Used round tube forming machines induction heating weld normalizing treatment

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-11 11:30

- Pvs:

【概要描述】Normalizing treatment is currently the most widely used heat treatment method for welded pipe welds in domestic used round tube forming machines, and is sometimes called weld annealing treatment. The difference between the two is that the heating temperature of normalizing treatment is above Ac3, and the heating temperature of annealing treatment is lower, near A c1. For pipeline steel welded pipes, weld normalizing treatment is one of the heat treatment methods in the API standard.

Used round tube forming machines induction heating weld normalizing treatment

【概要描述】Normalizing treatment is currently the most widely used heat treatment method for welded pipe welds in domestic used round tube forming machines, and is sometimes called weld annealing treatment. The difference between the two is that the heating temperature of normalizing treatment is above Ac3, and the heating temperature of annealing treatment is lower, near A c1. For pipeline steel welded pipes, weld normalizing treatment is one of the heat treatment methods in the API standard.

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-11 11:30

- Pvs:

Normalizing treatment is currently the most widely used heat treatment method for welded pipe welds in domestic used round tube forming machines, and is sometimes called weld annealing treatment. The difference between the two is that the heating temperature of normalizing treatment is above Ac3, and the heating temperature of annealing treatment is lower, near A c1. For pipeline steel welded pipes, weld normalizing treatment is one of the heat treatment methods in the API standard.

Weld induction heating normalizing treatment can be divided into online normalizing treatment and offline normalizing treatment according to its production configuration. Offline normalizing can be used for products with many specifications and small batches. Online normalizing should be used when product specifications are small and large batches.

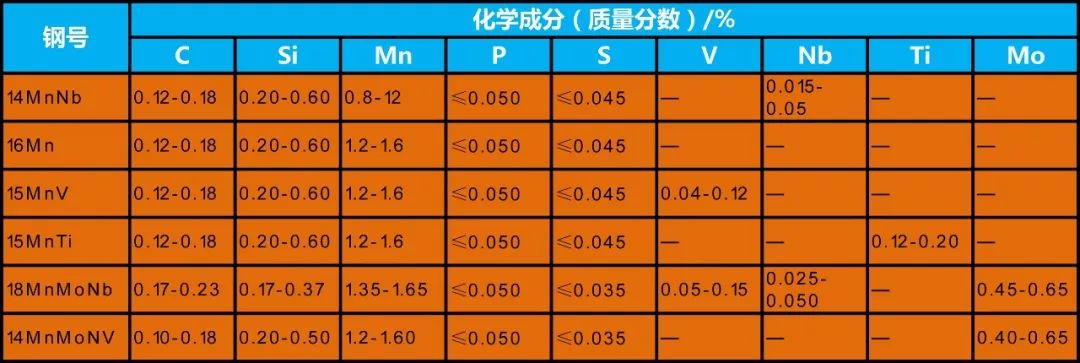

Induction heating and normalizing treatment of welds is mainly used for low carbon and low alloy steel welded pipes strengthened with vanadium, niobium and titanium elements. The chemical composition of this type of steel is listed in Table 3. The purpose of normalizing the weld is to eliminate the internal stress generated by welding, refine the grain of the weld metal, improve the plasticity and toughness of the metal, and reduce the performance difference between the weld and the pipe body.

Selection of Induction Heating Normalizing Temperature for Weld Seam

The normalizing temperature of the used round tube forming machines in the traditional low alloy steel is 30-50 ℃ above Ac3. However, when the heating rate of induction heating is 20-50℃.s-1, Ac3 will move up with the increase of heating rate. According to the experience of induction heating quenching temperature, Ac3 will increase by 20-50℃, therefore, the normalizing temperature of induction heating low alloy steel weld should be selected at 50-100℃ above Ac3. The upper limit is taken when the steel contains Cr, V, and Ti alloying elements, and the lower limit is taken when these alloying elements are not contained. The Ac3 of the normalized steel listed in Table 3 below is 860-880℃, and the normalizing temperature for induction heating can be selected at 910-980℃.

The normalizing heating temperature should not be too high. Under normal heating conditions, the initial austenite grains of low-alloy hypoeutectoid steel begin to grow from 900 ℃, and grow rapidly above 950 ℃. Therefore, too high normalizing temperature is not conducive to refining the grain structure of the weld and reducing the effect of normalizing treatment. In addition, too high normalizing temperature will also aggravate metal oxidation in the weld zone, affect the surface quality of the welded pipe and reduce the yield of steel. Similarly, if the normalizing temperature is too low, the plasticity and toughness of the weld metal cannot be improved, and the purpose of normalizing treatment cannot be achieved.

Weld seam induction heating normalizing holding time and cooling method

The selection of welding seam induction heating and normalizing holding time, quenching, solid solution and normalizing treatment are all heat treatment methods for heating the steel to austenitizing temperature and cooling it at different cooling rates. The three treatments are the same for the purpose of austenitizing. Induction heating low alloy steel quenching treatment and austenitic hot-strength steel solution treatment, the test of canceling the austenitizing holding time, the results show that as long as the induction heating quenching and solution temperature is 50- After 100 ℃, the same heat treatment effect can be achieved without holding time, the solid solution amount of the strengthening elements is consistent, and the room temperature and high temperature mechanical properties after tempering and aging treatment are higher than those of the traditional treatment process. It can be seen that the cancellation of the holding time during the induction heating and normalizing process of the used round tube forming machines will not affect the effect of the later heat treatment. Table 4 shows that the mechanical properties of 10 steel welded pipes after induction heating without holding time annealing have achieved good results.

To sum up, for low-alloy hypoeutectoid steel, as long as the normalizing temperature of induction heating is properly selected and the welding seam heating temperature is uniform, the normalizing holding time can be completely cancelled without affecting the heat treatment effect. Because, considering the phase transformation rate of metal structure, temperature plays a decisive role, and the effect of temperature is much greater than the time factor, and changing time with temperature is the characteristic of induction heating rapid heat treatment.

Our company has many brands and wide resources, there is always one suitable for you. You only need to tell us your pipe manufacturing needs, our company will provide you with used welded pipe equipment that really suits your needs, welcome new and old customers to come to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province