Weld quality failure caused by used welded pipe machines (8)

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-07 11:30

- Pvs:

【概要描述】When manufacturing welded pipes for used welded pipe machines, judging that the quality of the welded pipes meets the standard depends on the quality of the welds. Therefore, the quality of the weld is very important, so sometimes it is necessary to rule out the quality of the weld. We perform analyses to understand weld quality failures.

Weld quality failure caused by used welded pipe machines (8)

【概要描述】When manufacturing welded pipes for used welded pipe machines, judging that the quality of the welded pipes meets the standard depends on the quality of the welds. Therefore, the quality of the weld is very important, so sometimes it is necessary to rule out the quality of the weld. We perform analyses to understand weld quality failures.

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-07 11:30

- Pvs:

When manufacturing welded pipes for used welded pipe machines, judging that the quality of the welded pipes meets the standard depends on the quality of the welds. Therefore, the quality of the weld is very important, so sometimes it is necessary to rule out the quality of the weld. We perform analyses to understand weld quality failures.

These weld quality failures will occur when the used welded pipe machines is making pipes: ① through-length lap welding. ② Periodic lap welding. ③ Open the seam. ④ Trachoma. ⑤ Peach-shaped tube. ⑥ Weld seam gnawed. ⑦Outer burr planing. ⑧ Heating. ⑨ The current is small. ⑩ Melting of induction coils and electrodes. ⑪ Fire. ⑫ "No high pressure" phenomenon. We can summarize 12 causes of weld quality failures.

Melting of induction coils and electrodes

Whether it is the induction coil or the electrode, sometimes it will be burned red by a strong current in an instant. If the high-frequency current output is not turned off in time, it will be melted and an open circuit will occur, causing other electrical accidents. The main reasons for this accident are as follows:

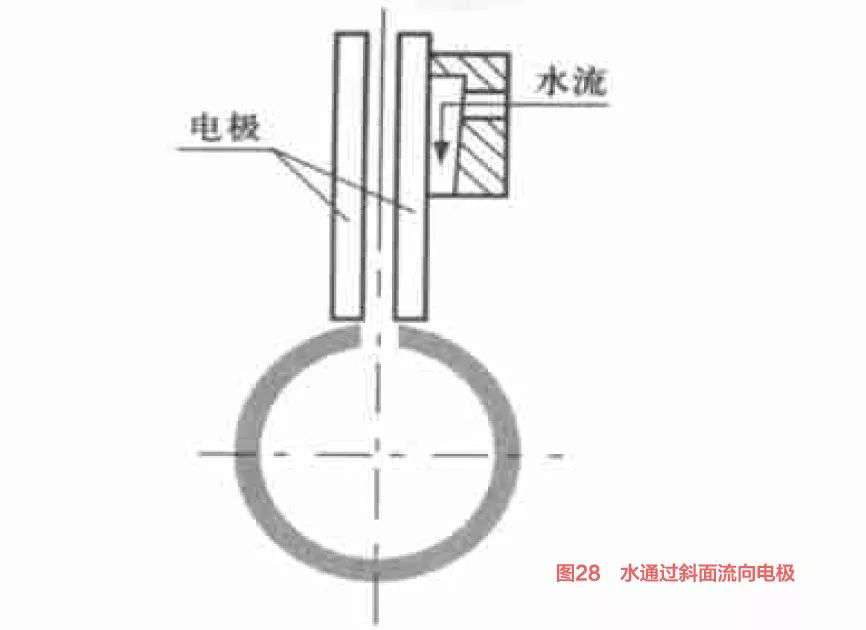

(1) Water cooling. The red-burning and melting phenomenon of the induction coil and the electrode has a great relationship with the cooling effect of water. When there is a dew hole in a certain part of the induction coil, the cooling water will be shunted, so that the induction coil cannot be cooled in time and effectively during work, and it will be burnt and melted. Especially for electrodes used in contact welding, water cooling requires not only a flow rate and flow, but also the water flow to slide down against the outer surface of the electrode without forming a space in the middle (Figure 28).

In production, we sometimes feel that the amount of water is very large, but the phenomenon that the electrode still burns red is the reason. At the same time, we can use our fingers to feel the impact strength of the water. When we feel that the fingers are obviously impacted, it means that the flow rate of the water is relatively satisfactory.

(2) Poor contact. Poor contact will lead to poor conduction of the circuit, and after being locally impacted by a large current, the conductor will quickly start to arc and heat up and burn. For example, when the screw parts that clamp and fix the induction coil and the pressing plate of the electrode contact are loosened, it will cause the ignition and heat damage of the local parts.

The above is one of the reasons for the quality failure of the welding seam when the used welded pipe machines is making pipes, the melting and pouring of the induction coil and the motor. The main reasons for the formation of the induction coil and the melting of the motor are (1) water cooling (2) poor contact.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province