Used welded pipe machine welded pipe production process specification—slitting process

- Sort:Information

- Auth:

- Source:

- Release time:2022-10-03 11:30

- Pvs:

【概要描述】In the production of used welded pipe machine , it is necessary to know the production process regulations of each equipment in order to operate the Chinese used welded pipe mills according to the production process regulations.

Used welded pipe machine welded pipe production process specification—slitting process

【概要描述】In the production of used welded pipe machine , it is necessary to know the production process regulations of each equipment in order to operate the Chinese used welded pipe mills according to the production process regulations.

- Sort:Information

- Auth:

- Source:

- Release time:2022-10-03 11:30

- Pvs:

In the production of used welded pipe machine , it is necessary to know the production process regulations of each equipment in order to operate the Chinese used welded pipe mills according to the production process regulations.

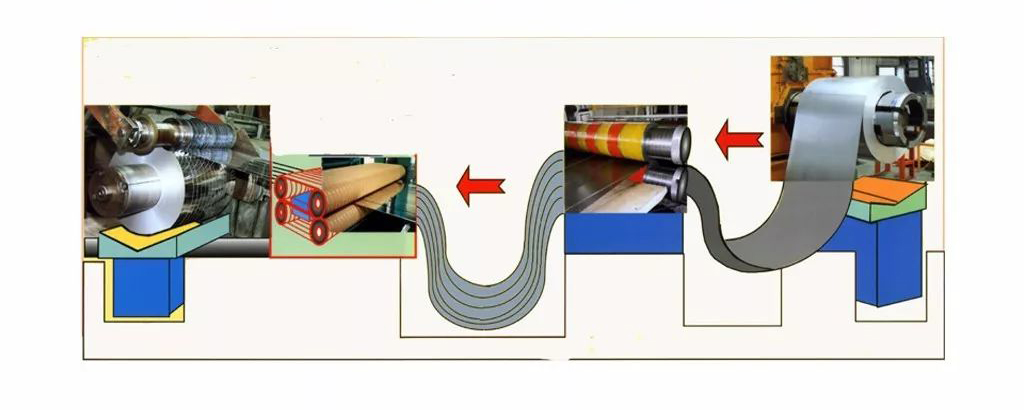

In the first step, we first understand the slitting process of used welded pipe machine

1. Check whether the external dimensions of the strip coils of the used welded pipe machine are the strip steel required for production, and secondly, whether the strip steel is defective, and report any problems to the leader of the class in time.

2. After the feeder chooses the strip steel to check the safety of the spreader, he lifts the strip steel onto the loading trolley, leaving a certain size between the two cones for loading.

3. Drop the sling steel vertically so that its center and the center of the cone are approximately on the same horizontal line and between the two cones.

4. Open the shovel head of the straight-end machine while lowering the pressure roller, and then start the motor of the uncoiler to make the head turn on the plane of the shovel head.

5. Turn off the decoiler motor, turn on the straightening machine motor to drive the strip to move forward until the hydraulic shear.

6. Turn on the hydraulic shears, turn on the hydraulic shears to take the lead under the principle of no lack of ruler and no waste, to prevent the waste from splashing, and then lift the hydraulic shears.

7. Restart the leveler motor to feed the strip into the cutting blade.

8. Turn on the cutting blade motor to drive the strip into the slitting blade. After measuring the size, turn on the cutting blade motor to send the strip to the coiler section.

9. After the strip is cut, the blanker immediately attaches the newly cut waste wire head to the scrap edge coiler, and at the same time inspects whether the quality of the cut strip meets the requirements of the slitting process card;

10. When the cut strip reaches the reeling shaft, the blanker inserts the strip head into the coiling seam of the coiler;

11. Start the coiling motor until the whole strip is cut.

12. When the tail of each coil is on the reeling shaft, the blanking worker must tie it with the refined strip with iron wire or waste wire to prevent loose coils;

13. Open the hydraulic device to exit the steel coil and put it on the unloading trolley;

14. Put the cut steel coil neatly into the designated position.

After learning the slitting process, the actual operation principle of strip steel of used welded pipe machine can be carried out according to the slitting process.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province