Used round tube forming machines induction heating welding seam heat treatment method

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-08 11:30

- Pvs:

【概要描述】According to the steel types and mechanical properties listed in Table 2, the main heat treatment methods to improve the comprehensive performance of welds include normalizing treatment, normalizing + tempering treatment, quenching + tempering treatment and other methods. At present, domestic used round tube forming machines mostly use weld normalizing treatment in the production of welded pipes, and other heat treatment methods have not yet been used. The most advanced heat treatment of welded pipes is quenching and tempering. In foreign large-scale welded pipe production lines, normalizing treatment is often used, and quenching and tempering treatment is only used by individual companies in Japan, the United States and the European Union. Induction heating and tempering treatment of welds is the future direction of development.

Used round tube forming machines induction heating welding seam heat treatment method

【概要描述】According to the steel types and mechanical properties listed in Table 2, the main heat treatment methods to improve the comprehensive performance of welds include normalizing treatment, normalizing + tempering treatment, quenching + tempering treatment and other methods. At present, domestic used round tube forming machines mostly use weld normalizing treatment in the production of welded pipes, and other heat treatment methods have not yet been used. The most advanced heat treatment of welded pipes is quenching and tempering. In foreign large-scale welded pipe production lines, normalizing treatment is often used, and quenching and tempering treatment is only used by individual companies in Japan, the United States and the European Union. Induction heating and tempering treatment of welds is the future direction of development.

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-08 11:30

- Pvs:

Pipeline steels are mainly among the steels whose welds require heat treatment to improve their mechanical properties. Steels used for different strength grades and their room temperature requirements are listed in Table 2.

According to the steel types and mechanical properties listed in Table 2, the main heat treatment methods to improve the comprehensive performance of welds include normalizing treatment, normalizing + tempering treatment, quenching + tempering treatment and other methods. At present, domestic used round tube forming machines mostly use weld normalizing treatment in the production of welded pipes, and other heat treatment methods have not yet been used. The most advanced heat treatment of welded pipes is quenching and tempering. In foreign large-scale welded pipe production lines, normalizing treatment is often used, and quenching and tempering treatment is only used by individual companies in Japan, the United States and the European Union. Induction heating and tempering treatment of welds is the future direction of development.

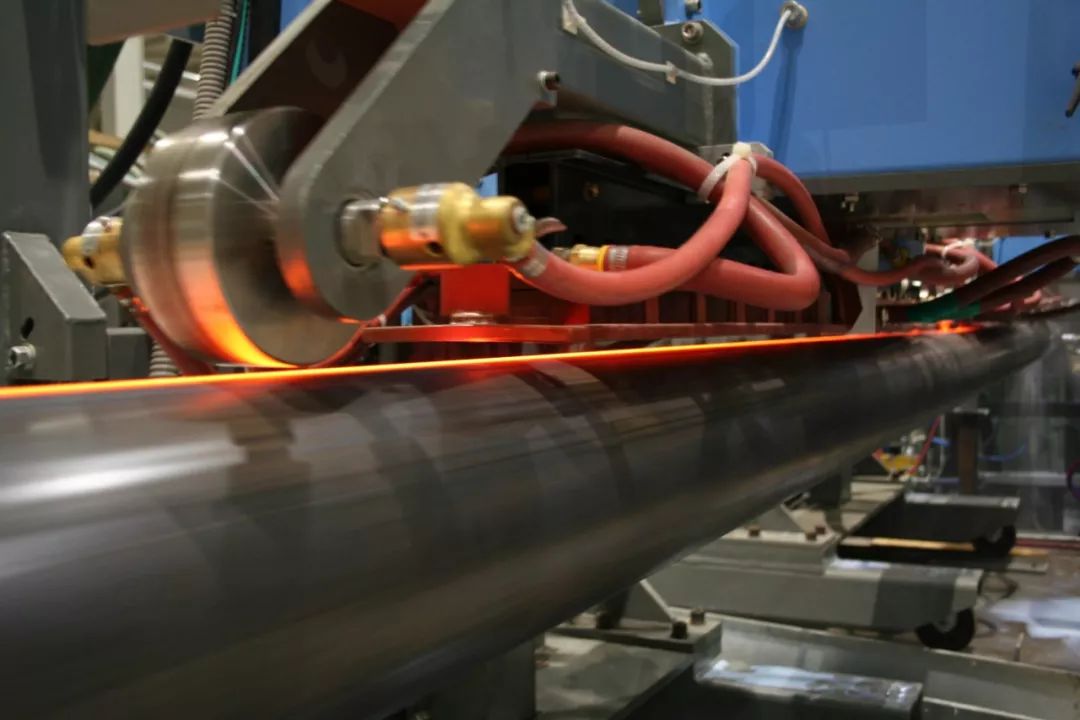

(1) Induction heating and normalizing of welds. The normalizing of welds includes annealing, which is sometimes called stress relief annealing. The welding seam induction heating and normalizing treatment is to heat the weld seam to a temperature above Ac3, and then air-cool it to below 400 ℃ and water-cool it to room temperature after 900-950 ℃. The used round tube forming machines can eliminate the internal stress of welding, refine the grains of the weld, improve the microstructure, and improve the plasticity and impact toughness of the weld. Induction heating and normalizing treatment of welds is suitable for ordinary low-alloy steel and some low-alloy high-strength steels, equivalent to welded pipes below X60 steel grade. The induction heating annealing treatment of the weld is to heat the weld to 700-750 ℃ dual-phase region, and then air-cool to normal temperature, in order to eliminate the internal stress of the welding and improve the plasticity. Annealing treatment is mainly used for carbon steel and some ordinary low alloy steel welded pipes.

(2) Induction heating normalizing + tempering treatment of the weld seam. When the hardness of the weld seam is still high and the plasticity is still low after normalizing treatment, high temperature tempering treatment can be used to remedy. Induction heating and tempering treatment is to heat the weld to a temperature below Ac1, usually air-cooled at about 650°C. After high temperature tempering treatment, the martensite structure in the original steel is transformed into tempered sorbite and ferrite, the plasticity of the weld increases, and the hardness decreases and the strength changes little.

(3) Weld induction heating quenching + tempering treatment, this heat treatment method is also called quenching and tempering treatment. The online welding seam induction heating quenching and tempering treatment of used round tube forming machines is the most advanced heat treatment technology. After the quenching and tempering treatment, the comprehensive mechanical properties of the welded seam completely reach the level of the pipe body, and the performance of the welded seam and the pipe body is uniform. The core of realizing this heat treatment technology is to master the transverse magnetic field heating technology to ensure the uniform and accurate heating temperature. For low-alloy high-strength steel and micro-alloyed high-strength steel welds, the quenching heating temperature is 900-950 ℃, and the tempering heating temperature is 600-650 ℃. The quenching adopts spray cooling, and the tempering adopts air cooling and water cooling combined cooling. . When the quenching and tempering temperature is heated by longitudinal magnetic field, the accuracy of temperature control can reach ±10℃, which is the necessary temperature control level for high-strength welded pipes to maintain stable performance. The use of transverse magnetic fields to heat welds also requires high temperature control accuracy.

Our company has many brands and wide resources, there is always one suitable for you. You only need to tell us your pipe manufacturing needs, our company will provide you with used welded pipe equipment that really suits your needs, welcome new and old customers to come to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province