Weld quality failure caused by used welded pipe machines (9)

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-10 11:30

- Pvs:

【概要描述】When manufacturing welded pipes for used welded pipe machines, judging that the quality of the welded pipes meets the standard depends on the quality of the welds. Therefore, the quality of the weld is very important, so sometimes it is necessary to rule out the quality of the weld. We perform analyses to understand weld quality failures.

Weld quality failure caused by used welded pipe machines (9)

【概要描述】When manufacturing welded pipes for used welded pipe machines, judging that the quality of the welded pipes meets the standard depends on the quality of the welds. Therefore, the quality of the weld is very important, so sometimes it is necessary to rule out the quality of the weld. We perform analyses to understand weld quality failures.

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-10 11:30

- Pvs:

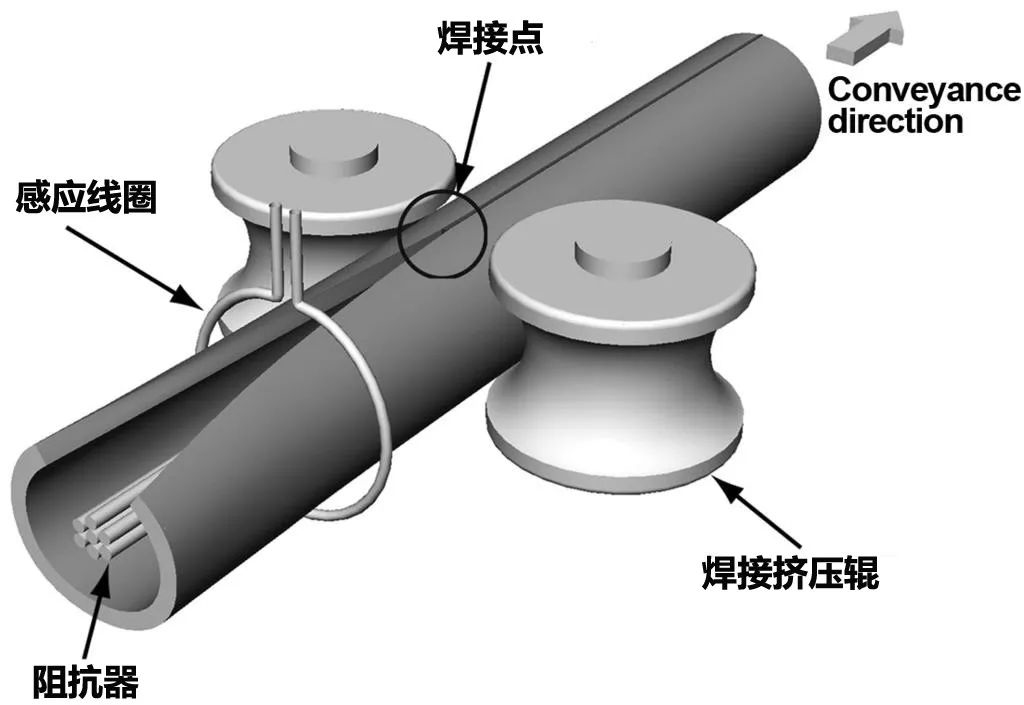

When manufacturing welded pipes for used welded pipe machines, judging that the quality of the welded pipes meets the standard depends on the quality of the welds. Therefore, the quality of the weld is very important, so sometimes it is necessary to rule out the quality of the weld. We perform analyses to understand weld quality failures.

These weld quality failures will occur when the used welded pipe machines is making pipes: ① through-length lap welding. ② Periodic lap welding. ③ Open the seam. ④ Trachoma. ⑤ Peach-shaped tube. ⑥ Weld seam gnawed. ⑦Outer burr planing. ⑧ Heating. ⑨ The current is small. ⑩ Melting of induction coils and electrodes. ⑪ Fire. ⑫ "No high pressure" phenomenon. We can summarize 12 causes of weld quality failures.

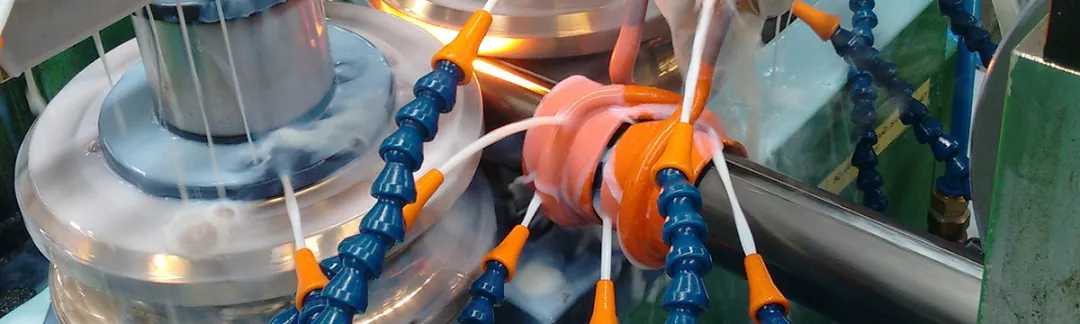

Fire

Ignition is actually a slight poor contact and short circuit performance. Generally, it will not cause any major accident, but only occasional open circuit and short circuit phenomenon. For example, if there is an iron layer at the contact part of the electrode contact with the tube blank, there will be sparks due to poor contact, and even the electrode will be heated and burned. When this happens, the electrode needs to be re-sharpened immediately. There is also a momentary contact between the induction coil and the pipe wall, which will also produce a spark phenomenon, which may sometimes burn through the induction coil. In addition, there are some metal objects that overlap the electrodes and the induction coil to cause ignition. This ignition is a slight short-circuit phenomenon. Generally, such metal objects will be instantly melted by the current. However, sometimes Various scars will be left on the tube wall.

No high pressure phenomenon

In production, sometimes there is a sudden loss of output current during welding, which makes production unable to continue. We commonly call this phenomenon "no heating" or "no high voltage". There are two main reasons for "no high voltage",(1) the internal electrical problem of the high-frequency equipments.(2) the problem of the external power transmission equipments. Below we only describe some common problems below the secondary coil of the output transformer, because this part should belong to the scope of production process adjustment.

The reason for "no high voltage" caused by external equipment is mainly caused by the discharge phenomenon. The discharge occurs mostly between the primary coil and the secondary coil of the output transformer, between the primary coil itself and the insulation parts below the secondary coil. Sometimes the discharge phenomenon has obvious manifestations, such as arc light and open flame generated at the discharge place. Sometimes there is no performance, such as carbonization of the insulator, instantaneous poor contact and short circuit, etc., which requires us to check each contact part and insulation part one by one. Failures generally occur at these links.

The above is one of the reasons for the quality failure of the welding seam when the used welded pipe machines is making pipes, sparking and "no high pressure" phenomenon. The main reasons for the phenomenon of "no high voltage" are (1) the internal electrical problems of high-frequency equipment. (2) Problems with external power transmission equipment. The reason for the formation of sparks is mainly a slight poor contact and short circuit performance.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province