Welding extrusion force of high frequency welded pipe machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-08 11:30

- Pvs:

【概要描述】To put it simply, the high frequency welded pipe machine usually uses the force of the squeeze roller to consist of two parts: one is the force required to squeeze the open tube to the contact between the two edges, and the other is the heat of the tube blank when the edge is welded. The force required to deform.

Welding extrusion force of high frequency welded pipe machine

【概要描述】To put it simply, the high frequency welded pipe machine usually uses the force of the squeeze roller to consist of two parts: one is the force required to squeeze the open tube to the contact between the two edges, and the other is the heat of the tube blank when the edge is welded. The force required to deform.

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-08 11:30

- Pvs:

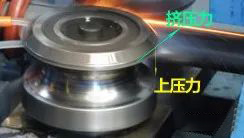

To put it simply, the high frequency welded pipe machine usually uses the force of the squeeze roller to consist of two parts: one is the force required to squeeze the open tube to the contact between the two edges, and the other is the heat of the tube blank when the edge is welded. The force required to deform.

The effect of squeezing force

The welding of high frequency welded pipe machine is a kind of pressure welding. After the two edges of the tube blank are heated to the welding temperature, the two edges need to be pressed together under a certain external force, and the oxides on the respective heating surfaces are extruded. Form common metal grains to achieve welding. The certain external force here is the extrusion force in the welded pipe production process, which is the most important process parameter in the welded pipe production process.

In essence, the extrusion force is not the bigger the better, and the proper extrusion force is the guarantee for obtaining high-quality welds.

When the extrusion force is insufficient, on the one hand, it is difficult for the oxides on the edge of the tube blank to be fully extruded, and non-metallic inclusions are formed in the weld seam, which destroys the continuity of the weld seam. During the flaring test, it will become the source of weld crack initiation. On the other hand, the small extrusion force makes the number of common crystals formed in the weld small, the structure is loose and not compact, and the weld is easy to crack after being stressed.

When the extrusion force of the high frequency welded pipe machine is too large, most of the high-temperature metal originally used for crystallization at the edge of the tube blank will be squeezed out of the weld, resulting in a small number of high-temperature metal crystals forming the weld. On the contrary, the metal that really forms the weld crystal is far from the edge of the tube blank and the temperature is not high, resulting in low welding strength.

Matching of extrusion force and welding form

It doesn't make sense to discuss the appropriateness of the squeeze force apart from the soldering temperature. The premise of whether the extrusion force is appropriate is whether the welding temperature is appropriate and kept constant. A larger extrusion force is more appropriate for solid-fusion welding, too large for fusion welding, and insufficient for solid-phase welding.

The method of judging the size of the squeezing force

(1) Average size method. It is to measure the horizontal "diameter" and vertical "diameter" of the tube blank entering and exiting the extrusion roller respectively, and then average them and compare them with the diameter of the extrusion roller hole. The former is slightly larger than the latter, which is regarded as the extrusion force. Normal; if the former is smaller than the latter, the corresponding force reduction adjustment is required.

(2) Reversing observation method. It is to reverse the tube from the extrusion roller to 50~80mm, and observe whether there are obvious "scratch marks" on the tube blank: if the "scratch marks" are obvious, it means that the extrusion force is too large; , it means that the extrusion force is more appropriate, if there is no "scratch mark", it means that the extrusion force is insufficient.

(3) Dynamometer. Usually only for reference.

(4) Destructive test. Through destructive tests such as bending, flaring, and flattening, the strength of the weld is checked to judge the extrusion force. The test method is the most reliable and convincing method among all the judgment methods, and it is also the most authoritative inspection method.

The above methods for judging the extrusion force in high frequency welded pipe machine have their own shortcomings and application limitations.

In addition: even if the extrusion force and welding temperature are just right within the specified range of the process, if the welding speed is not matched properly, high-quality welds will still not be obtained, which needs attention.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province