Used round tube forming machines, the main points of welding quality (3)

- Sort:Information

- Auth:

- Source:

- Release time:2022-02-07 11:30

- Pvs:

【概要描述】There are many factors that affect the welding quality of used round tube forming machines, and these factors interact and restrict each other in the same system.

Used round tube forming machines, the main points of welding quality (3)

【概要描述】There are many factors that affect the welding quality of used round tube forming machines, and these factors interact and restrict each other in the same system.

- Sort:Information

- Auth:

- Source:

- Release time:2022-02-07 11:30

- Pvs:

There are many factors that affect the welding quality of used round tube forming machines, and these factors interact and restrict each other in the same system.

When one factor changes, other factors will also change as it changes. Therefore, in the high frequency adjustment, it is not enough to pay attention to the local adjustment of the frequency, power, current or squeeze amount of the used round tube forming machines.

This adjustment must be based on the specific conditions of the entire molding system, comprehensively considered from all aspects related to high-frequency welding, and adjusted by excluding all influencing factors one by one.

Below we decompose the main factors in the high-frequency welding process. There are the following eight aspects. We will introduce in detail the ⑤ Tube billet groove. ⑥Welding speed.

⑤ Tube billet groove

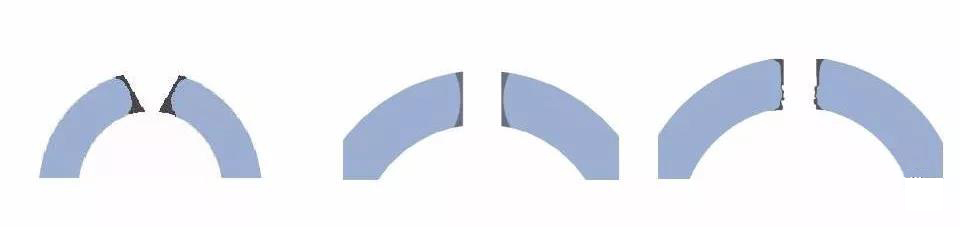

The groove of the tube blank is the cross-sectional shape. The general manufacturer directly enters the high-frequency welding material after the slitting, and the groove is in an "I" shape. When the thickness of the welding material is greater than 8-10mm, if this "I"-shaped groove is used, because of the curved arc, it is necessary to melt off the inner edge layer that the tube blank first contacts, thereby forming a very high inner edge. Burr, and it is easy to cause insufficient heating of the center layer and outer layer of the plate, which affects the welding strength of the high-frequency weld.

Therefore, when producing the back wall tube, the tube blank is best treated with edge planing or milling to make the groove in an "X" shape. Practice has proved that this kind of groove is very important for uniform heating and guaranteeing the quality of the weld.

At the same time, the choice of the groove shape also affects the adjustment of the meeting angle.

Welding joint design is a relatively weak link in welding engineering design, mainly because the knot groove design of many steel structural parts is not made by welding engineering and technical personnel, and grooves with rigid sets of standards and poor process performance are not uncommon. The groove form plays a very important role in controlling the internal quality of the weld and the manufacturing quality of the welded structure. The groove design must consider issues such as the fusion ratio of the base material, welding space, welding position and comprehensive economic benefits.

⑥ Welding speed

The forming speed of the welded pipe unit is restricted by the high-frequency welding speed and sawing speed. Generally speaking, the unit speed can be driven faster, reaching 100 meters per second, and the high-frequency can also increase the speed by increasing the power.

However, for steel plates over 10mm, the forming speed produced by domestic units can actually only reach 8-12 meters per second.

The welding speed affects the welding quality. When the welding speed is increased, it is beneficial to shorten the heat-affected zone and extrude oxide from the molten groove; on the contrary, when the welding speed is very low, the heat-affected zone becomes wider, which will produce larger welding burrs and thicken the oxide layer. The weld quality has deteriorated.

Therefore, it is necessary to fully understand the tube billet groove and welding speed will affect the welding quality of the used round tube forming machines, then it is necessary to analyze the other aspects of the welding quality of the used round tube forming machines in order to summarize the method and deal with it. The next issue will introduce ⑦impedance device in detail. ⑧Welding extrusion force. If necessary, you can continue to pay attention to us.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province