed after extrusion disappear, and the overall performance of the welded pipe is improved.

Our company has many brands and wide resources, there is always one suitable for you. You only need to tell us your pipe manufacturing needs, our company will provide you with used welded pipe machines that really suits your needs, welcome new and old customers to come to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province