Used steel pipe rolling mills ,Types of external burrs appearing in

- Sort:Information

- Auth:

- Source:

- Release time:2021-11-13 11:30

- Pvs:

【概要描述】The external burr shape appears when the used steel pipe rolling mills. The shape of the burr inside the welded pipe has a certain logical relationship with the welding temperature, extrusion force and welding speed.

Used steel pipe rolling mills ,Types of external burrs appearing in

【概要描述】The external burr shape appears when the used steel pipe rolling mills. The shape of the burr inside the welded pipe has a certain logical relationship with the welding temperature, extrusion force and welding speed.

- Sort:Information

- Auth:

- Source:

- Release time:2021-11-13 11:30

- Pvs:

The external burr shape appears when the used steel pipe rolling mills. The shape of the burr inside the welded pipe has a certain logical relationship with the welding temperature, extrusion force and welding speed.

The operator can see the essence of the operating state of the used steel pipe rolling mills through the phenomenon of the shape of the external burr.

Correlation between matching state of speed, temperature, extrusion force and external burr shape

External burr shape: bifurcated

Speed and temperature extrusion force matching status: welding heat is too low, welding speed is too fast, and extrusion force is too small.

Adjustment measures: immediately reduce the speed or increase the welding heat or increase the extrusion force.

External burr shape: linear

Speed and temperature extrusion force matching status: welding heat is low, welding speed is high, and extrusion force is low.

Adjustment measures: increase the welding heat or reduce the speed or increase the squeezing force appropriately.

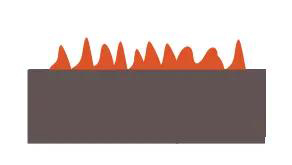

External burr shape: small hilly shape

Speed and temperature extrusion force matching state: maintain current operation.

Adjustment measures: normal production + pay attention to observation

External burr shape: large hilly shape

Speed and temperature extrusion force matching status: welding heat is too high, welding speed is too low, and the extrusion force is too large.

Adjustment measures: Immediately reduce the welding heat or accelerate, or appropriately reduce the squeezing force.

The above are the types of external burrs that appear when the used steel pipe is rolled by machine-made pipes. The essence of the running state of the used steel pipe rolling mills can be analyzed through the shape of the external burr.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province