Used round tube forming machines, the main points of welding quality (4)

- Sort:Information

- Auth:

- Source:

- Release time:2022-02-21 11:30

- Pvs:

【概要描述】There are many factors that affect the welding quality of used round tube forming machines, and these factors interact and restrict each other in the same system.

Used round tube forming machines, the main points of welding quality (4)

【概要描述】There are many factors that affect the welding quality of used round tube forming machines, and these factors interact and restrict each other in the same system.

- Sort:Information

- Auth:

- Source:

- Release time:2022-02-21 11:30

- Pvs:

There are many factors that affect the welding quality of used round tube forming machines, and these factors interact and restrict each other in the same system.

When one factor changes, other factors will also change as it changes. Therefore, in the high frequency adjustment, it is not enough to pay attention to the local adjustment of the frequency, power, current or squeeze amount of the used round tube forming machines.

This adjustment must be based on the specific conditions of the entire molding system, comprehensively considered from all aspects related to high-frequency welding, and adjusted by excluding all influencing factors one by one.

Below we break down the main factors in the high-frequency welding process, there are the following eight aspects, we will introduce the ⑦Impedance device in detail. ⑧Welding extrusion force

⑦ Impedance device in detail.

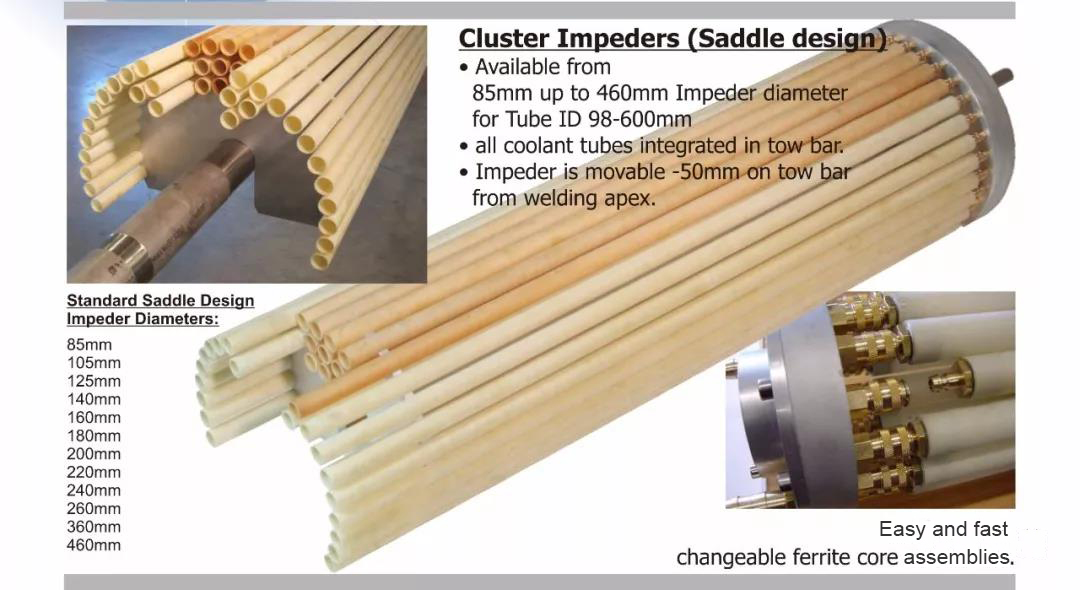

The function of the impedance device is to strengthen the skin effect and proximity effect of the high-frequency current. The impedance device is generally made of M-XO/N-XO type iron oxide, and is usually made into a magnet rod of φ10mm*(120-160)mm. Bundled in a heat-resistant, insulating shell, the inside is cooled by water.

The setting of the impedance device should match the pipe diameter to ensure the corresponding magnetic flux. To ensure the permeability of the resistor, in addition to the material requirements of the resistor, it is also necessary to ensure that the ratio of the cross-sectional area of the resistor to the cross-sectional area of the pipe diameter is large enough. In the production of high-precision high-grade pipes, it is required to remove internal burrs. The resistor can only be placed in the internal burr removal device, and the cross-sectional area of the resistor will be correspondingly smaller. At this time, the effect of using the concentrated fan layout of the magnetic rod is better than that of the ring. Layout.

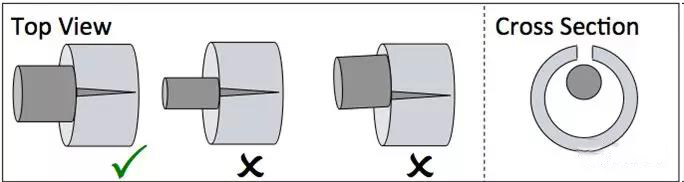

The distance between the resistor and the welding point also affects the welding efficiency. The gap between the resistor and the inner wall of the pipe is generally 6-15mm, and the upper limit value is used when the pipe diameter is large; the resistor should be placed concentrically with the pipe, and its head and the welding point The distance is 10-20mm, the same is true, when the pipe diameter is large, the larger value is used.

⑧Welding extrusion force

Welding pressure is also the main parameter of high frequency welding. Theoretical calculations believe that the welding pressure should be 100-300MPa, but the actual pressure in this area is difficult to measure in actual production. It is generally estimated based on experience and converted into the amount of squeeze on the edge of the pipe. Different wall thicknesses take different extrusion amounts. Usually, the extrusion amount below 2mm is: 0.5t~1t for 3-6mm; 0.5t for 6-10mm, and 0.3~0.5t for more than 10mm.

In the production of thick-walled pipes, such as API steel pipes, gray spot defects in welds often appear. Gray spot defects are refractory oxides. In order to eliminate gray spots, Baosteel and other manufacturers have adopted increased extrusion force to increase welding residuals. The method of measuring, the extrusion margin of 6mm or more steel pipes can reach the material thickness of 0.8~1.0, and the effect is very good.

Therefore, if you fully understand that the impedance device in detail and welding extrusion force will affect the welding quality of the used round tube forming machines, it is necessary to analyze other aspects of the welding quality of the used round tube forming machines before you can summarize the method and deal with it. The next issue will introduce Common problems in high frequency welding and their causes/solutions. If necessary, you can continue to pay attention to us.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province